Nanosheet self-assembly ferrocobalt hydroxide and preparation method thereof

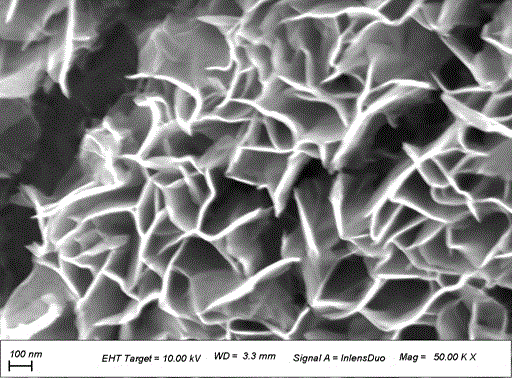

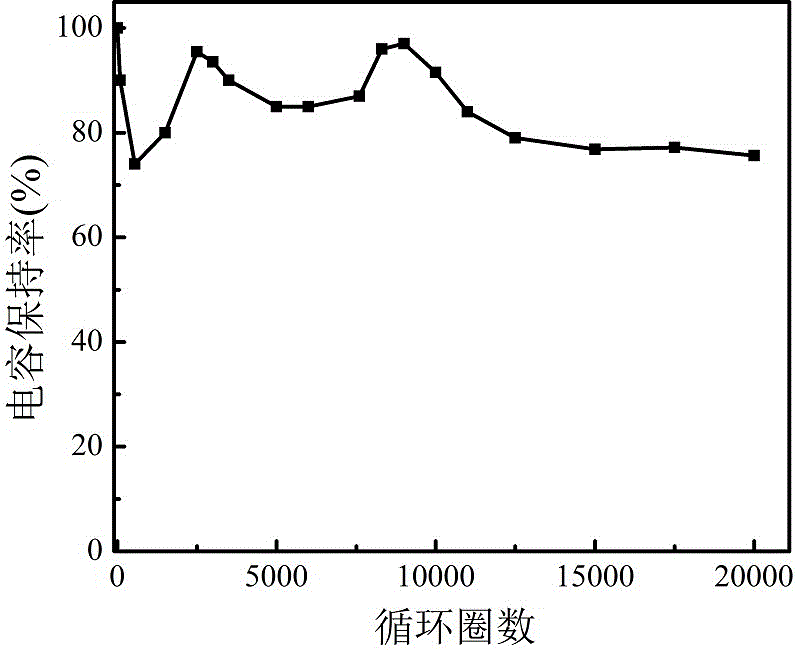

A hydroxide and self-assembly technology, which is applied in the preparation of nanosheet self-assembled cobalt-iron hydroxide, in the field of nanosheet self-assembled cobalt-iron hydroxide, can solve the problem that the electrochemical characteristics of nanosheet cobalt-iron hydroxide need to be improved , production cost and product efficiency are difficult to meet at the same time, to achieve the effects of low cost, increased stability, and increased active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A nanosheet self-assembled honeycomb structure cobalt-iron hydroxide and a preparation method thereof, comprising the steps of:

[0030] S1, with Co 2+ , Fe 3+ , NO 3 - Preparation of electrodeposition solutions for solute ions;

[0031] S2. Immerse the porous nickel foam and the graphite sheet as the cathode and the anode in the electrodeposition solution respectively, the deposition voltage is 1.9-3.0V, and the time is 30-200s;

[0032] S3. Rinse the electrodeposited product prepared in step S2 with ultrapure water, and then put it into an ultrasonic cleaner for oscillating cleaning at full power for 3-5 minutes.

[0033] S4, drying the sample prepared in S3 to obtain nanosheet self-assembled honeycomb structure cobalt-iron hydroxide.

[0034] The preparation system includes two processes, one of which is chemical deposition reaction and the other is electrochemical reaction. When the electrification starts, when the current passes through the positive and negat...

Embodiment 1

[0048] The preparation method of the nanosheet self-assembled honeycomb structure cobalt-iron hydroxide of the present embodiment comprises the following steps:

[0049] S1. Prepare Co(NO 3 ) 2 , Fe(NO 3 ) 3 Mixed solution, where Co 2+ with Fe 3+ The concentration ratio of 2:1 is used as the electrodeposition solution;

[0050] S2, the porous nickel foam (size: 1cm × 3cm) is used as the cathode, and the double-layer graphite sheet is placed in the electrodeposition solution as the anode, and a supercapacitor tester is used to carry out the deposition experiment. The deposition voltage is 2.0V, and the deposition time is 120s;

[0051] S3. Rinse the electrodeposited product prepared in step S2 with ultrapure water, and then put it into an ultrasonic cleaner for oscillating cleaning at full power for 3 to 5 minutes;

[0052] S4. Dry the sample prepared in S3 at 30° C. for 6 hours in a blower box.

Embodiment 2

[0054] The steps of this embodiment are exactly the same as those of Embodiment 1, the difference is that in step S1, Co 2+ with Fe 3+ The concentration ratio is 1:1; in step S2, the deposition voltage is 2.1V, and the deposition time is 240s; in step S4, the drying temperature is 50°C, and the drying time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com