High-strength concrete adapting to humid environment and preparation method

A high-strength concrete and wet environment technology, applied in the field of high-strength concrete, can solve problems such as reducing the mechanical properties and durability of concrete, damage to high-strength concrete structures, and multiple micro-cracks in concrete, so as to reduce the risk of cracking, improve impermeability, and shrinkage deformation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

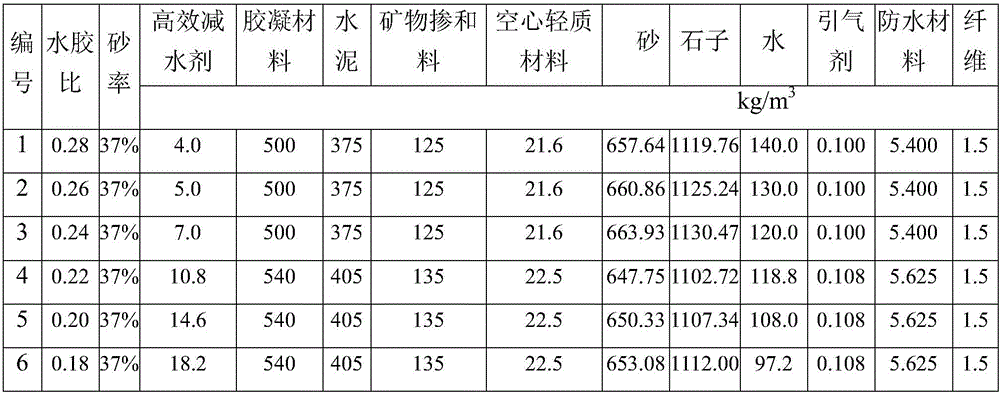

[0028] Embodiment 1, embodiment 2, embodiment 3, embodiment 4, embodiment 5, embodiment 6 see appendix figure 1 Concrete mix design.

[0029] The main mechanical properties tested are as follows:

[0030] High-strength concrete with excellent long-term performance in humid environment has a 28-day compressive strength of 80MPa to 120MPa. According to the cracking test conducted according to the national standard, no cracks appeared within 48 hours, and the crack resistance is good.

[0031] The present invention proposes that the mix ratio of high-strength concrete is only a case, which can be changed according to actual needs but must be within the design range. Due to the complex interaction between various raw materials in high-strength concrete, excessive changes will cause cracks in the early stage of high-strength concrete or decline in strength and durability in the later stage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com