Ceramic sound absorbing material and preparing method and usage thereof

A technology of sound-absorbing materials and ceramics, which is applied in the field of ceramic sound-absorbing materials and their preparation, can solve problems such as fire prevention, weather resistance, strength, sound absorption and sound insulation, etc., to solve the problem of noise pollution, physical and chemical properties Excellent, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

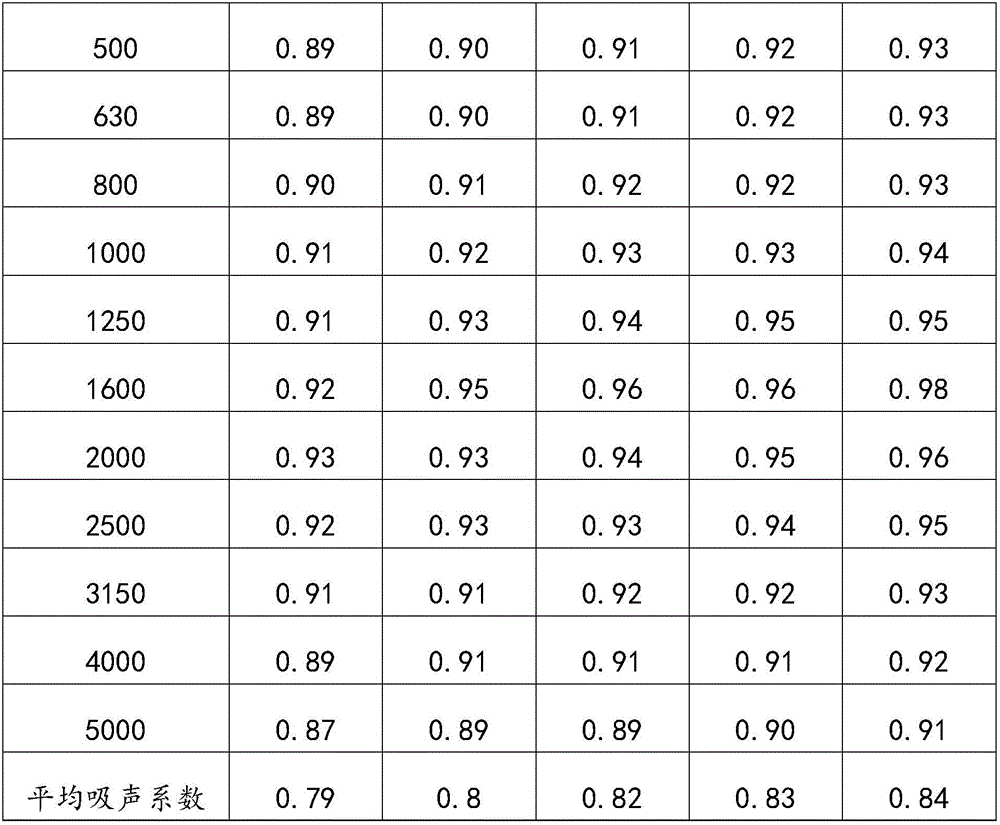

Image

Examples

preparation example Construction

[0059] In the preparation method of the above-mentioned ceramic sound-absorbing material, the raw materials are mixed in proportion, followed by a foaming process, and then sintered to obtain a ceramic sound-absorbing material.

[0060] The preparation method of the ceramic sound-absorbing material of the present invention has the advantages of simple process, low cost, short time consumption and easy implementation.

[0061] Preferably, the corundum, silicon carbide, cordierite and silicate are pulverized and mixed with a ball mill first, and then mixed with other raw materials.

[0062] By means of ball milling, the solid raw materials can be further fully crushed and mixed; as needed, some water can be added in an appropriate amount, which is included in the total amount of water used.

[0063] Further preferably, the ball milling time is 2-48 hours, which is determined according to the particle size and dosage of the specific raw materials used.

[0064] After ball millin...

Embodiment 1

[0078] A method for preparing a ceramic sound-absorbing material, comprising the steps of:

[0079] (1) 20kg corundum powder, 20kg silicon carbide powder, 20kg cordierite powder and 5kg sodium silicate powder are fully ground and mixed by ball milling;

[0080] (2) Add 5kg polyethylene oxide, 25kg water, and 1kg fatty alcohol polyoxyethylene ether sodium sulfate to the material obtained in step (1), stir and mix thoroughly, keep warm at 70°C for 30 minutes, and stir the obtained material at a stirring rate of 1000rpm for 15min , then poured into the mold (thickness is 1cm);

[0081] (3) After drying and demolding the material obtained in step (2) (natural drying, demoulding after surface molding), heat preservation at 1600° C. for 120 minutes, and sintering to obtain a ceramic sound-absorbing material.

Embodiment 2

[0083] A method for preparing a ceramic sound-absorbing material, comprising the steps of:

[0084] (1) 30kg corundum powder, 30kg silicon carbide powder, 30kg cordierite powder and 10kg magnesium silicate powder are fully ground and mixed by ball milling;

[0085] (2) Add 10kg polyoxyethylene, 35kg water, 2kg fatty alcohol polyoxyethylene ether sodium sulfate to the material obtained in step (1), fully stir and mix, keep warm at 90°C for 10 minutes, and stir the obtained material at a stirring rate of 2000rpm for 5min , then poured into the mold (thickness is 1cm);

[0086] (3) After drying and demoulding the material obtained in step (2) (natural drying, demoulding after surface molding), heat preservation at 1900° C. for 30 minutes, and sintering to obtain a ceramic sound-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com