Method for recovering and recycling waste positive electrode material during production process of lithium iron phosphate battery

A lithium iron phosphate battery and production link technology, applied in battery recycling, recycling technology, battery electrodes and other directions, can solve problems such as poor performance of lithium iron phosphate materials, short service life of battery packs, and hidden safety hazards, and achieve recycling and repair. Simple process, easy recycling, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

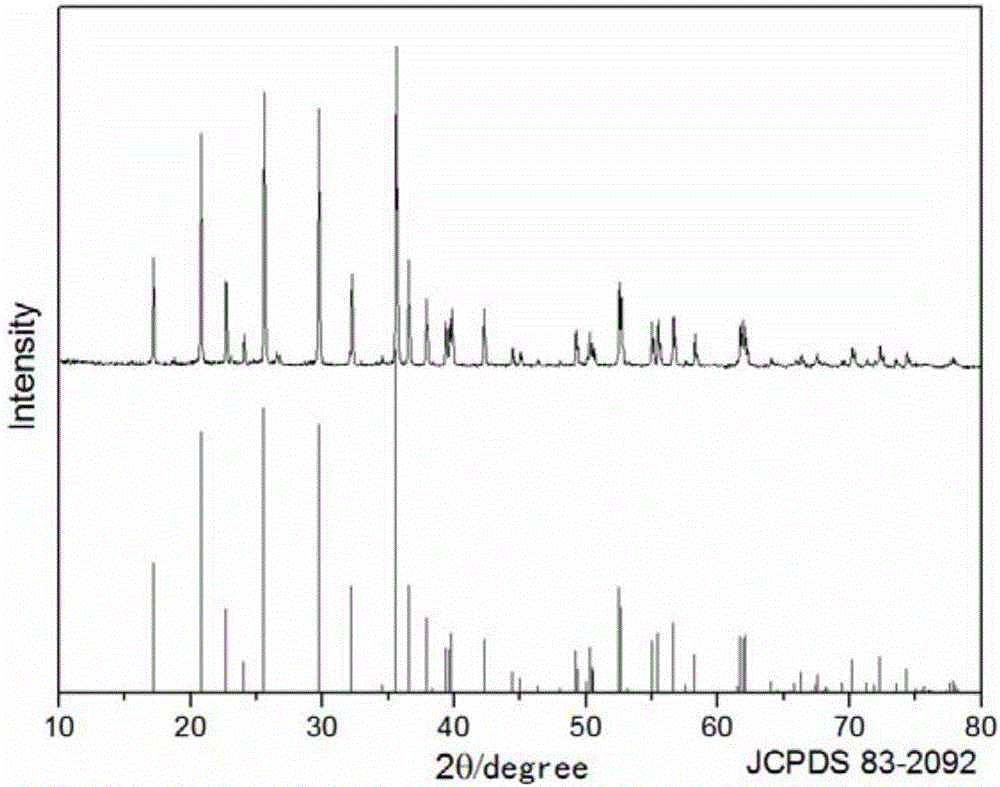

Image

Examples

Embodiment 1

[0042] (1) Put 500g of waste lithium iron phosphate positive electrode into 500mL of 0.05mol / L sodium hydroxide solution, soak for 10 minutes and start stirring. After the material is completely separated from the aluminum foil, remove the aluminum foil;

[0043] (2) filtering and washing mixed materials such as lithium iron phosphate, conductive agent, binding agent remaining in the lye of step (1);

[0044] (3) Put the lithium iron phosphate mixed material washed in step (2) into an oven at 80° C. for 24 hours to dry.

[0045](4) ball milling the dried lithium iron phosphate mixed material in step (3), the ball milling speed is 500rpm, and the powder after ball milling is sieved by vibration, using a 500-mesh screen;

[0046] (5) Soak the lithium iron phosphate mixed material powder obtained in step (4) in NMP, stir and ultrasonically treat for 4 hours, and remove the binder therein;

[0047] (6) After filtering and drying the lithium iron phosphate material obtained in ste...

Embodiment 2

[0052] (1) Put 500g of waste lithium iron phosphate positive electrode into 500mL 0.5mol / L potassium hydroxide solution, soak for 10 minutes and start stirring, and remove the aluminum foil after the material is completely separated from the aluminum foil;

[0053] (2) filtering and washing mixed materials such as lithium iron phosphate, conductive agent, binding agent remaining in the lye of step (1);

[0054] (3) Put the lithium iron phosphate mixed material washed in step (2) into an oven at 100° C. for 24 hours;

[0055] (4) ball milling the dried lithium iron phosphate mixed material in step (3), the ball milling speed is 400rpm, and the powder after ball milling is sieved by vibration, using a 400-mesh screen;

[0056] (5) Soak the lithium iron phosphate mixed material powder obtained in step (4) in DMF, stir and sonicate for 2 hours, and remove the binder therein;

[0057] (6) After filtering and drying the lithium iron phosphate material obtained in step (5), place it...

Embodiment 3

[0062] (1) First put 500g of waste lithium iron phosphate positive electrode into 500mL of 1mol / L sodium hydroxide solution, soak for 10min and start stirring, and remove the aluminum foil after the material is completely separated from the aluminum foil.

[0063] (2) Filtrating and washing the remaining mixed materials such as lithium iron phosphate, conductive agent and binder in the lye of step (1).

[0064] (3) Put the lithium iron phosphate mixed material washed in step (2) into an oven at 80° C. for 24 hours to dry.

[0065] (4) Perform ball milling on the dried lithium iron phosphate mixed material in step (3), the ball milling speed is 600 rpm, and the powder after ball milling is sieved by vibration, using a 600-mesh sieve.

[0066] (5) Soak the lithium iron phosphate mixed material powder obtained in step (4) in DMF, stir and sonicate for 1 hour, and remove the binder therein;

[0067] (6) After filtering and drying the lithium iron phosphate material obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com