Zirconium oxide-corundum composite ceramic body for cement grinding mill and production process of zirconium oxide-corundum composite ceramic body

A technology of composite ceramics and production technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of low grinding efficiency, high cost, and high wear of glass balls, and achieve light weight, long replacement cycle, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

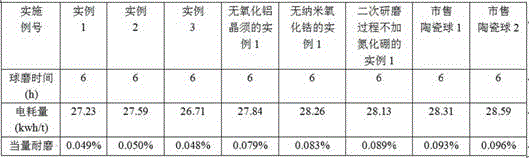

Examples

Embodiment 1

[0050] The parts by weight and the addition ratio of the raw materials of the zirconia-corundum composite ceramic body are: 97 parts of alumina micropowder with a particle size of 0.1 μm, 0.1-0.5 parts of alumina whiskers with an average diameter of 0.5 μm and an average length of 8 μm Parts, 0.4-2.5 parts of nano-zirconia with a particle size of 4nm, talc and Y 2 o 3 0.05-0.1 parts (talc: Y 2 o 3 =1:1).

[0051] First, 97 parts of alumina fine powder with a particle size of 0.1 μm, 0.1-0.5 parts of alumina whiskers with an average diameter of 0.5 μm and an average length of 8 μm, and 0.4-2.5 parts of nano-zirconia with a particle size of 4 nm, Talc and Y 2 o 3 0.05-0.1 parts (talc: Y 2 o 3 =1:1) Put it into the ball mill, add water for wet grinding, run for 30-45 hours, sieve the mill through 0.063mm, put it into the mud pool, stir and stale for 36-50h, and then remove iron to get a slurry with a water content of 60% , and then input into the spray drying tower for sp...

Embodiment 2

[0053] The parts by weight and the addition ratio of the raw materials of the zirconia-corundum composite ceramic body are: 99 parts of alumina micropowder with a particle size of 2 μm, 0.3 parts of alumina whiskers with an average diameter of 2 μm and an average length of 100 μm. 0.6 parts of 60nm nano zirconia, Y 2 o 3 0.1 part.

[0054] First, 99 parts of alumina micropowder with a particle size of 2 μm, 0.3 parts of alumina whiskers with an average diameter of 2 μm and an average length of 100 μm, and 0.6 parts of nano-zirconia with a particle size of 60 nm, Y 2 o 3 Put 0.1 part into the ball mill, add water for wet milling, run for 30-45 hours, sift out the mill through 0.063mm, put it into the mud pool and stir for 36 hours, then remove iron to get a slurry with a water content of 60%, and then input it into spray drying The powder is sprayed in the tower, and the dried powder is transported to the large silo to stale for 2-4 days to obtain a powder with a water conte...

Embodiment 3

[0056] The parts by weight and the addition ratio of the raw materials of the zirconia-corundum composite ceramic body are: 98 parts of alumina micropowder with a particle size of 1 μm, 0.1 part of alumina whiskers with an average diameter of 1 μm and an average length of 60 μm, and a particle size of 1 μm. 1.8 parts of 10nm nano zirconia, SiO 2 , CaO, MgO0.1 part (SiO 2 : CaO: MgO =1:1:2).

[0057] First put the above ingredients into the ball mill, add water for wet milling, run for 40 hours, pass through a 0.063mm sieve, put the mill into the mud pool and stir for 50 hours, then remove iron to obtain a slurry with a water content of 60%, and then input it into spray drying The powder is sprayed in the tower, and the dried powder is transported to the large silo to stale for 4 days to obtain a powder with a water content of 2%. The powder is formed into a billet by extrusion molding to obtain a spherical shape with a water content of 1%. Green body: place the spherical gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com