High-speed spinning method of polylactic acid fiber

A polylactic acid fiber, high-speed spinning technology, applied in the direction of melt spinning, stretch spinning, fiber treatment, etc., can solve the problem that the film layer is easy to fall off the roll surface, the effect of the cohesion of the tow, and the tendency to affect the orientation of the tow, etc. problems, to achieve the effect of meeting the requirements of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

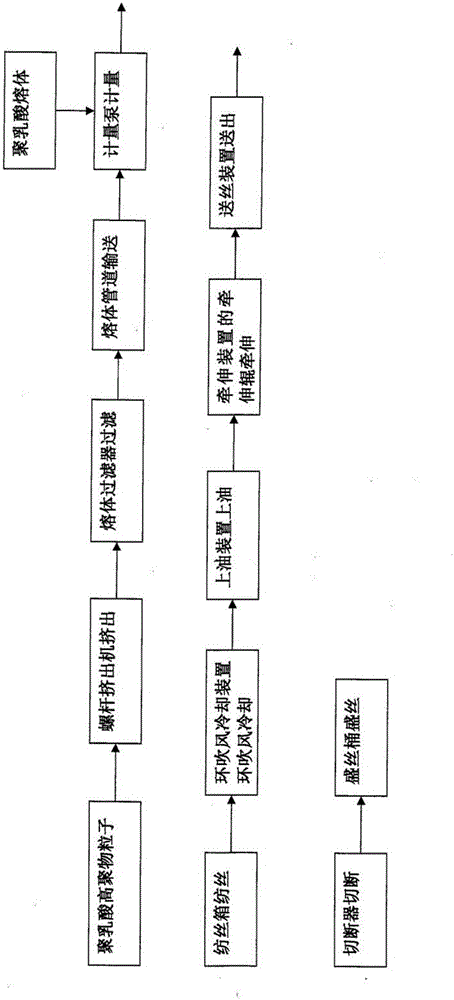

[0043] The spinning material used in this embodiment is polylactic acid polymer particles (also known as "polylactic acid slices" in the industry). according to figure 1 As shown in the process flow, the process of the high-speed spinning method for polylactic acid fibers of the present invention is: introducing polylactic acid polymer particles into a screw extruder for melt extrusion, filtering through a melt filter, and then introducing into a metering pump through a melt pipeline , after metering by the metering pump, it is introduced into the spinning box for spinning, and it is sprayed out from the spinneret hole on the spinneret plate of the spinning assembly of the spinning box. After the cooling and oiling device is oiled, it is drafted by the drafting roller of the drafting device, and then by the guide roller 50 ( Figure 9 shown) into the wire feeding device, sent out from the wire feeding device and cut by the cutter, then introduced into the wire holding barrel...

Embodiment 2

[0079] Only the polylactic acid polymer particles were changed to polylactic acid melt, and directly introduced into the metering pump, so compared to Example 1, the screw extruder and melt pipeline (also called melt pipeline) were omitted, and the rest were the same Description of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com