A kind of negative thermal expansion material sc2w4o15 and its solid phase sintering synthesis method

A technology of negative thermal expansion material and synthesis method, which is applied in the directions of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of restricted application and easy decomposition, and achieve the effects of short reaction time, fast sintering speed and sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Negative thermal expansion material Sc 2 W 4 o 15 The solid phase sintering synthesis method, the steps are as follows:

[0030] (1) Analytical pure powder reagent Sc 2 o 3 、WO 3 Massive Sc 2 o 3 : WO 3 =1:4 weighed, mixed evenly in an agate mortar, added wetting equivalent absolute ethanol, and ground for 2 h;

[0031] (2) Using a single-axis dry powder tablet press under the condition of a pressure of 8 Mpa, the uniformly ground mixture in step (1) was pressed into tablets to make embryos, with a diameter of 10 mm and a thickness of 3 mm;

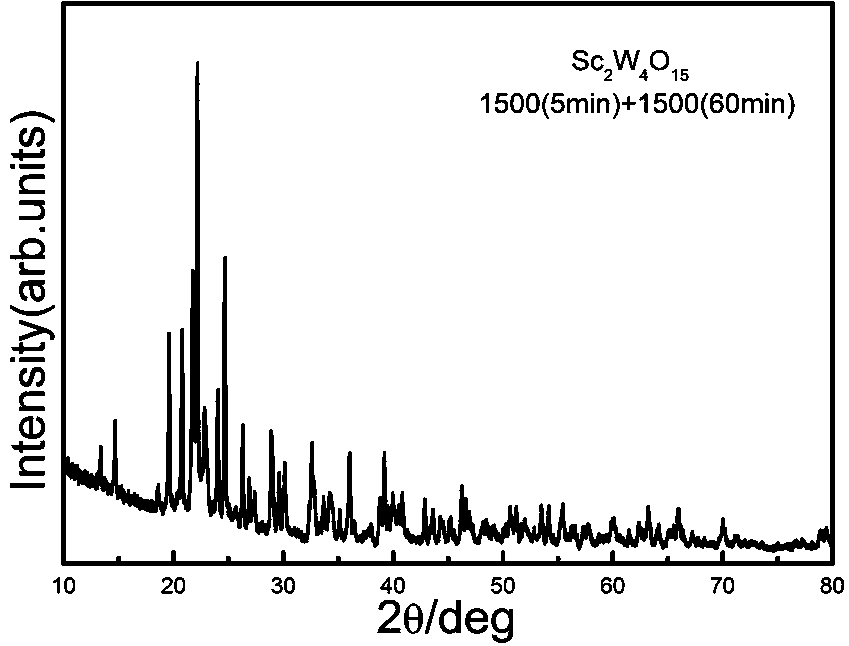

[0032] (3) Set the furnace temperature of the high-temperature tube furnace to 1500 °C. After the temperature in the high-temperature tube furnace reaches the preset temperature and stabilizes, put the corundum crucible with the sample embryo into the tube furnace, and put it in the atmospheric air atmosphere Sinter at 1500°C for 5 minutes for the first time, quickly take it out, quench it in deionized water at room tempe...

Embodiment 2

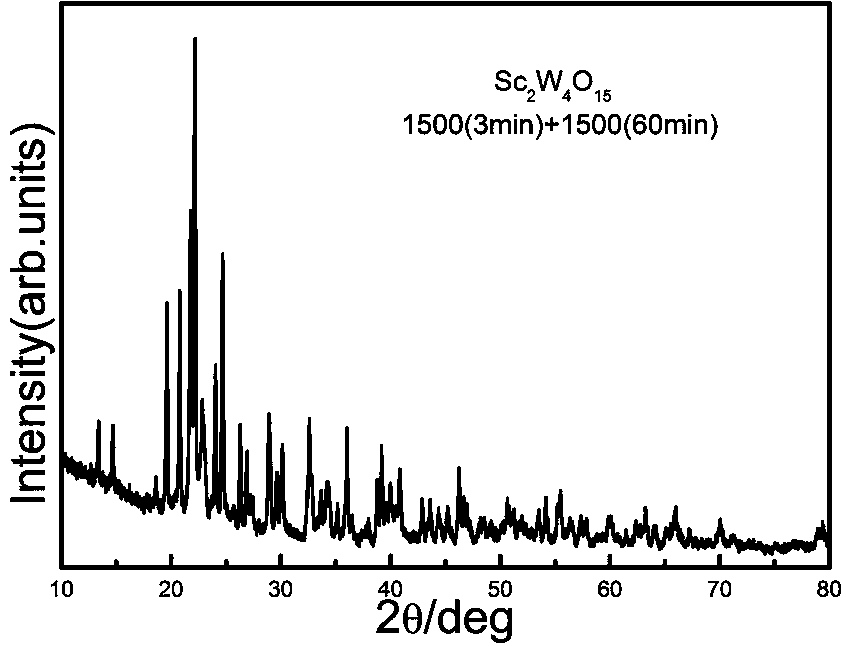

[0036] The difference from Example 1 is that in step (3), the first sintering is 3 min.

[0037] For the corresponding XRD pattern of the product, see figure 2 , figure 2 There are no raw material peaks and possible intermediate product peaks in the given XRD pattern, indicating that the prepared product is pure orthorhombic phase structure Sc 2 W 4 o 15 .

Embodiment 3

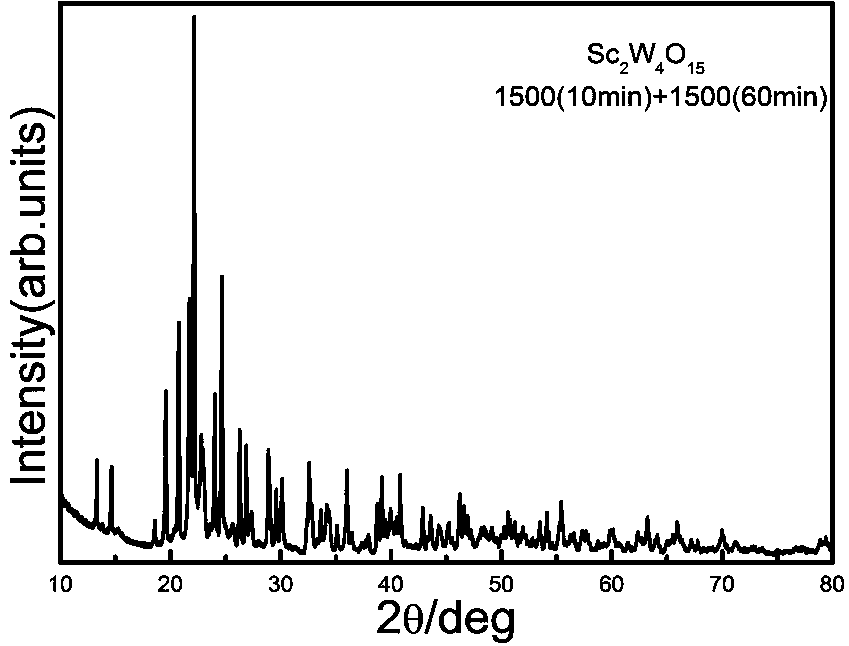

[0039] The difference from Example 1 is that in step (3), the first sintering is 10 min.

[0040] For the corresponding XRD pattern of the product, see image 3 , image 3 There are no raw material peaks and possible intermediate product peaks in the given XRD pattern, indicating that the prepared product is pure orthorhombic phase structure Sc2 W 4 o 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com