An environmentally friendly freeze-thaw resistant permeable pavement pavement material and preparation method thereof

A technology for paving materials and permeable pavement, applied in the field of chemical building materials, can solve the problems such as the inability to give full play to the superior performance of the drainage pavement, the small drainage area of the drainage pipe, and the untimely drainage, and achieve obvious energy conservation and environmental protection, and reduce damage and impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

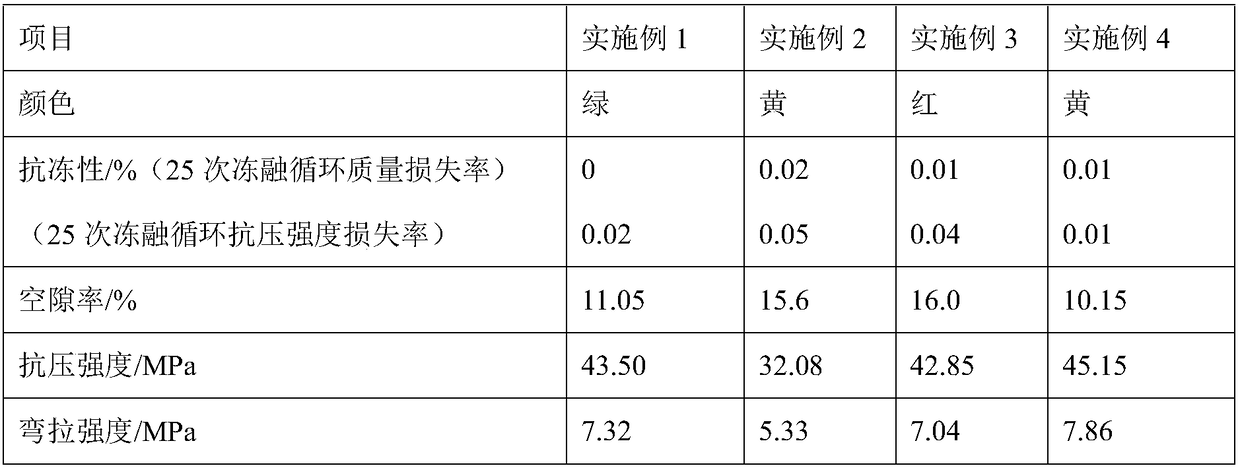

Examples

Embodiment 1

[0023] The environmentally friendly freeze-thaw resistant permeable pavement pavement material consists of three components A, B, and C, and its preparation method is as follows:

[0024] 1) Preparation of component A: in parts by mass, add 6 parts of stone, 3 parts of waste concrete granules, and 1 part of rubber granules into the mixer in sequence, at a speed of 50 rpm, stir for 5 minutes to obtain component A, pack storage;

[0025] 2) Preparation of component B: in parts by mass, 9 parts of bisphenol A epoxy resin E-51, 1.5 parts of elastic modifier QS-P24F, 0.1 part of thixotropic organic bentonite, 0.1 part of BYK-066N , BYK-163 0.1 part, phthalocyanine green 0.2 part, antioxidant 1076 0.1 part, antioxidant additive 1075 0.1 part, add to the mixer in turn, the speed is 400-800 rpm, stir for 5 minutes to get B component, packaging storage;

[0026] 3) Preparation of component C: in parts by mass, add 9.8 parts of polyetheramine curing agent D230, 0.1 part of curing acce...

Embodiment 2

[0029] The environmentally friendly freeze-thaw resistant permeable pavement pavement material consists of three components A, B, and C, and its preparation method is as follows:

[0030] 1) Preparation of component A: in parts by mass, add 5 parts of stone, 4 parts of waste concrete granules, and 1 part of rubber granules into the mixer in turn, at a speed of 50 rpm, stir for 5 minutes to obtain component A, pack storage;

[0031] 2) Preparation of component B: in parts by mass, 8.3 parts of bisphenol A epoxy resin E-44, 2 parts of elastic modifier QS-P24F, 0.1 part of thixotropic agent hydrogenated castor oil, 0.1 part of BYK-066N, Add 0.1 part of BYK-163, 0.2 part of benzidine yellow, 0.1 part of antioxidant 1076, and 0.1 part of antioxidant adjuvant 1075 into the mixer in turn at 400-800 rpm, stir for 5 minutes to obtain component B, pack storage;

[0032]3) Preparation of component C: in parts by mass, 9.8 parts of polyetheramine curing agent D400, 0.1 part of curing ac...

Embodiment 3

[0035] The environmentally friendly freeze-thaw resistant permeable pavement pavement material consists of three components A, B, and C, and its preparation method is as follows:

[0036] 1) Preparation of component A: in parts by mass, add 5 parts of stone, 3 parts of waste concrete granules, and 2 parts of rubber granules into the mixer in turn, at a speed of 50 rpm, stir for 5 minutes to obtain component A, pack storage;

[0037] 2) Preparation of component B: in parts by mass, 9.3 parts of bisphenol A epoxy resin E-51, 1 part of elastic modifier QS-P24F, 0.1 part of thixotropic organic bentonite, 0.1 part of BYK-066N, BYK 0.1 part of -163, 0.2 part of permanent red, 10760.1 part of antioxidant, and 0.1 part of antioxidant additive 1075 were added to the mixer in sequence at a speed of 400-800 rpm, stirred for 5 minutes to obtain component B, packaged and stored;

[0038] 3) Preparation of component C: in parts by mass, add 9.8 parts of polyether amine curing agent D230, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com