Low-fluorine phosphate frequency-doubled laser color separation glass and preparation method thereof

A phosphate and frequency doubling technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of difficult preparation of large-size, high-optical-quality optical elements, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

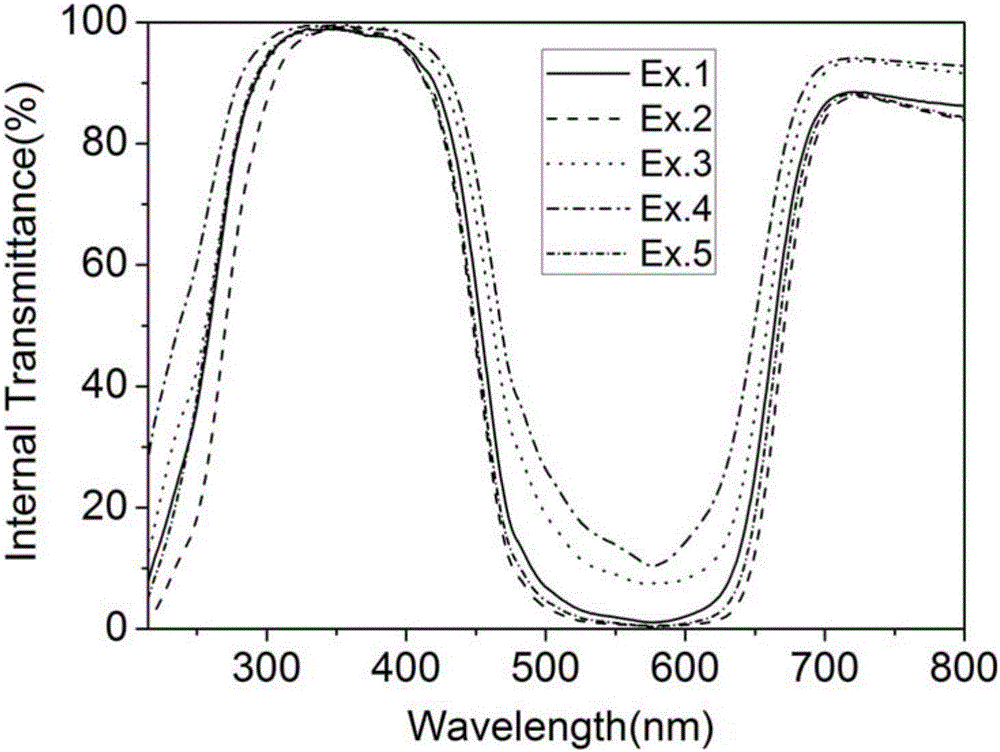

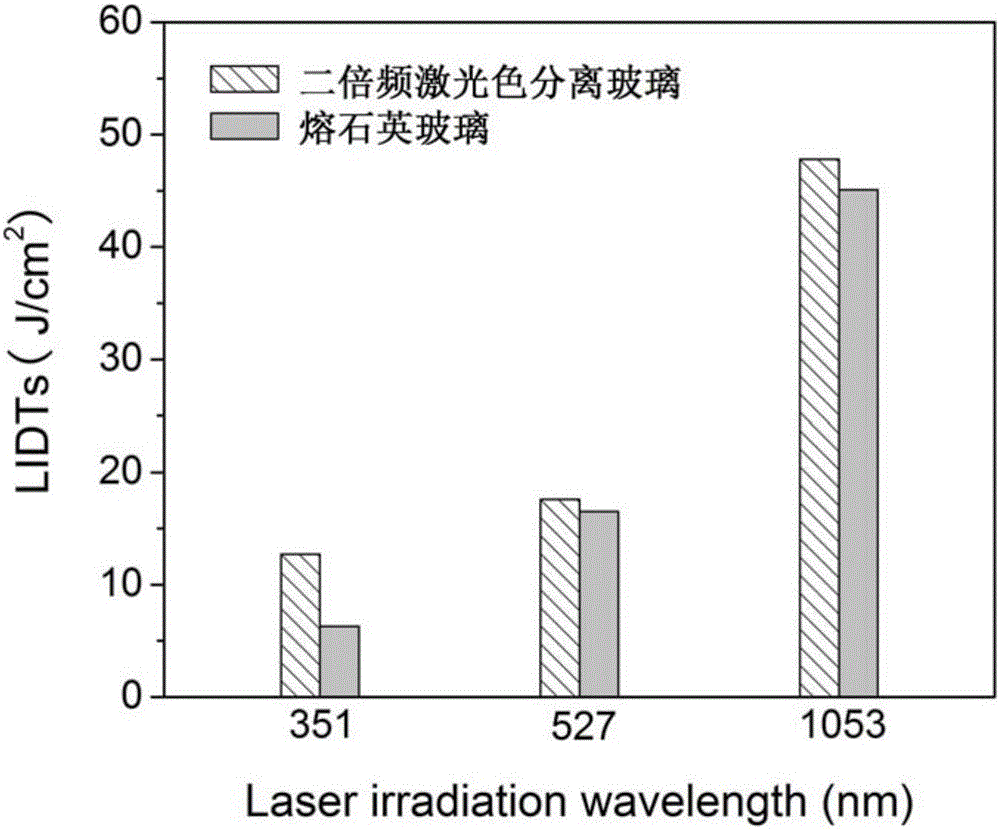

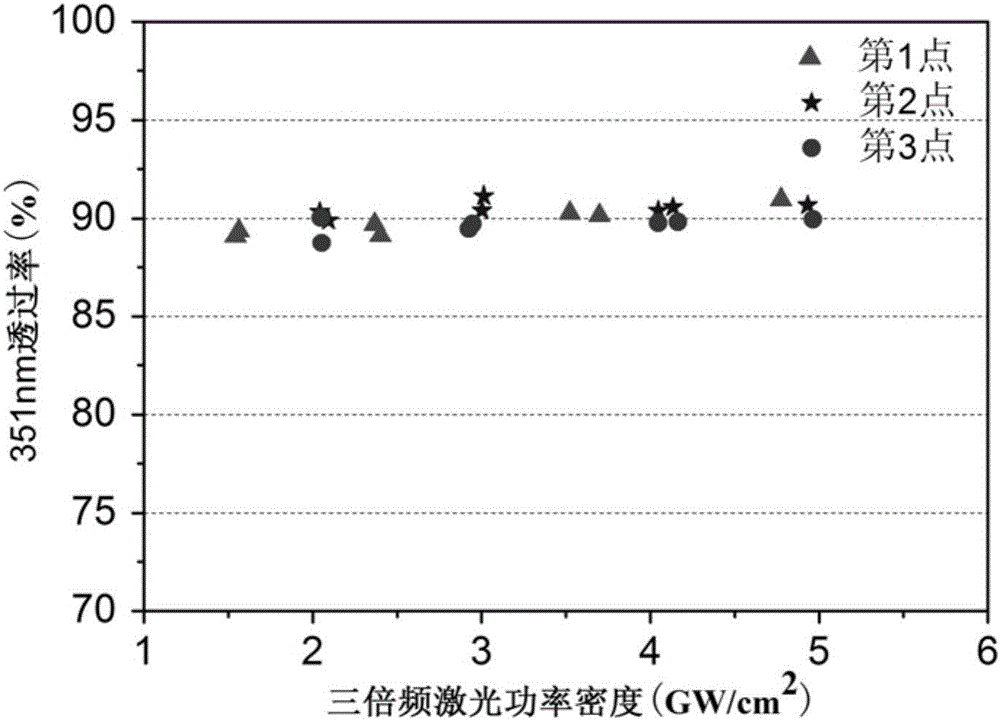

[0041] The present invention obtains a new type of large-scale UV-transparent, high-damage glass by introducing a rare earth fluoride component that can improve its UV transmission characteristics and glass-forming properties, and zinc oxide that can adjust the glass viscosity into the multi-component phosphate glass system. Low-threshold fluorine-containing phosphate double-frequency laser color separation glass material. Its preparation method is: mainly composed of alkali metal oxides, alkaline earth metal oxides, aluminum oxide, zinc oxide and phosphorus pentoxide, adding a small amount of rare earth fluoride, controlling the double frequency absorption ion valence state and glass valence through reducing atmosphere Ultraviolet absorption edge, after high temperature melting, clarification and homogenization, the glass blank is prepared by leakage casting method, and then annealed to obtain high damage threshold and low fluorine-containing phosphate laser glass material. S...

Embodiment 1

[0060] Formulation 1 according to Table 1 # Calculate the weight percent of the glass from the molar composition in the glass, then weigh a total of 25Kg of raw materials, and mix them uniformly in the mixing box. Add the prepared powder into a 13-liter crucible one by one, heat and melt through a silicon carbide electric melting furnace, control the melting temperature at about 1280 ° C, and the melting time is 6 to 8 hours. The liquid is stirred. During the high-temperature clarification process of molten glass, H is introduced into the crucible 2 or H 2 with N 2 The mixed gas creates a reducing atmosphere, controls the valence state of absorbed ions, and reduces the ultraviolet absorption caused by impurity ions. After the glass liquid has been clarified to remove air bubbles and fully stirred evenly, the high-temperature glass liquid is injected into the copper mold preheated to 300°C through the leak nozzle at the bottom of the crucible to form a glass blank, and the ...

Embodiment 2

[0065] Formulation 2 according to Table 1 # Calculate the weight percent of the glass from the molar composition in the glass, then weigh a total of 25Kg of raw materials, and mix them uniformly in the mixing box. Add the prepared powder into a 13-liter crucible one by one, heat and melt through a silicon carbide electric melting furnace, control the melting temperature at about 1280 ° C, and the melting time is 6 to 8 hours. The liquid is stirred. During the high-temperature clarification process of molten glass, H is introduced into the crucible 2 or H 2 with N 2 The mixed gas creates a reducing atmosphere, controls the valence state of absorbed ions, and reduces the ultraviolet absorption caused by impurity ions. After the glass liquid has been clarified to remove air bubbles and fully stirred evenly, the high-temperature glass liquid is injected into the copper mold preheated to 290°C through the leak nozzle at the bottom of the crucible to form a glass blank, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Nonlinear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com