Micro-nano copper powder and preparation method thereof

A micro-nano, copper powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the performance of the reduction process is difficult to control well, the preparation repeatability is not ideal, and the product is conductive. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0094] (1) Weigh 0.15 g of copper chloride and dissolve it in 500 mL of water to make a solution, add 224 g of potassium hydroxide under strong stirring conditions, and keep stirring for 4 hours at 60 ° C to obtain system A;

[0095] (2) Weigh 0.2 g of citric acid, 3 g of ascorbic acid, 0.5 mL of ammonia water, 0.1 g of PVA, 0.3 g of lysine and 10 mL of methanol and dissolve them in 200 mL of water, add them to system A to obtain system B, and put system B at 90 ° C Under the conditions, the reaction was continued for 48 hours, the reaction was stopped, the reactants were centrifuged, washed repeatedly, and finally dried in a vacuum oven to obtain a sample-copper powder A.

[0096] Adopt scanning electron microscope to observe the morphology of sample-copper powder A, the result sees figure 1 ,From figure 1 It can be seen that the copper particles...

Embodiment 2

[0098] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0099] (1) Weigh 6.0 grams of copper chloride and dissolve it in 500 mL of water to make a solution, add 340 grams of potassium hydroxide under strong stirring conditions, and keep stirring for 4 hours at 60°C to obtain system A;

[0100] (2) Weigh 3.2 grams of citric acid, 50 grams of ascorbic acid, 30 grams of maltose, 1 mL of ammonia water, 2 mL of diethylenetriamine, 1 gram of PVA and 15 mL of ethanol and dissolve them in 200 mL of water, and add them to system A to obtain system B. Under the condition of 90°C, the reaction was continued for 48h. The reaction was stopped, and the reactants were centrifuged, washed repeatedly, and finally dried in a vacuum oven to obtain a sample-copper powder B.

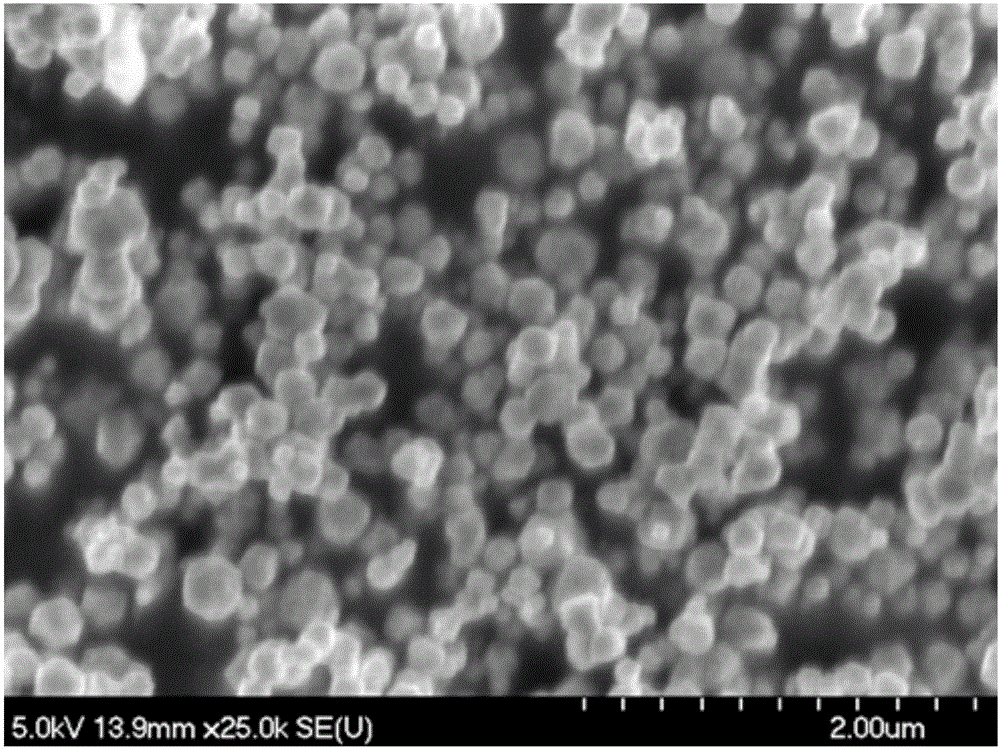

[0101] Adopt scanning electron microscope to observe the morphology of sample-copper powder B, the results can be found in figure 2 ,From figure ...

Embodiment 3

[0103] The preparation method of a kind of micronano copper powder of the present embodiment, it comprises the following steps:

[0104] (1) Weigh 125 grams of copper sulfate and dissolve it in 1000 mL of water to make a solution, add 400 grams of sodium hydroxide, 10 grams of sodium carbonate and 6 grams of urea under strong stirring conditions, and continue stirring for 12 hours at 60 ° C to obtain System A;

[0105] (2) Weigh 50 grams of D-xylose, 340 grams of lactose, 200 grams of sucrose, 10 grams of ammonium chloride, 5 grams of glutamic acid, 3 grams of PEG and 30 mL of ethanol, dissolve them in 1000 mL of water, add them to system A to obtain the system B, the temperature of system B was rapidly raised to 130°C by microwave heating, the reaction was continued for 2 minutes, and the reaction was stopped. The reactant was filtered, washed repeatedly, and finally dried in a vacuum oven to obtain sample-copper powder C.

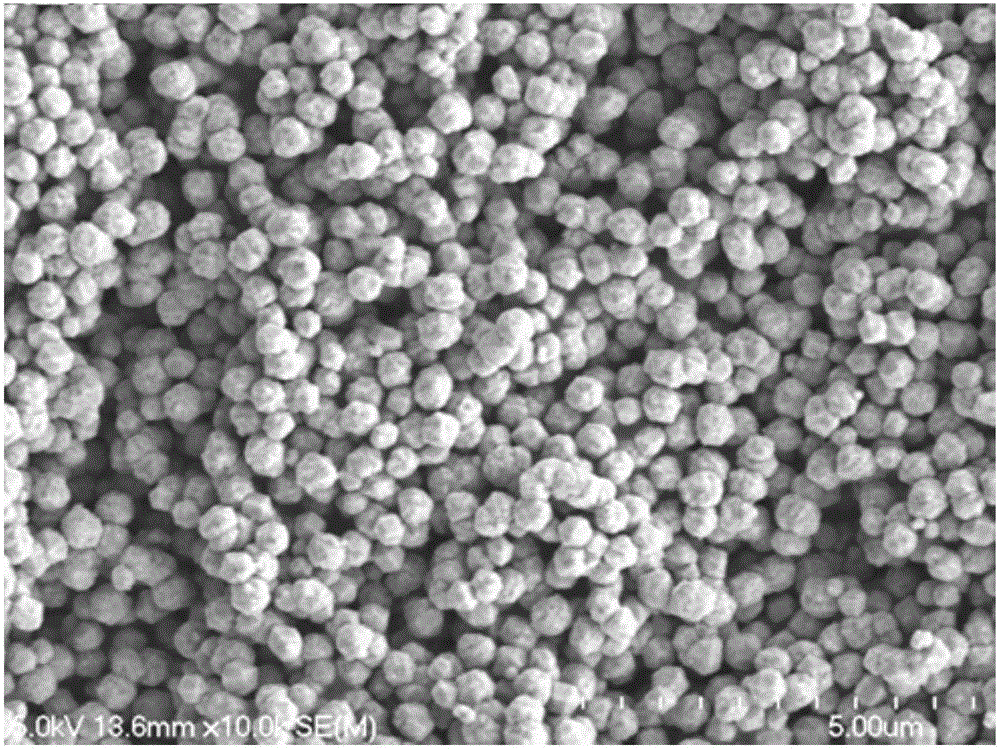

[0106] Adopt scanning electron microscope to obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com