Double-air inner suction type feed crusher

A pulverizer and feed technology, applied in feed, agricultural machinery and tools, food science, etc., can solve the problems of large space occupation, large size, low work efficiency, etc., and achieve the effect of improving work efficiency and increasing the export area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

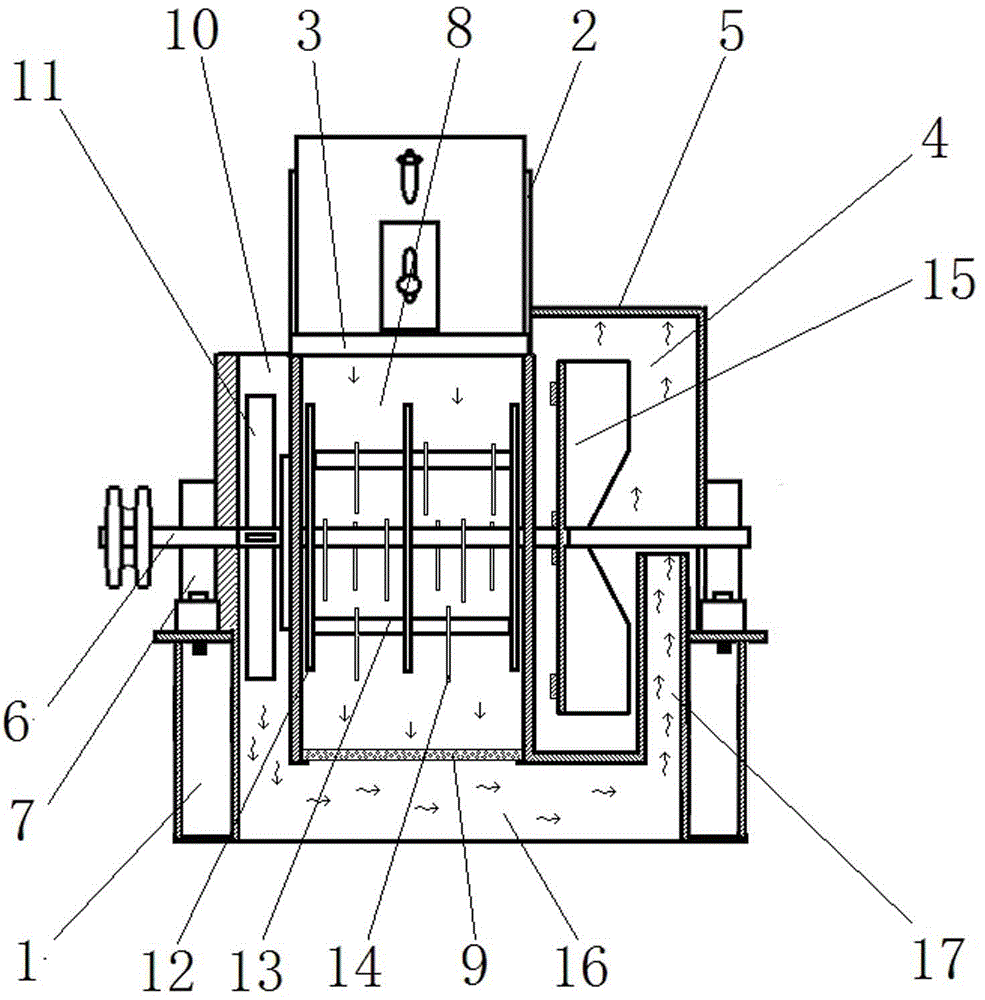

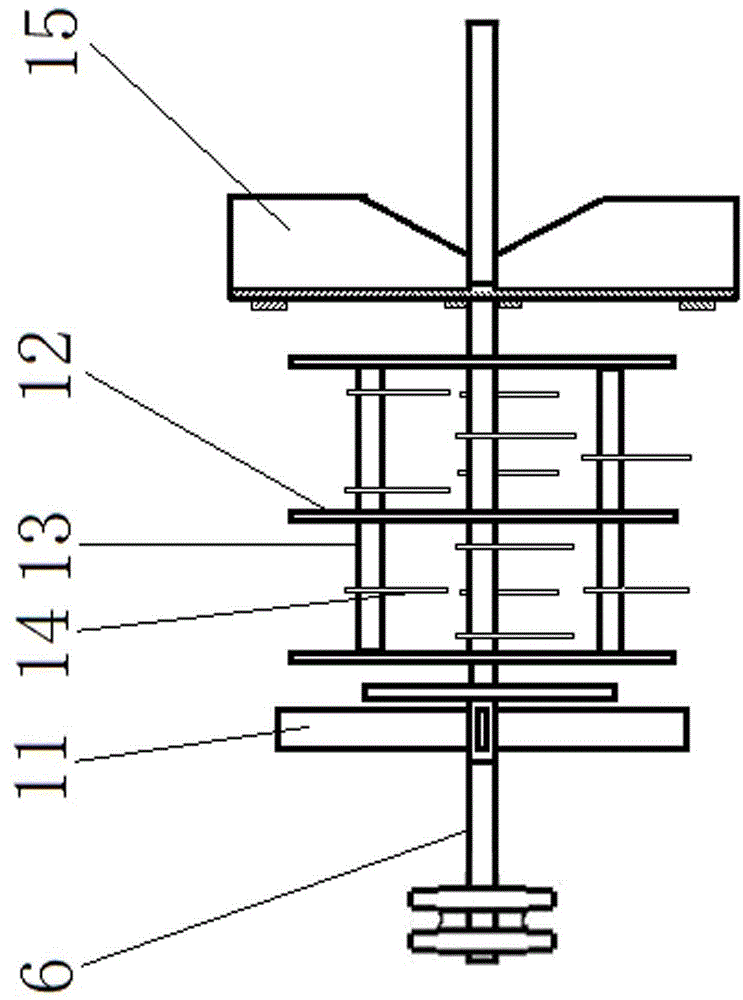

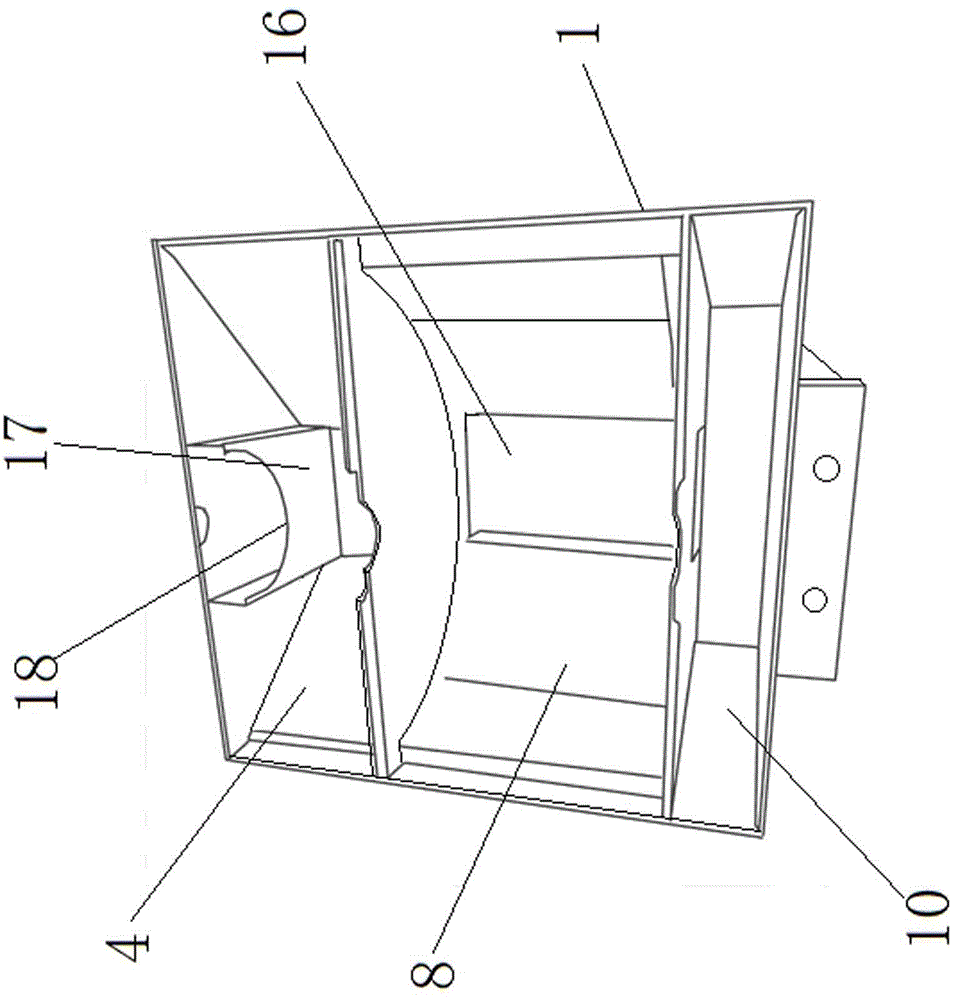

[0020] Example 1 : Double air internal suction feed grinder consists of square machine base 1, casing 2, feed port 3, discharge pipe 4, discharge port 5, main shaft 6, bearing seat 7, fan, crushing bin 8, filter mesh 9 composition. Wherein the machine base 1 is covered with an organic casing 2, the feed port 3 is arranged above the casing 2, the discharge pipe 4 is arranged on the side inside the machine base 1, the main shaft 6 runs through the blast chamber 10 in the machine base 1, and The warehouse 8, the discharge pipe 4, and the casing 2 are correspondingly fastened on the machine base 1 to form a complete and relatively airtight blast chamber 10, the crushing chamber 8 and the discharge pipe 4, and the two ends of the main shaft 6 pass through the bearing seat 7 Fixed on the base 1, the main shaft 6 passes through the part of the blast chamber 10 and is equipped with a blowing blade group 11. When the power is turned on, the motor drives the main shaft 6 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com