Thermal forming laminated water-cooling mold for high-strength steel plate

A high-strength steel plate, thermoforming technology, used in forming tools, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult maintenance, poor mold strength, etc., achieve high pressure holding capacity, improve cooling efficiency, and improve the effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings in the embodiments of the present invention. Apparently, the described embodiments are only some examples of the present invention, not all of them.

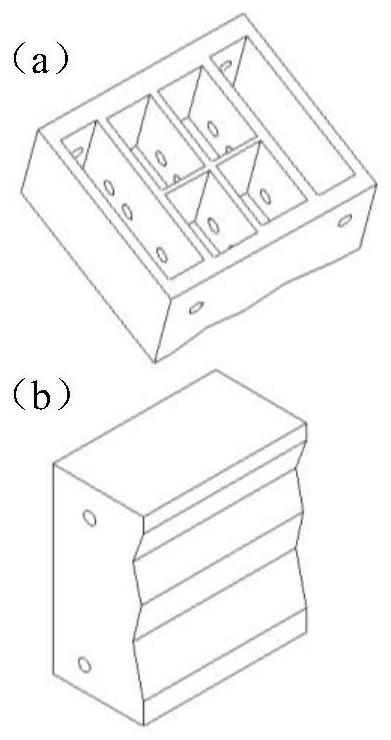

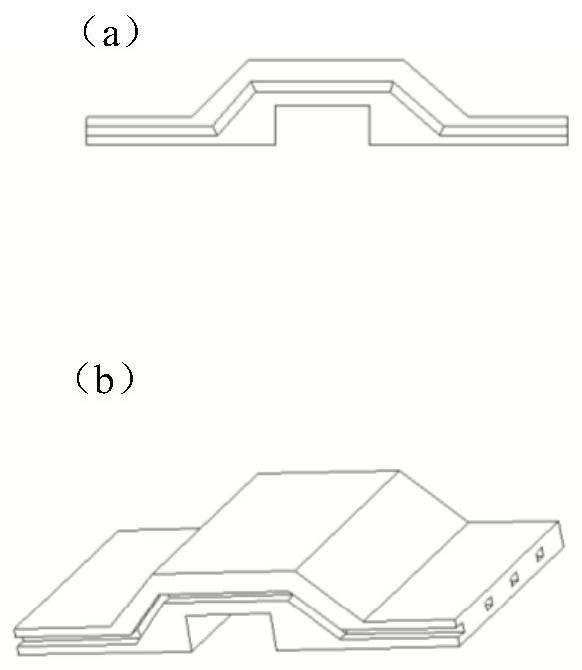

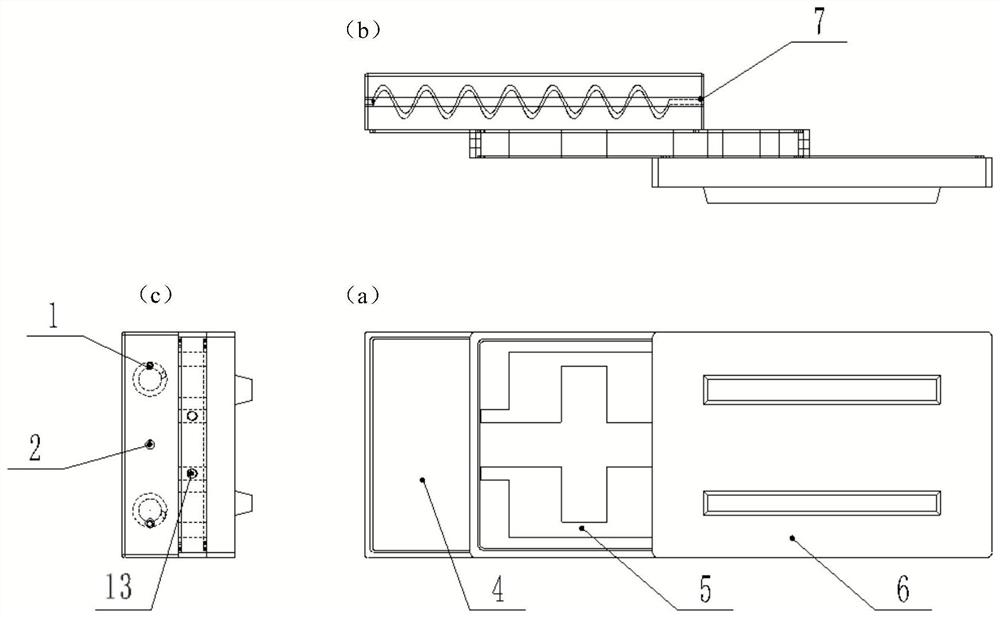

[0029] Such as image 3 As shown, the mold includes the lowermost mold layer 4, the middle mold layer 5, and the uppermost mold layer 6, which are stacked closely from bottom to top, between the lowermost mold layer 4 and the middle mold layer 5, and between the middle mold layer 5 and the uppermost mold layer 6. All of them are slidingly embedded through the mortise and tenon structure.

[0030] Such as Figure 5 As shown, there are spiral cooling pipes and linear pipes inside the bottom layer 4 of the mold, and the two ends of the spiral cooling pipes and straight pipes respectively pass through the end surfaces on both sides of the bottom layer 4 of the mold.

[0031] The end faces of both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com