Negative thermal expansion ceramic material Fe2-xScxMo3O12 and preparation method thereof

A fe2-xscxmo3o12, ceramic material technology, applied in the field of negative thermal expansion ceramic material Fe2-xScxMo3O12 and its preparation, can solve the problems of unfavorable application, etc., and achieve the effect of low cost, good negative thermal expansion performance, and compact ceramic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Synthesis of Fe 0.6 sc 1.4 Mo 3 o 12 The raw material is analytically pure Sc 2 o 3 , Fe 2 o 3 、MoO 3 Powder, weighed Sc according to a stoichiometric ratio of 0.7:0.3:3 2 o 3 , Fe 2 o 3 and MoO 3 , mixed in water and then ball milled for 3 hours, the ball milled mixed raw materials were dried in an oven at 100°C, then ground with an agate mortar for 1 hour, and pre-fired at 750°C for 7 hours.

[0024] (2) Grind the pre-fired powder in step (1) with an agate mortar for 40 minutes, add polyvinyl alcohol accounting for 1% of the total mass of the precursor, grind it for 30 minutes to make it evenly mixed, and then cold press it at 20 MPa to form a tablet .

[0025] (3) Place the material after tableting in step (2) in the furnace for debinding at 550°C for 2 hours, sinter at 900°C for 12 hours, and obtain the negative thermal expansion ceramic material Fe after cooling in the furnace. 0.6 sc 1.4 Mo 3 o 12 .

Embodiment 2

[0027] (1) Synthesis of Fe 0.5 sc 1.5 Mo 3 o 12 The raw material is analytically pure Sc 2 o 3 , Fe 2 o 3 、MoO 3 Powder, weighed Sc according to a stoichiometric ratio of 0.75:0.25:3 2 o 3 , Fe 2 o 3 and MoO 3 , mixed in water and then ball milled for 6 hours, the ball milled mixed raw materials were dried in an oven at 110°C, then ground with an agate mortar for 0.6h, and pre-fired at 730°C for 9 hours.

[0028] (2) Grind the pre-calcined powder in step (1) for 35 minutes with an agate mortar, add polyvinyl alcohol accounting for 2% of the total mass of the precursor, grind for 25 minutes to make it evenly mixed, and then cold press it at 25 MPa to form a tablet .

[0029] (3) Place the material after tableting in step (2) in the furnace for debinding at 550°C for 2.5 hours, sinter at 830°C for 18 hours, and obtain the negative thermal expansion ceramic material Fe after cooling in the furnace. 0.5 sc 1.5 Mo 3 o 12 .

Embodiment 3

[0031] (1) Synthesis of Fe 0.4 sc 1.6 Mo 3 o 12 The raw material is analytically pure Sc 2 o 3 , Fe 2 o 3 、MoO 3 Powder, weighed Sc according to a stoichiometric ratio of 0.8:0.2:3 2 o 3 , Fe 2 o 3 and MoO 3 , mixed in water and then ball milled for 9 hours, the ball milled mixed raw materials were dried in an oven at 120°C, then ground with an agate mortar for 0.5h, and pre-fired at 700°C for 12 hours.

[0032] (2) Grind the pre-fired powder in step (1) with an agate mortar for 30 minutes, add polyvinyl alcohol accounting for 3% of the total mass of the precursor, grind it for 30 minutes to make it evenly mixed, and then cold press it at 30 MPa to form a tablet .

[0033] (3) Place the material after tableting in step (2) in the furnace for debinding at 550°C for 3 hours, sinter at 780°C for 24 hours, and obtain negative thermal expansion ceramic material Fe0.4Sc1.6Mo3O12 after cooling in the furnace.

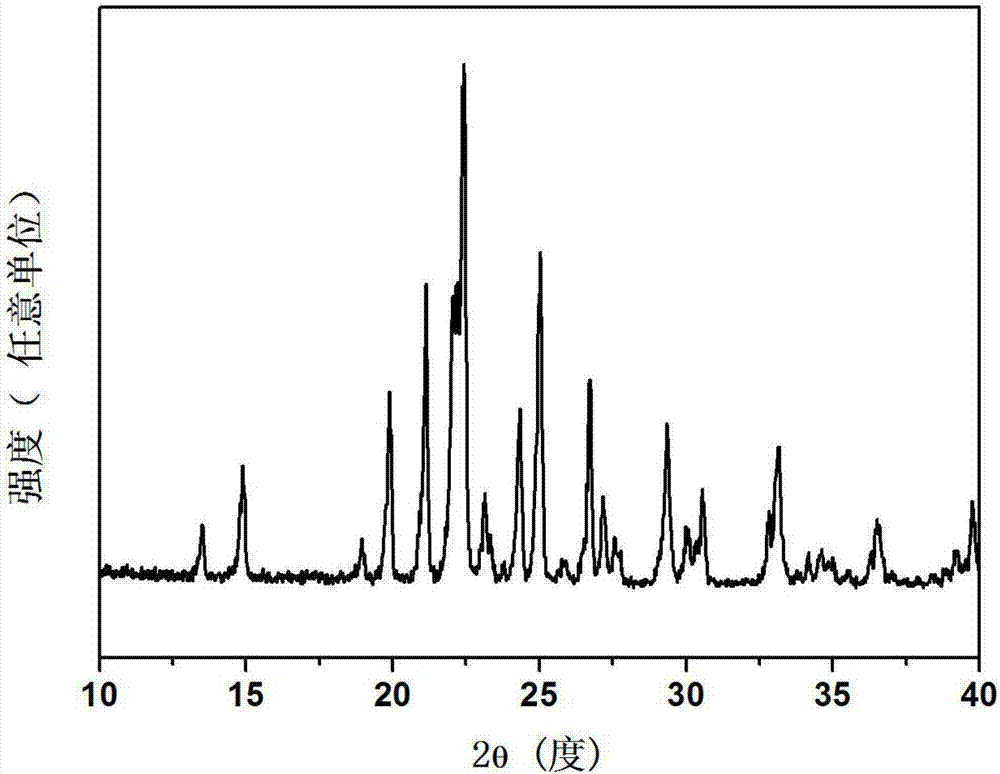

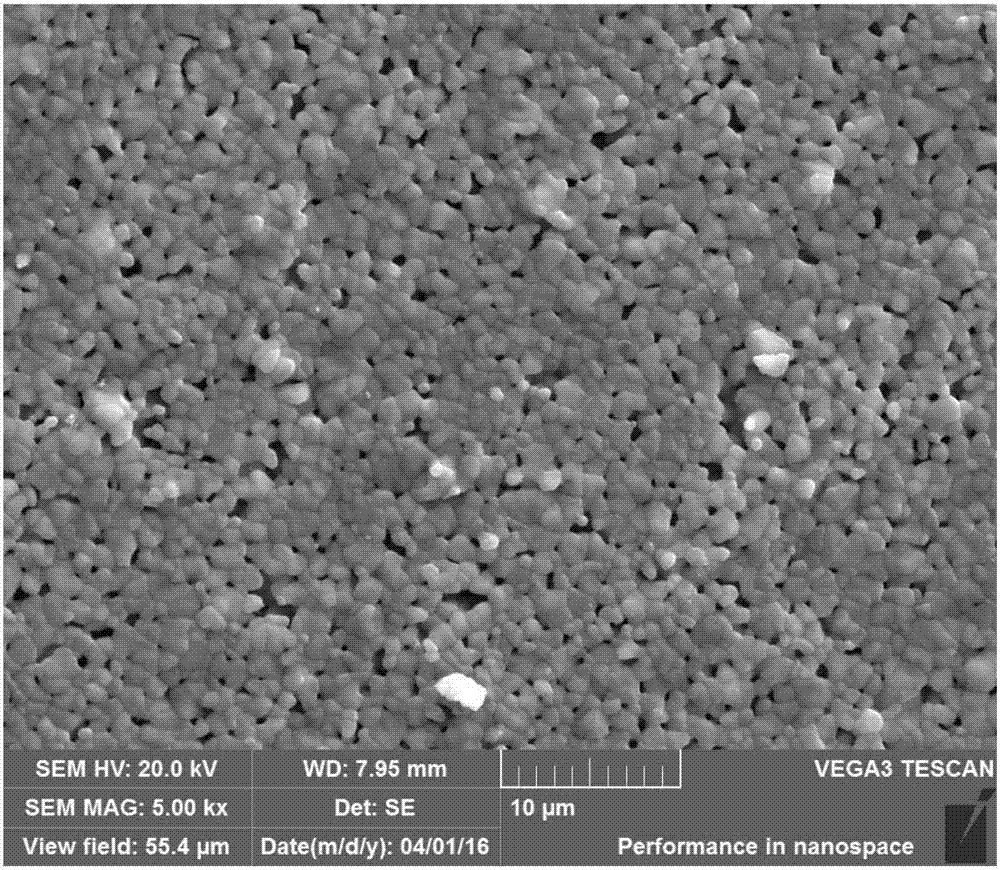

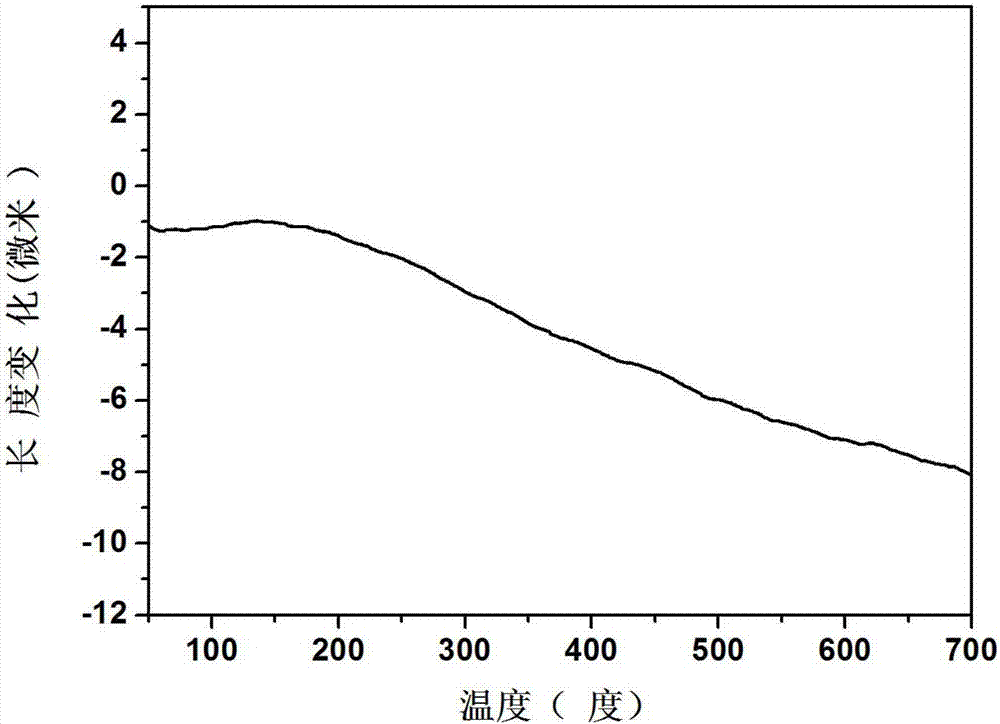

[0034] Down figure 1 It is the XRD spectrum of the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com