Ultraviolet light curing machine

A technology of ultraviolet light and curing machine, which is applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the complex mechanical and control mechanism, can not fully meet the requirements of adhesive layer thickness control, and high manufacturing cost problem, to achieve the effect of low manufacturing cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

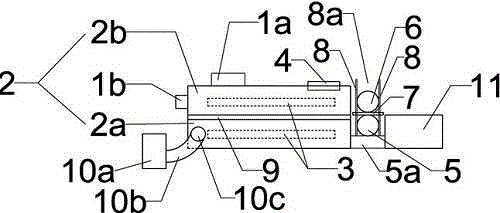

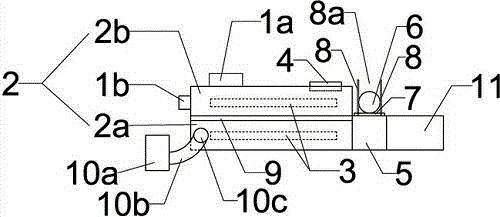

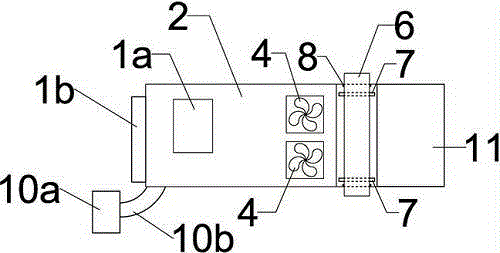

[0040] figure 1 , 3, 4, and 5, the ultraviolet light curing machine includes an ultraviolet light curing device and a thickness control device, wherein the ultraviolet light curing device includes a power supply 1a, a housing 2, and at least one ultraviolet light source 3 arranged in the housing 2 And the heat dissipation assembly arranged on the housing 2 . The housing 2 includes a base 2a and an upper cover 2b, the base 2a and the upper cover 2b can be fastened to form a space in the shell; the thickness control device includes a lower limit body 5, an upper limit body 6 and a thickness adjustment member 7, at least one thickness adjustment member 7 Placed on the lower limiting body 5 , the upper limiting body 6 is placed on the thickness adjusting member 7 , the thickness adjusting member 7 forms a gap equal to the thickness of the thickness adjusting member 7 between the lower limiting body 5 and the upper limiting body 6 .

[0041] The power supply 1a includes a transfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com