Method for preparing NaA molecular sieve membrane by inner surface of asymmetric micro-pore ceramic

A technology of microporous ceramics and molecular sieves, which is applied in the field of preparing NaA molecular sieve membranes on the inner surface of asymmetric microporous ceramics. Low osmotic resistance, the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

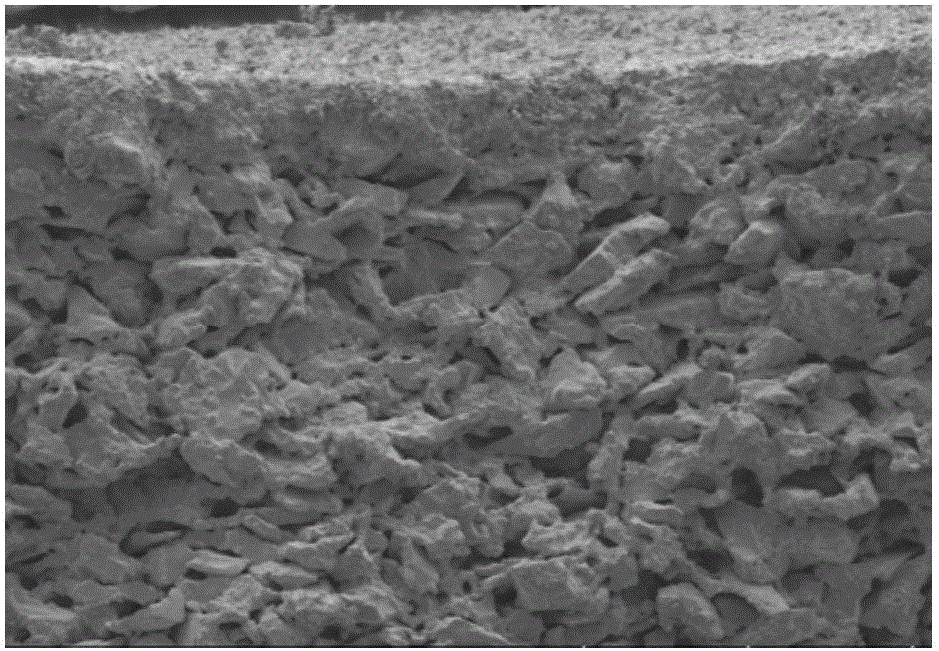

[0037] (1) Take D50=40 micron and D50=5 micron polyhedral alumina, the masses of which are respectively 75% and 25% of the total mass of polyhedral alumina. Add polyethylene glycol 600 of 2% of the total mass of polyhedral alumina as a dispersant, place it in a container for ball milling and disperse for 1 hour, then add methyl cellulose with 3% of the mass of polyhedral alumina, mix evenly with alumina, add Water with a mass of 25% polyhedral alumina and glycerin with a mass of polyhedral alumina of 1.5% are stirred into a slurry and then vacuum-extruded to form single-channel, four-channel, and seven-channel alumina support body green bodies. The green body moisture is dried and the It is sintered to 1650° C. and kept for 2 hours to obtain an asymmetric microporous ceramic matrix. The SEM image of the surface of the asymmetric microporous ceramic substrate is shown in figure 1 .

[0038] (2) Pour alumina with a median particle size of D50=2 microns into water, the mass of ...

Embodiment 2

[0041] (1) Take D50=45 micron and D50=8 micron polyhedral alumina, the masses of which are respectively 70% and 30% of the total mass of polyhedral alumina. Add polyethylene glycol 600 of 3% of the total mass of polyhedral alumina as a dispersant, place it in a container for ball milling and disperse for 1 hour, then add methyl cellulose with 5% of the mass of polyhedral alumina, mix evenly with alumina, add Water with a mass of 30% of polyhedral alumina and glycerin with a mass of polyhedral alumina of 2% are mixed into sludge and then vacuum-extruded to form single-channel, four-channel, and seven-channel alumina support body green bodies, and the green body moisture is dried. It is sintered to 1630° C. and kept for 2 hours to obtain an asymmetric microporous ceramic matrix.

[0042] (2) Pour zirconia with a median particle diameter of D50=3 microns into water, the mass of which is 6% of the mass of water, and stir evenly. Then add 4% polyethylene glycol 400 of zirconia mas...

Embodiment 3

[0045] (1) Take D50=50 micron and D50=5 micron polyhedral alumina, the masses of which are respectively 80% and 20% of the total mass of polyhedral alumina. Add polyethylene glycol 600 of 5% of the total mass of polyhedral alumina as a dispersant, place it in a container for ball milling and disperse for 1 hour, then add methyl cellulose with 6% of the mass of polyhedral alumina, mix evenly with alumina, add Water with a mass of 35% of polyhedral alumina and glycerin with a mass of polyhedral alumina of 3% are mixed into sludge and then vacuum-extruded to form single-channel, four-channel, and seven-channel alumina support body green bodies, and the green body moisture is dried. It is sintered to 1650° C. and kept for 2 hours to obtain an asymmetric microporous ceramic matrix.

[0046] (2) Pour zirconia with a median particle diameter D50=5 microns into water, the mass of which is 7% of the mass of water, and stir evenly. Then add 5% polyethylene glycol 400 of zirconia mass, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com