Sulfonic acid type waterborne polyurethane-acrylate self extinction resin and preparation method and application thereof

A water-based polyurethane and acrylate technology, applied in the field of acrylate-modified water-based polyurethane resin, can solve the problems of decreased rubbing and friction resistance, increased brittleness of the coating, and single structure, and achieves improved wear resistance and microscopic roughness. The effect of increasing the degree of production and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

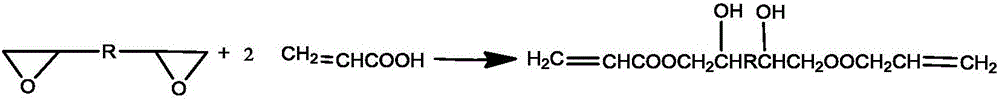

Method used

Image

Examples

Embodiment 1

[0097] Add 300g epoxy resin E51, 1.65g catalyst triphenylphosphine, 0.205g polymerization inhibitor p-methoxyphenol MEHQ, 2.47g yellowing additive triphenyl phosphite TPP in the three-necked flask, and the temperature rises to 90- 95 degrees, and then add 110.2 g of acrylic acid dropwise within 1 hour until the acid value drops below 0.5 mgKOH / g to obtain the desired compound epoxy acrylate.

Embodiment 2

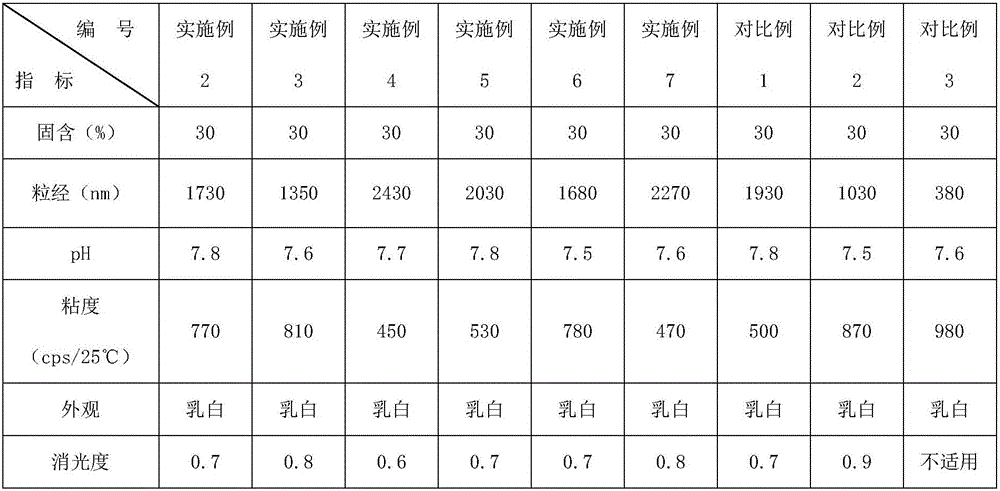

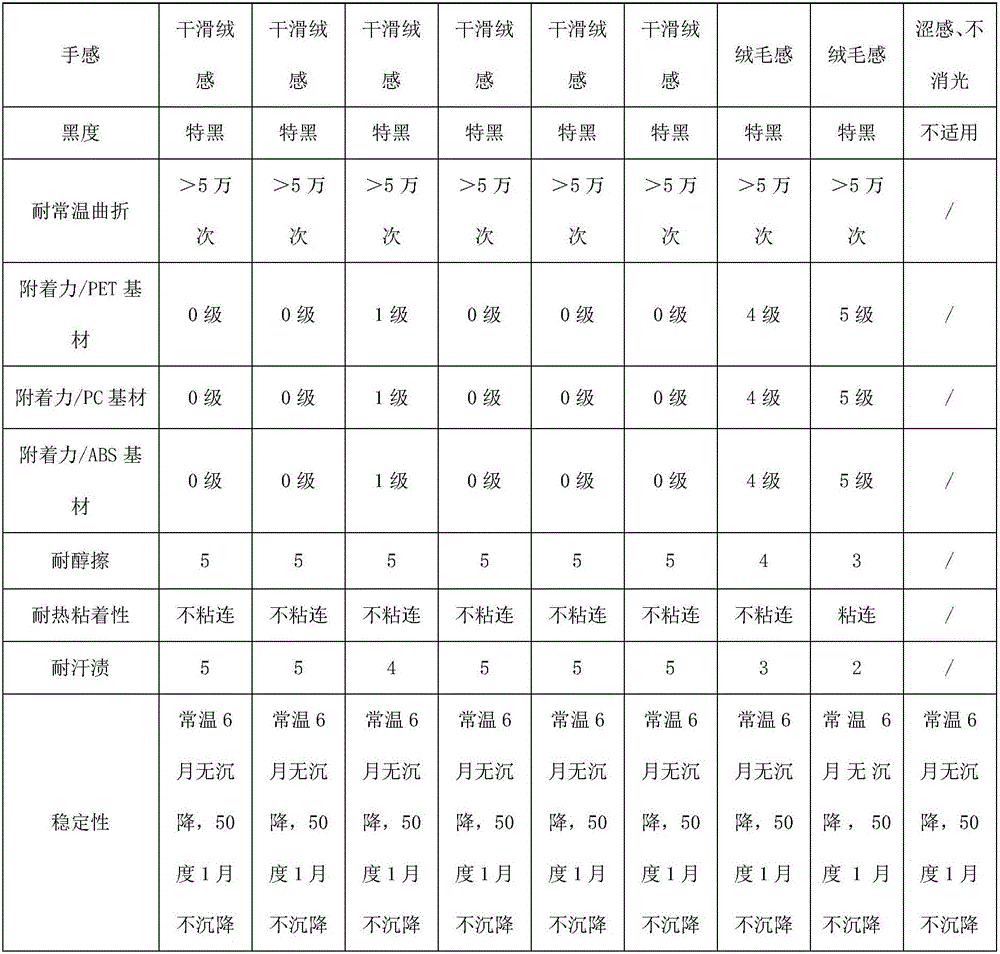

[0099]Add 40g of HMDI, 26g HDI, 240g CMA-654, 23.8g epoxy acrylate obtained according to Example 1, 4g MPEG1200, 3g neopentyl glycol, react at 80 degrees, take samples to monitor NCO during the experiment, until NCO reaches the theoretical value of 1.81%, cool down to 60 445g of acetone and 171g of methyl methacrylate were added and stirred for 5min, and 2.2g of ethylenediamine and 3.5g of A95 was diluted with 23g of deionized water, added and stirred at 45°C for 25 minutes, and 487g of water was added under the condition of shear dispersion to obtain a water-based polyurethane-acrylate mixed emulsion. The system was heated up to 45 degrees, and 0.26g of tert-butyl hydroperoxide and 0.26g of sodium hydrosulfite (sodium dithionite) were added to initiate polymerization. The polymerization was stirred at this temperature for 3 hours, and the acetone was distilled off the emulsion under reduced pressure to obtain a solid content of 50wt %, a white sulfonic acid type water-ba...

Embodiment 3

[0101] Add 74g HMDI, 47.5g HDI, 190gCMA-654, 37g epoxy acrylate obtained according to Example 1, 5.2gMPEG1200, 16.5g neopentyl glycol, reacted at 80 degrees, sampling and monitoring NCO during the experiment, until NCO reached 4.73% of theoretical value, cooled to Add 306g of acetone and 382g of methyl methacrylate at about 60 degrees and stir for 5 minutes, mix 8g of ethylenediamine and 4g A95 was diluted with 48g of deionized water, added and stirred at 45°C for 25 minutes, and 712g of water was added under the condition of shear dispersion to obtain a water-based polyurethane-acrylate mixed emulsion. The system was heated up to 45 degrees, and 0.76g of tert-butyl hydroperoxide and 0.76g of sodium hydrosulfite (sodium dithionite) were added to initiate polymerization. The polymerization was stirred at this temperature for 3 hours, and the acetone was distilled off the emulsion under reduced pressure to obtain a solid content of 50wt %, a white sulfonic acid type water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com