Preparation method for lithium manganese silicate/carbon composite material used as positive electrode material of lithium ion battery, and positive electrode slurry and application

A technology of carbon composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity, poor cycle performance, and poor electronic conductivity of lithium manganese silicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

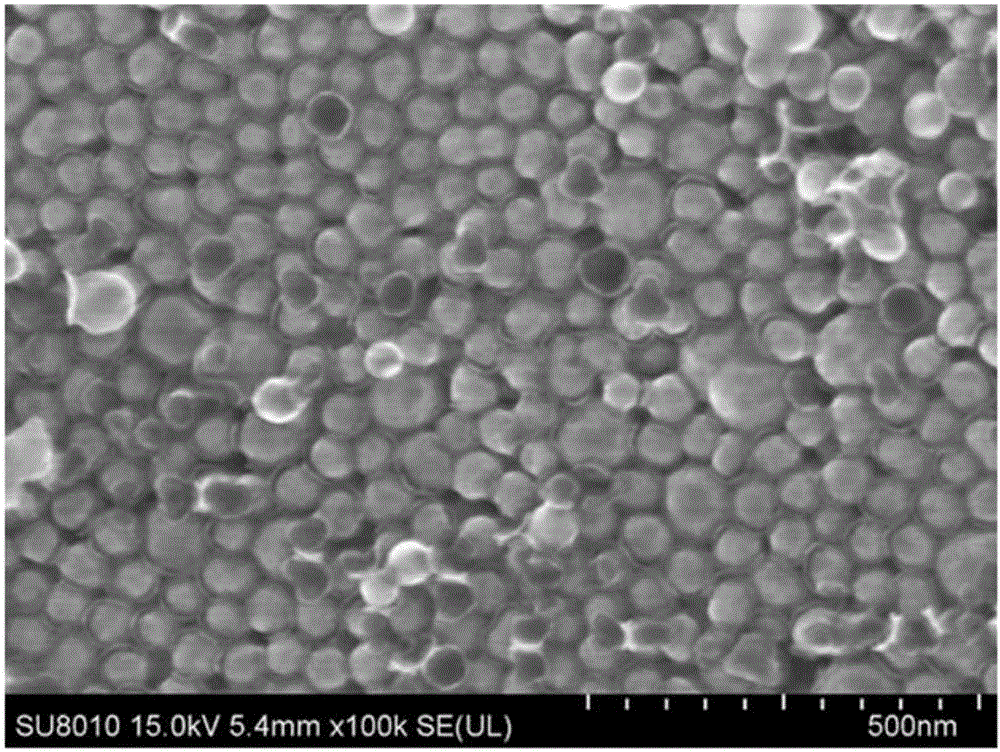

[0035] Step 1. Egg yolk-eggshell structure SiO 2 Preparation of @void@C composite materials

[0036] (1) Weigh SiO with a particle size of about 100nm 2 Add 10 g of granules to 100 g of distilled water, and add 3 g of glucose under the action of magnetic stirring. Stir for 3h to make it evenly mixed.

[0037] (2) Stir the above solution at 60°C until the solvent is completely volatilized, grind the resulting solid in an agate mortar, then transfer to a tube furnace, and calcinate at 750°C for 4h under the protection of an inert atmosphere to obtain SiO 2 @C Composite.

[0038] (3) Then weigh 10g SiO 2 The @C composite material is added to 100 ml at a concentration of 1mol L -1 The NaOH solution was reacted for 2 h under magnetic stirring, then washed with distilled water for several times and collected by centrifugation, transferred to a blast drying oven, and dried at 80°C for 3 h. Obtain yolk-eggshell structure SiO 2 @void @C composites.

[0039] Step 2, preparation...

Embodiment 2

[0044] Step 1. Egg yolk-eggshell structure SiO 2 Preparation of @void@C composite materials

[0045] (1) Weigh SiO with a particle size of about 200nm 2 Add 10 g of granules to 100 g of distilled water, and add 2 g of glucose under the action of magnetic stirring. Stir for 3h to make it evenly mixed. The above solution was stirred at 60°C until the solvent was completely evaporated, the resulting solid was ground in an agate mortar, then transferred to a tube furnace, and calcined at 750°C for 4 h under the protection of an inert atmosphere to obtain SiO 2 @C Composite.

[0046] (2) Then weigh 10g SiO 2 The @C composite material was added to 100 ml of hydrofluoric acid solution with a mass fraction of 10%, reacted for 2 hours under magnetic stirring, then washed with distilled water several times and collected by centrifugation, transferred to a blast drying oven, and dried at 80°C for 3 hours . Obtain yolk-eggshell structure SiO 2 @void @C composites.

[0047] Step 2,...

Embodiment 3

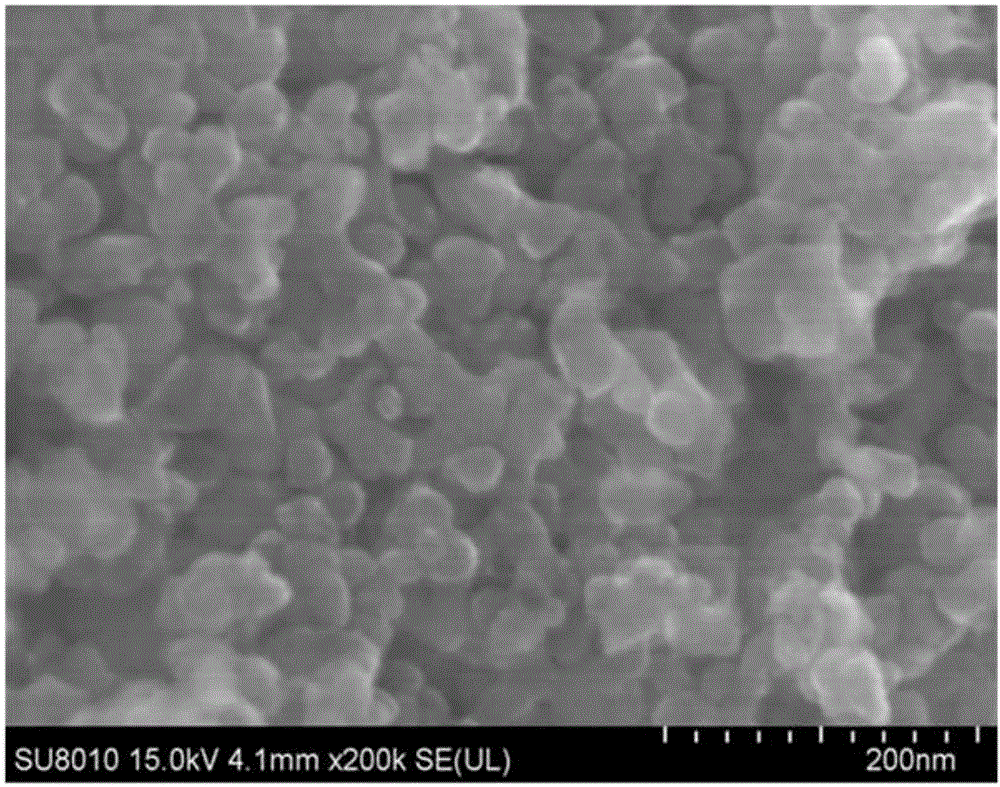

[0052] Step 1. Egg yolk-eggshell structure SiO 2 Preparation of @void@C composite materials

[0053] (1) Weigh SiO with a particle size of about 80nm 2 Add 10 g of granules to 100 g of distilled water, and add 5 g of glucose under the action of magnetic stirring. Stir for 3h to make it evenly mixed.

[0054] (2) Stir the above solution at 60°C until the solvent is completely volatilized, grind the resulting solid in an agate mortar, then transfer to a tube furnace, and calcinate at 750°C for 4h under the protection of an inert atmosphere to obtain SiO 2 @C Composite.

[0055] (3) Then weigh 10g of SiO2@C composite material and add it to 100ml with a concentration of 2mol L -1 The NaOH solution was reacted under magnetic stirring for 1 h, then washed with distilled water several times and collected by centrifugation, transferred to a blast drying oven, and dried at 80°C for 3 h. Obtain yolk-eggshell structure SiO 2 @void @C composites.

[0056] Step 2, preparation of li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com