Cellulase-producing bacillus licheniformis and application thereof

A technology of Bacillus licheniformis and cellulase, which is applied in the field of microorganisms, can solve the problems of insignificant treatment effect of microbial inoculants, large labor input, influence on farmers' enthusiasm, etc., and achieves broad market application prospects, long shelf life, easy transportation and convenient transportation. stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

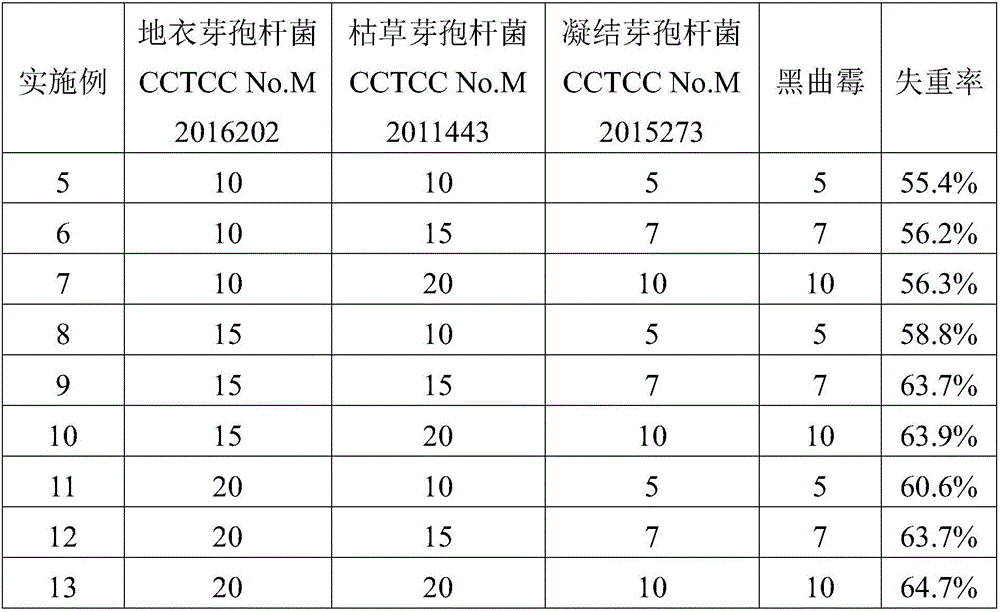

Examples

Embodiment 1

[0023] Example 1 Screening of Bacillus licheniformis CCTCC No.M 2016202

[0024] Collect 1g of soil sample from a paddy field in Wuxi, Jiangsu, add it to 99ml of sterile saline, shake it on a shaker at 37°C for 10min, and the shaker speed is 150rpm; absorb 1ml of liquid and add CMC (sodium carboxymethylcellulose) as the only carbon In the liquid medium of the source, continue shaking culture at 37°C and 150rpm; after 24 hours, draw 1ml of the liquid and add it to the liquid medium with CMC (sodium carboxymethylcellulose) as the only carbon source, at 37°C, Continue shaking culture at 150rpm for 24hrs; after 24hrs, absorb 1ml of liquid and add it to the liquid medium with CMC (sodium carboxymethylcellulose) as the sole carbon source, and continue shaking culture at 37°C and 150rpm for 24hrs. This was repeated three times for enrichment culture. Finally, after gradient dilution of the culture solution, spread on a plate medium with CMC (sodium carboxymethylcellulose) as the sol...

Embodiment 2

[0027] Example 2 Identification of Bacillus licheniformis CCTCC No.M 2016202

[0028] 1. Colony morphology

[0029] After the strain was cultured on LB medium at 37°C for 24 hrs, round colonies were formed with irregular edges; Gram staining was positive; under optical microscope observation, the bacterial cells were long rod-shaped, single, paired or chain-like.

[0030] 2. Physiological and biochemical identification

[0031] Physiological and biochemical identification is carried out to the screened bacterial strain in embodiment 1, and the results are as shown in table 1:

[0032] Table 1 Physiological and biochemical identification results of cellulase-producing strains

[0033] project result project result Athletic + Oxidase + spore + Methyl red + Grow at 37°C + V-P determination + anaerobic growth + indole production - glucose + Catalase + citrate utilization + propionate utilization + ...

Embodiment 3

[0037] Example 3 Determination of Cellulase Production Ability of Bacillus licheniformis CCTCC No.M 2016202

[0038] Cellulase production test medium (g / L): maltose 40, peptone 10, NaCl 5, K 2 HPO 42. Microbial culture conditions: liquid volume 15mL / 250mL Erlenmeyer flask, shaker temperature control 37°C, rotation speed 180rpm, culture time 48hr. Determination of cellulase activity by CMC method (Wu Wentao, Ju Meiting, Liu Jinpeng, etc., Isolation, Identification and Degradation Characteristics of a Cellulose Degrading Bacteria Strain to Corn Stalk. Microbiology Bulletin, 2013, 40(4): 712-719) . Bacillus licheniformis CCTCC No.M 2016202 was used as the test bacteria, and Bacillus licheniformis CCTCC No.M 2012458 was used as the control bacteria.

[0039] After measurement, the enzyme activity of Bacillus licheniformis CCTCC No.M 2016202 fermentation liquid is 98.5U / mL, and the enzyme activity of control bacterial strain Bacillus licheniformis CCTCC No.M 2012458 fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com