Novel normal-pressure heat conducting oil furnace

A heat-conducting oil furnace and normal pressure technology, applied in the field of boilers, can solve the problems of poor thermal stability of heat-using equipment, energy waste, environmental pollution, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

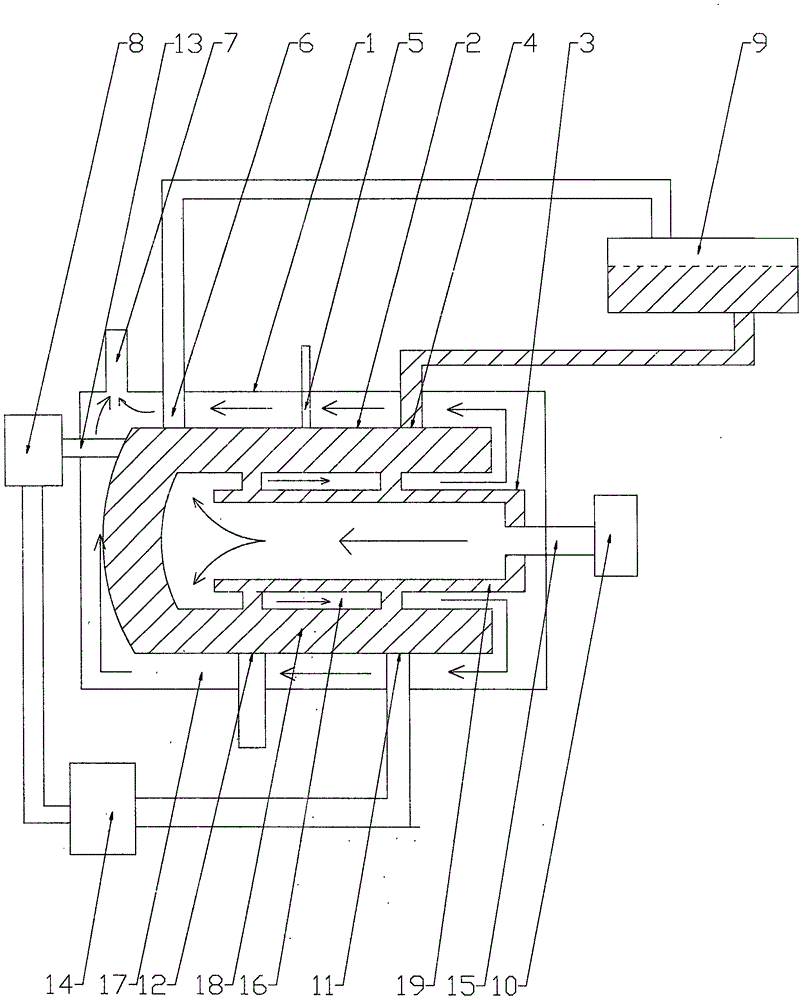

[0014] Such as figure 1 As shown, a new type of normal-pressure heat-conducting oil furnace includes a furnace body 1, a heat-conducting oil tank 2, a combustion chamber 3, a high-temperature oil pump 8, a burner 10, and a high-level oil tank 9. The heat-conducting oil tank 2 and the combustion chamber 3 are located in the furnace body 1, the high-temperature oil pump 8, burner 10 and high-level oil tank 9 are located outside the furnace body 1, the upper opening of the high-level oil tank 9 communicates with the atmosphere, and the high-level oil tank 9 contains heat transfer oil, and the heat transfer oil tank 2 is open at one end The heat-conducting oil tank 2 lies horizontally in the furnace body 1, the first oil cavity 18 is between the inner wall and the outer wall of the heat-conducting oil tank 2, the combustion chamber 3 is a hollow cylinder with one end open, and the other end of the combustion chamber 3 passes through The combustion channel 15 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com