Riser used for casting cast piece as well as manufacturing method thereof and application thereof

A casting and riser technology, applied in the field of shrinkage, can solve the problems of increasing manufacturing costs and uneven levels of the foundry industry, and achieve the effects of increasing the yield, reducing the shrinkage of the refiring line, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

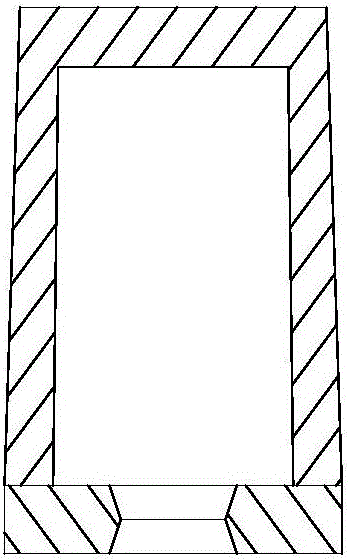

Image

Examples

Embodiment Construction

[0012] 75% of casting coated sand (70 / 140 mesh) produced by Dalin is used as heat insulation refractory material, 5% of 100 mesh magnesium powder is used as induced heat material, and 20% of high-efficiency coal powder (≥100 mesh) in Inner Mongolia is used , the high volatile content is used as insulation material to replace the insulation riser currently used in foundries.

[0013] Production process: first make a hot core box

[0014] Mix the coated sand, magnesium powder and coal powder according to the above ratio for 2-3 minutes, then add them to the sand bucket of the hot core machine, and when the hot core box is heated to 180-230°C, close the mold and shoot the sand, and the curing time is 60s , coring.

[0015] The test results show that the feeding efficiency of the new insulation riser is the same as that of the expanded perlite type insulation riser currently used in the factory, and the casting cost is only 20% of the cost of the original purchase of the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com