Double electric layer capacitor and organic electrolyte for double electric layer capacitor

An electric double layer capacitor and organic electrolyte technology, applied in the direction of hybrid capacitor electrolyte, etc., can solve the problem of failure to improve the working voltage of the electric double layer capacitor, affecting the high current charge and discharge of the electric double layer capacitor, and no mass commercial production, etc. problems, to achieve the effect of improving the withstand voltage window, wide application temperature range, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

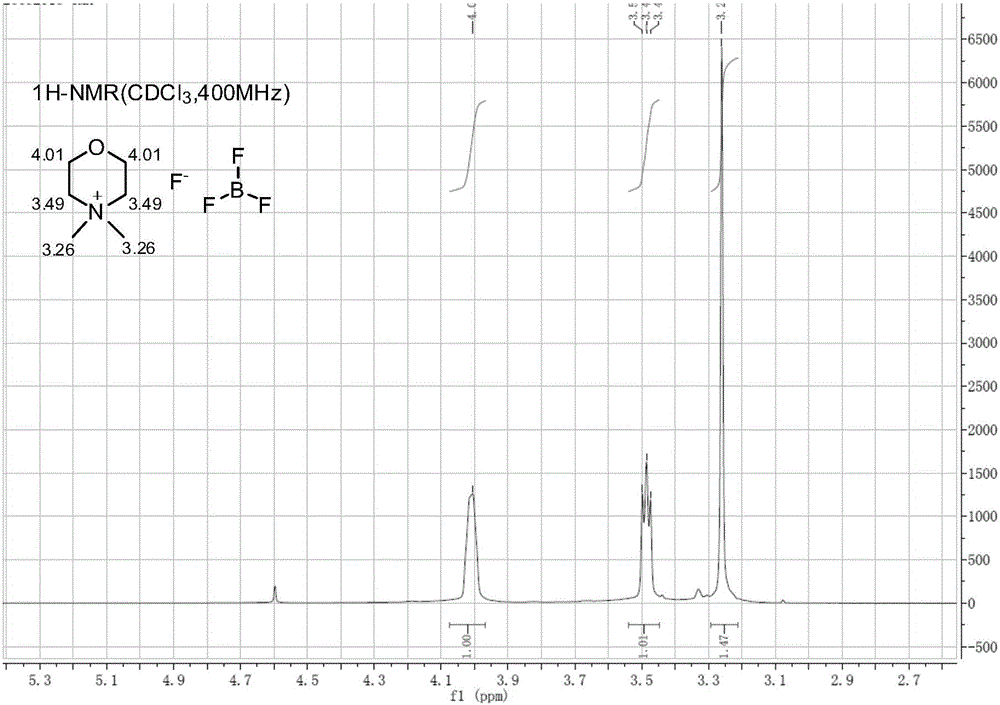

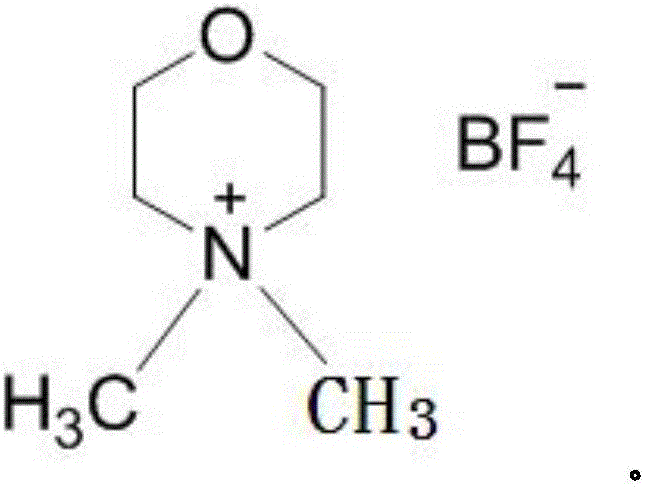

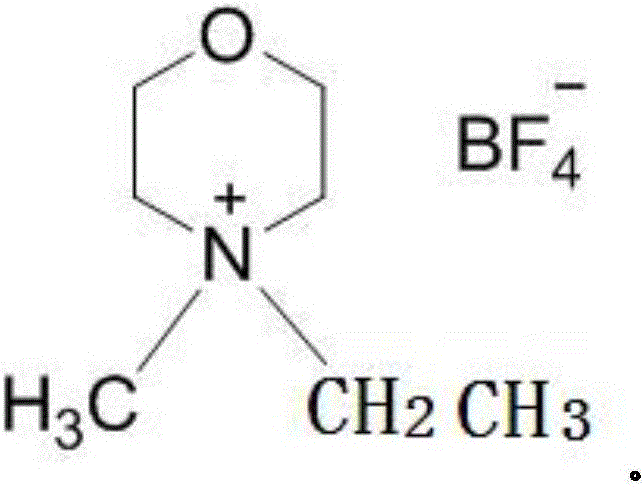

[0030] Since the molecular radius is the key indicator of the electrolyte salt, the reduction of the molecular radius helps to increase the utilization rate of the micropores of the supercapacitor electrode material, increase the adsorption area and thus increase the electrostatic capacity, and the decomposition voltage of the electrolyte salt directly determines the withstand voltage of the electrolyte. performance. For this reason, we first conduct QSAR quantitative structure-activity relationship (QSAR) research and calculation on the electrolyte salt to be developed, screen out electrolyte salts with smaller molecular radii for synthesis, and then measure the electrochemical window. The two data show that MOR 1,R -BF 4 series of electrolytes compared to TEA-BF of conventional commercial electrolytes 4 、TEMA-BF 4 It has great advantages. See Table 1 for the comparison of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com