Bagged edible mushroom material and preparation method thereof

A technology of edible mushroom bag and bag material, which is applied in the direction of botany equipment and method, application, organic fertilizer, etc., and can solve the problems of inability to improve product quality, high cost, and inability to promote early fruiting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

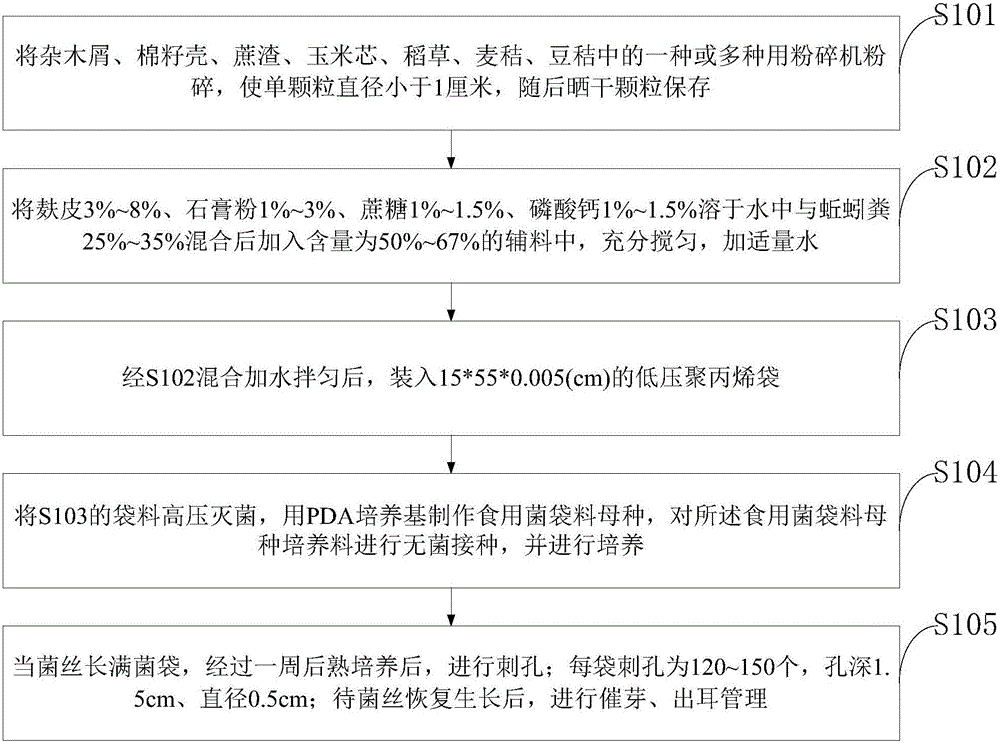

[0024] Such as figure 1 As shown, the preparation method of the edible mushroom bag material that the embodiment of the present invention provides comprises the following steps:

[0025] S101: Pulverize one or more of miscellaneous wood chips, cottonseed hulls, bagasse, corncobs, rice straw, wheat straw, and bean straw, so that the diameter of a single particle is less than 1 cm, and then dry the particles for storage;

[0026] S102: Dissolve 3%-8% of bran, 1%-3% of gypsum powder, 1%-1.5% of sucrose, and 1%-1.5% of calcium phosphate in water, mix them with 25%-35% of vermicompost, and add 50% %~67% of the auxiliary materials, fully stir, add appropriate amount of water;

[0027] S103: After mixing in S102 and adding water, put it into a 15*55*0.005(cm) low-pressure polypropylene bag;

[0028] S104: Autoclaving the bag material of S103, using the PDA medium to make the mother seed of the edible fungus bag material, and aseptically inoculating the mother seed culture material ...

example 1

[0032] (1) Sawdust

[0033] 1 formula: vermicompost 25%, bran 13%, sawdust 58%, sucrose 1%, corn pistil powder 2%, gypsum powder 1%;

[0034] 2 formula vermicompost 25% bran 13% sawdust 65% soybean flour 1% sucrose 1% gypsum powder 1%;

[0035] (2) Cottonseed hulls

[0036] 1 Cottonseed hull 78%, vermicompost 20%, sucrose 1%, gypsum powder 1%

[0037] 2 Cottonseed hulls 64%, vermicompost 25%, bran 8%, sucrose 1%, gypsum powder 1%, soybean meal 0.5%, phosphate fertilizer 0.5%

[0038] (3) Bagasse

[0039] 1 Bagasse 67%, vermicompost 25%, bran (or rice bran) 5%, sucrose 1%, gypsum powder 1%, urea 0.5%, superphosphate 0.5%

[0040] 2 Bagasse 68%, vermicompost 20%, bran (or rice bran) 5%, gypsum powder 1%, soybean powder 1%

[0041] (4) Corn cobs

[0042] 1 Corn cob 68%, vermicompost 25%, bran (or rice bran) 5%, sucrose 1%, gypsum powder 1%

[0043] 2 Corn cob 78%, vermicompost 20%, bran (or rice bran) 15%, sucrose 1%, gypsum powder 1%, superphosphate 0.5%

[0044] (5) Str...

Embodiment 2

[0056]Formula Vermicompost 33%, Bran 8%, Sawdust 59%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com