Preparation method of ultraviolet-curable graphene dispersion liquid

A technology of graphene dispersion and ultraviolet light, which is applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous fillers, etc., can solve the problems of inability to remove organic solvents, poor interface compatibility, etc., and achieve less defects, Gentle conditions, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

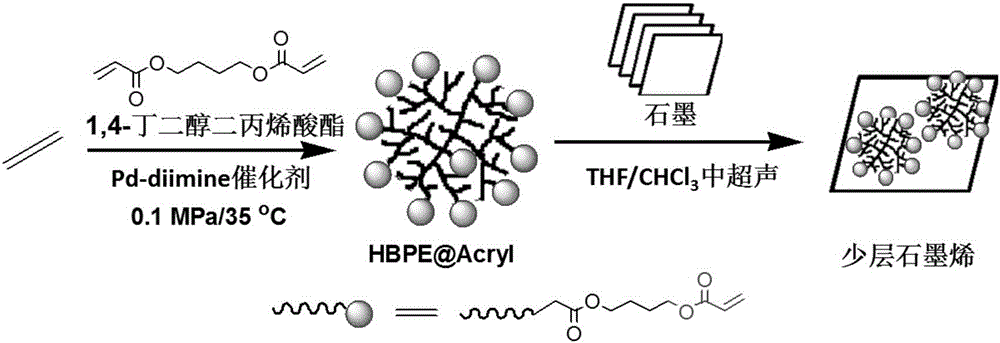

Method used

Image

Examples

Embodiment 1

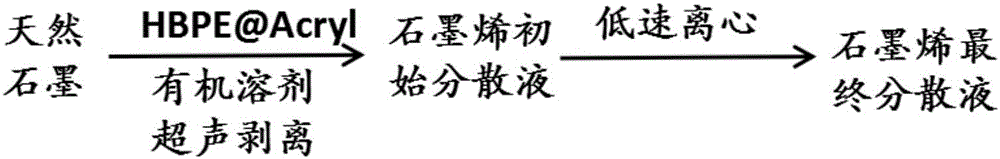

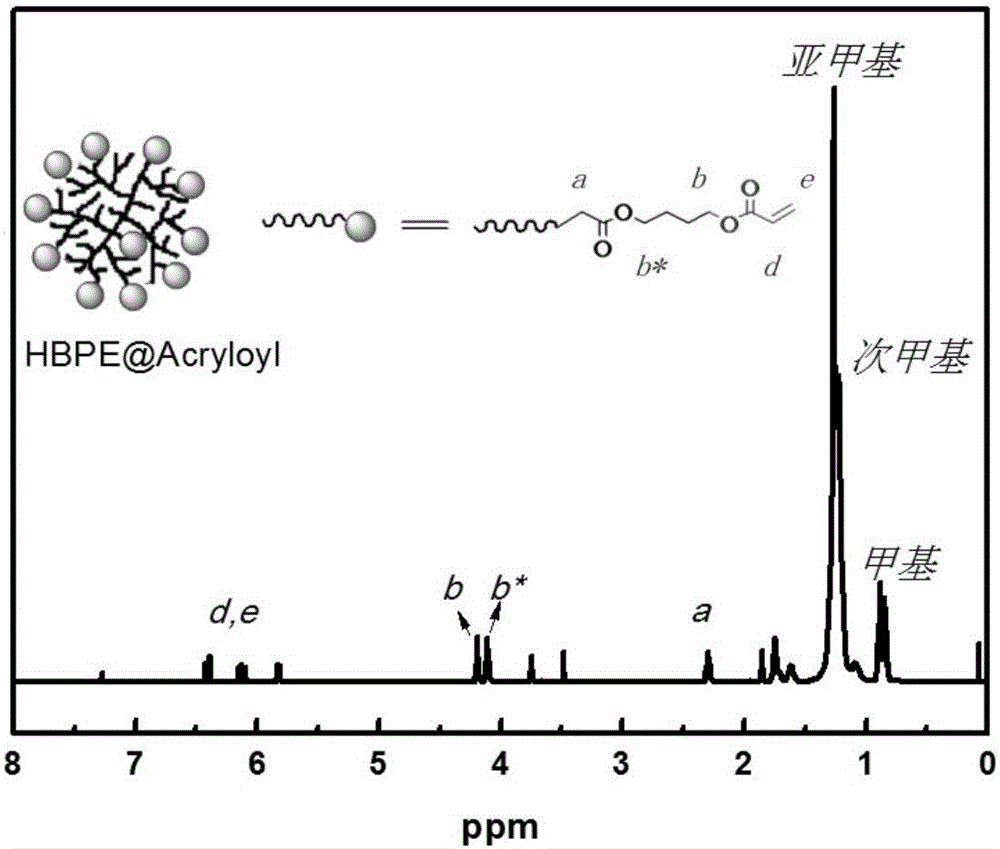

[0043]Step 1: Under the protection of ethylene gas, add 90mL of anhydrous dichloromethane and 9.911g of 1,4-butanediol diacrylate into a 250mL double-layer bottle, stir at 25°C for 30min; then add Anhydrous dichloromethane solution of Pd-diimine (0.2 g of Pd-diimine catalyst dissolved in 10 mL of anhydrous dichloromethane). The reaction temperature was controlled at 25° C., the ethylene pressure was 0.1 MPa, and the reaction was stirred for 24 hours. After the reaction, the reaction solution was transferred into 200 mL of 2 wt.% acidified methanol solution to terminate the reaction. The solvent was removed by blowing cold air with a blower, and the polymer was dissolved in 50 mL of dichloromethane solution, 5 drops of concentrated hydrochloric acid and 5 drops of hydrogen peroxide were added, and stirred for 2 hours to dissolve a small amount of residual Pd particles, and then 150 mL of methanol was added to precipitate the product. The polymer was further dissolved with tetr...

Embodiment 2

[0046] The first step: the preparation and purification process of HBPE@Acryl is the same as the first step in Example 1 to obtain pure HBPE@Acryl.

[0047] Step 2: Add 20 mg of HBPE@Acryl (synthesized by the above step 1), 20 mg of graphite (Sigma-Aldrich product, product number 332461) and 10 mL of tetrahydrofuran solvent (analytical grade) into a 20 mL thick glass test tube, place in a low-speed rotating After being placed on the shelf, it was placed in a 300W ultrasonic pool for 48 hours at room temperature. The resulting product was centrifuged at 4000rpm for 45min to get the upper graphene solution. Observe the appearance of the graphene solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com