A method for regulating the electrical properties of indium oxide nanofiber field effect transistors

A field effect transistor and nanofiber technology, which is applied in the field of transistor electrical performance regulation, can solve problems such as metal doping that have not yet been seen, and achieve the effects of easy large-scale industrial production, reduction of off-state current, and reliable principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

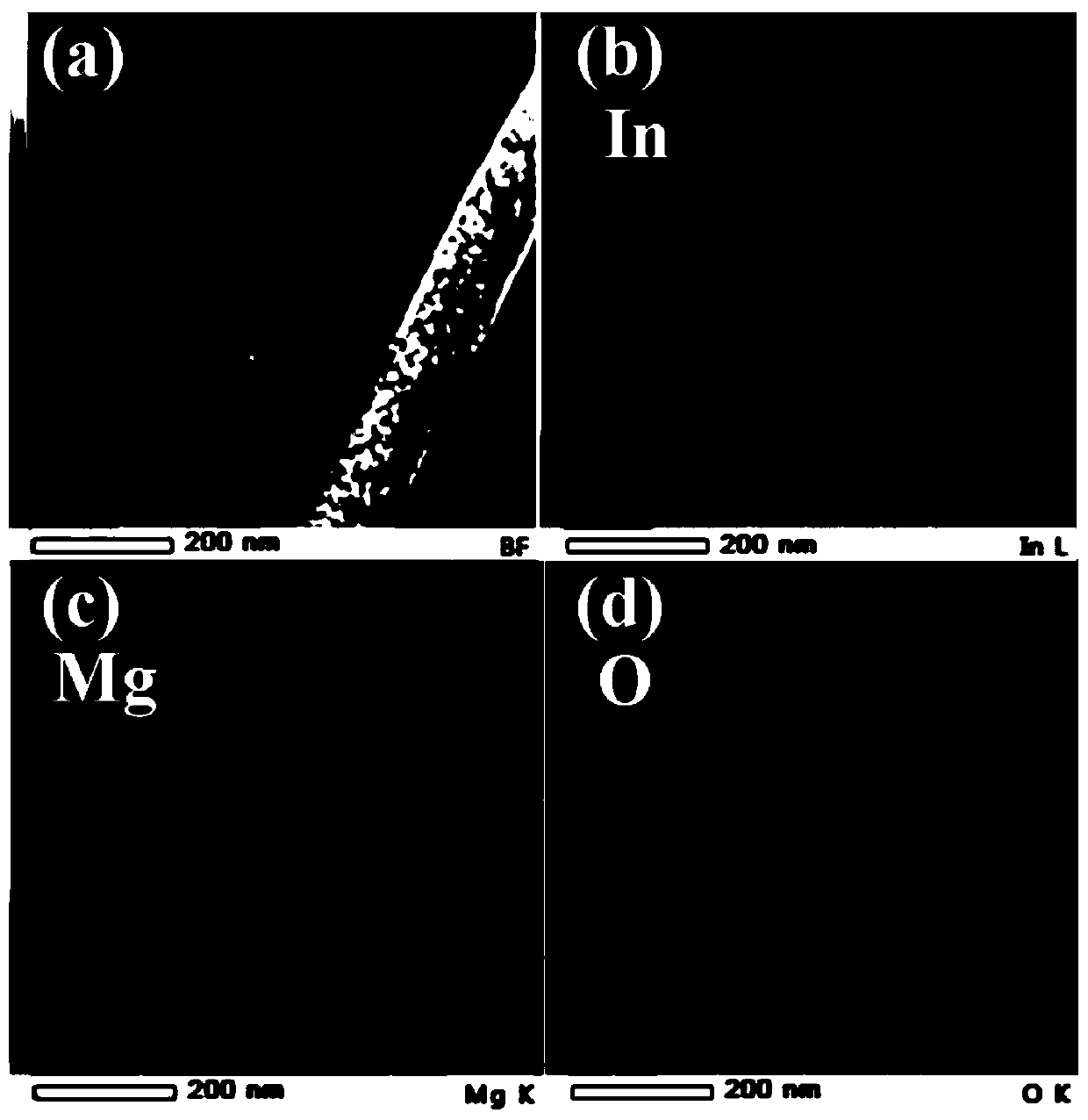

[0025] (3)In 2 o 3 Preparation of NFs and assembly of devices: extract 5ml of the solution prepared in step (1) or step (2), and pass the existing electrospinning technology (voltage 10-25kv, humidity 20-50%, the distance between the needle tip and the receiving substrate 10-20cm, solution propulsion speed 0.5-1ml / h) Spin the electrospinning precursor solution of pure In source or doped electrospinning precursor solution to cover the surface with 150-300nm SiO 2 In is prepared on a silicon wafer or ITO or FTO conductive glass with a dielectric layer 2 o 3 Nanofibers (In 2 o 3 NFs) or metal doped In 2 o 3 Nanofibers (In 2 o 3 NFs), and then attach the resulting In 2 o 3 Nanofibers (In 2 o 3 NFs) or metal doped In 2 o 3 Nanofibers (In 2 o 3 NFs) silicon wafers or conductive glass are baked on a baking table for 10-60 minutes, annealed by an ultraviolet lamp for 20-60 minutes, then placed in a muffle furnace for 400-600°C for 1-3 hours, and cooled naturally to Ta...

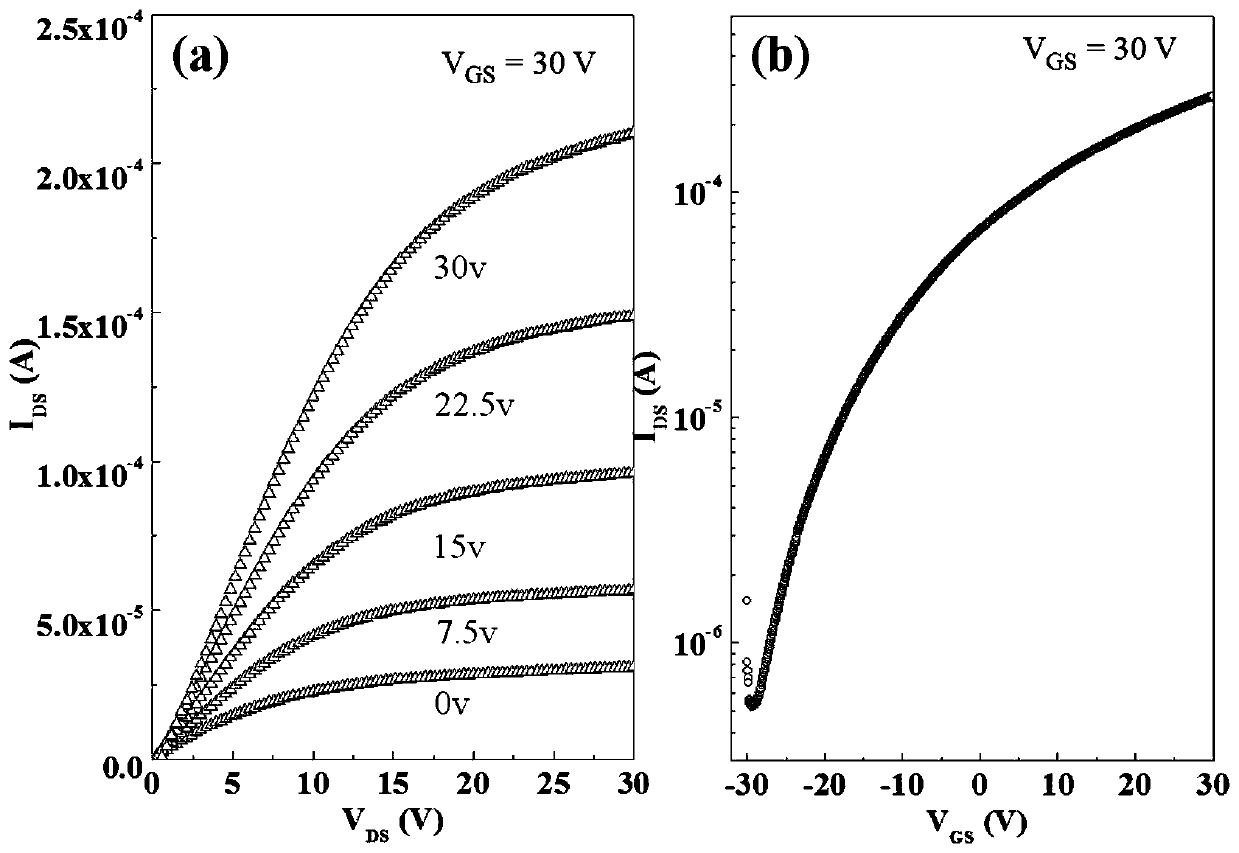

Embodiment 1

[0028] This example prepares In 2 o 3 The specific process of NFFETs is:

[0029] (1) Preparation of electrospinning precursor solution: 6g of polyvinylpyrrolidone (PVP), 0.8g of indium trichloride tetrahydrate, 40g of N, N-dimethylformamide (DMF) were mixed in a glass bottle, and magnetically The stirrer is fully stirred until the solution is uniform and transparent, forming a pure In source electrospinning precursor solution;

[0030] (2) Assembly of the device: extract 5ml of the pure In source electrospinning precursor solution prepared in step (1), and use the electrospinning technology (voltage 10-25kv, humidity 20-50%, the distance between the needle tip and the receiving substrate to be 10 -20cm, solution propulsion speed 0.5-1ml / h), the pure In source electrospinning precursor solution is spun to cover the surface with 150-300nm SiO 2 Dielectric layer silicon wafer or ITO or FTO conductive glass to get In 2 o 3 NFs, which will then be attached to In 2 o 3 The s...

Embodiment 2

[0032] This example prepares 2%-Mg doped In 2 o 3 The specific process of NFs and NFFETs is:

[0033] (1) Preparation of electrospinning precursor solution: 6g of polyvinylpyrrolidone (PVP), 0.8g of indium trichloride tetrahydrate, 40g of N, N-dimethylformamide (DMF) were mixed in a glass bottle, and magnetically The stirrer is fully stirred until the solution is uniform and transparent, forming a pure In source; electrospinning precursor solution;

[0034] (2) Preparation of doped electrospinning precursor solution: take 0.016 g of magnesium chloride hexahydrate and dissolve it in the electrospinning precursor solution of pure In source configured in step 1 to form a doped Mg doping ratio of 2 wt%. Electrospinning precursor solution;

[0035] (3) Assembly of the device: extract 5ml of the doped electrospinning precursor solution prepared in step (2), and use electrospinning technology (voltage 15kv, humidity 30%, distance from needle tip to receiving substrate 15cm, soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com