Heterojunction solar cell device production method based on amorphous silicon thin films

A solar cell, amorphous silicon thin film technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of unsatisfactory photoelectron generation and collection capacity, high production cost of a-Si cells, unfavorable production capacity, etc. The effect of short recovery time, enhanced transmission and collection, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described in detail as follows:

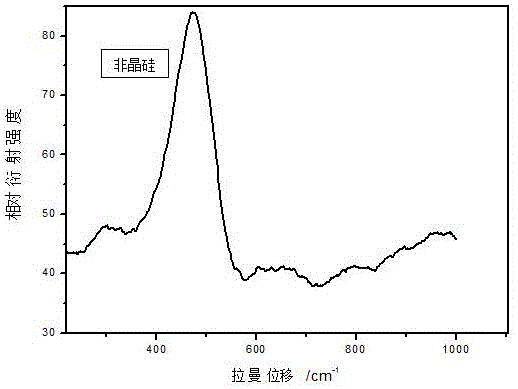

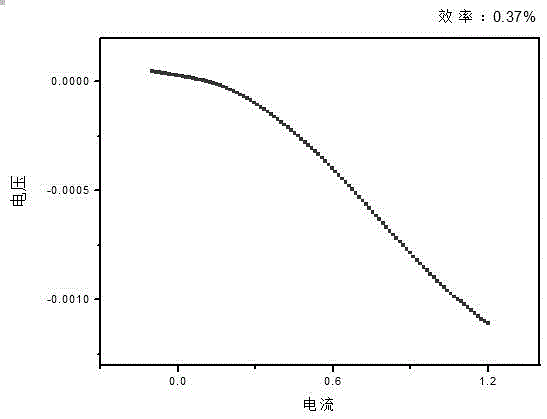

[0022] In this example, see Figure 1~3 , a method for preparing a heterojunction solar cell device based on an amorphous silicon thin film, comprising the steps of:

[0023] a. Preparation of the cathode conductive electrode layer: uniformly coat a layer of silver paste on the surface of the silicon wafer, anneal the silicon wafer in a vacuum tube furnace, the temperature range is 900 ° C, and the holding time is 10 minutes, so that the silver paste layer is cured to form a thickness 5-10 nm cathode conductive electrode layer;

[0024] b. Preparation of optical thin film amorphous silicon: use plasma enhanced chemical vapor deposition method, carry out chemical vapor deposition process according to the ratio of hydrogen, silane and borane in the ratio range of 10:80:3, control the radio frequency power range to 60W , the temperature range is 200°C, the pressure is 0.6Torr, and the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com