Method for preparing high-damage-threshold laser window material

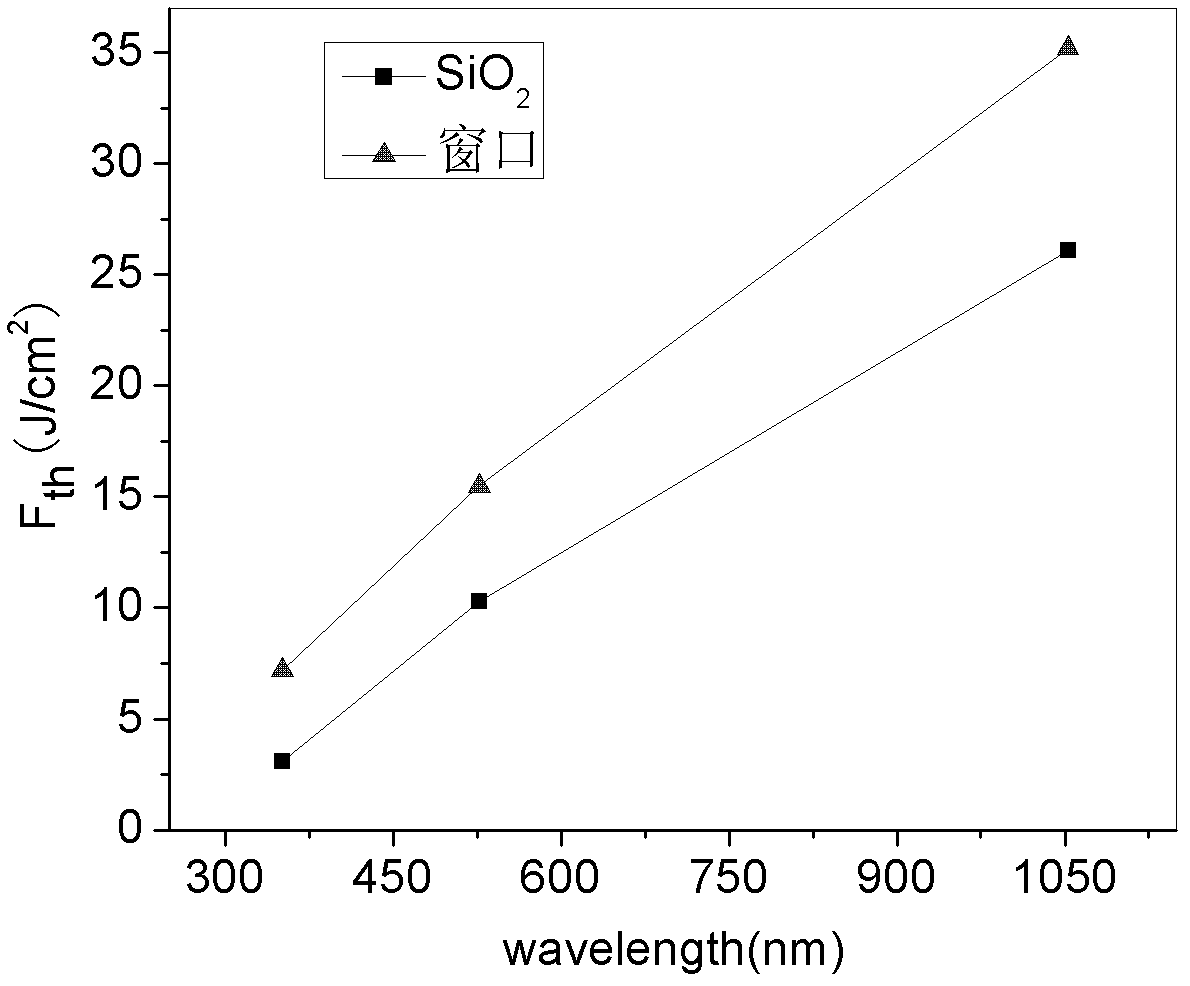

A high damage threshold and laser window technology, applied in the field of optical materials, can solve the problems of easy crystallization of fluoride glass, difficulty in large-scale production, low triple frequency damage threshold, etc., and achieve the effect of increasing damage threshold and improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

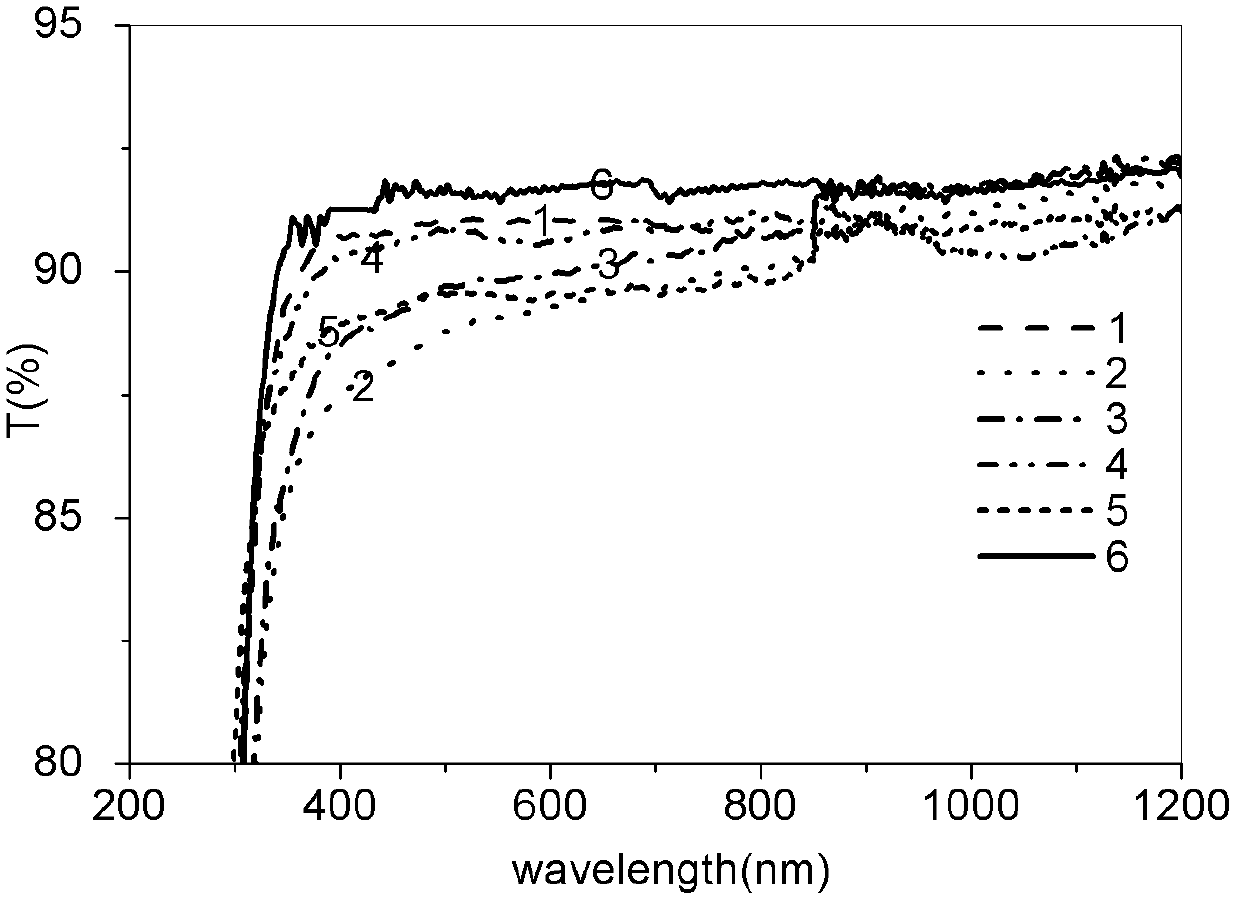

Examples

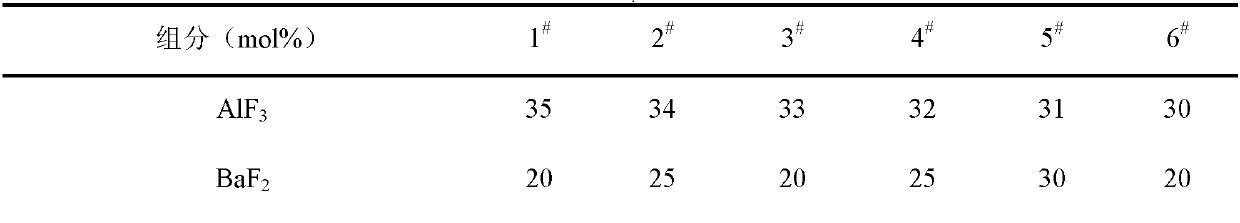

Embodiment 1

[0033] According to the above recipe 1 # Calculate the weight percent of the glass from the molar composition in the glass, and then weigh 10Kg of raw materials and mix them evenly. Add the prepared powder into the crucible one by one, heat and melt through the electric melting furnace, the melting temperature is controlled at about 1200°C, the melting time is 24 hours, and the glass liquid is stirred during the melting process. After the molten glass is clarified, inject the molten glass into the preheated mold, and quickly put the glass into the muffle furnace that has been heated up. First, keep it warm at the transition temperature Tg of the glass for 2 hours, and then heat it at 10°C / hour. Anneal at a speed of 50°C, close the muffle furnace, cool down to room temperature, and finally take out the finished product.

[0034] Take 10 mg of the annealed sample, grind it into a very fine powder with an agate bowl, and conduct differential thermal analysis. T of the tested sa...

Embodiment 2

[0037] According to the above recipe 2 # Calculate the weight percent of the glass from the molar composition in the glass, and then weigh 10Kg of raw materials and mix them evenly. Add the prepared powder into the crucible one by one, heat and melt through the electric melting furnace, the melting temperature is controlled at about 1200°C, the melting time is 24 hours, and the glass liquid is stirred during the melting process. After the molten glass is clarified, inject the molten glass into the preheated mold, and quickly put the glass into the muffle furnace that has been heated up. First, keep it warm at the transition temperature Tg of the glass for 2 hours, and then heat it at 10°C / hour. Anneal at a speed of 50°C, close the muffle furnace, cool down to room temperature, and finally take out the finished product.

[0038] Take 10 mg of the annealed sample, grind it into a very fine powder with an agate bowl, and conduct differential thermal analysis. T of the tested sa...

Embodiment 3

[0041] According to the above recipe 3 #Calculate the weight percent of the glass from the molar composition in the glass, and then weigh 10Kg of raw materials and mix them evenly. Add the prepared powder into the crucible one by one, heat and melt through the electric melting furnace, the melting temperature is controlled at about 1200°C, the melting time is 24 hours, and the glass liquid is stirred during the melting process. After the molten glass is clarified, inject the molten glass into the preheated mold, and quickly put the glass into the muffle furnace that has been heated up. First, keep it warm at the transition temperature Tg of the glass for 2 hours, and then heat it at 10°C / hour. Anneal at a speed of 50°C, close the muffle furnace, cool down to room temperature, and finally take out the finished product.

[0042] Take 10 mg of the annealed sample, grind it into a very fine powder with an agate bowl, and conduct differential thermal analysis. T of the tested sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com