A chemical method for synthesizing copper-zinc iodide ternary wide bandgap compound semiconductor thin film materials

A thin film material and chemical method technology, applied in the field of material chemistry, can solve problems such as high reaction temperature, large environmental impact, and complicated operation, and achieve the effect of simple reaction device, low price, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation: Clean the ordinary glass with detergent and deionized water ultrasonically for 20 minutes, and then use concentrated ammonia water (25% by mass) / hydrogen peroxide (30% by mass) / deionized water (1:2 by volume) :5) was treated at 80°C for 30 minutes, and finally ultrasonically cleaned with deionized water for 20 minutes. The treated ordinary glass was dried at 80°C and stored in a clean desiccator for later use. A copper-zinc alloy layer with a thickness of 100nm is sputtered on an ordinary glass substrate by magnetron sputtering technology, and the thickness of the film is controlled by a film thickness monitor (FTM). The obtained ordinary glass with a copper-zinc alloy layer is stored in a desiccator for later use.

[0038] 2. Reaction steps: Place the ordinary glass sputtered with a copper-zinc alloy layer with a thickness of 100nm in a closed container filled with iodine vapor to react for 8 hours at 45°C, take out the sample and transfer it to a clean ...

Embodiment 2

[0040] 1. Preparatory work: Same as in Example 1, a copper-zinc alloy layer with a thickness of 100 nm is sputtered on a common glass substrate.

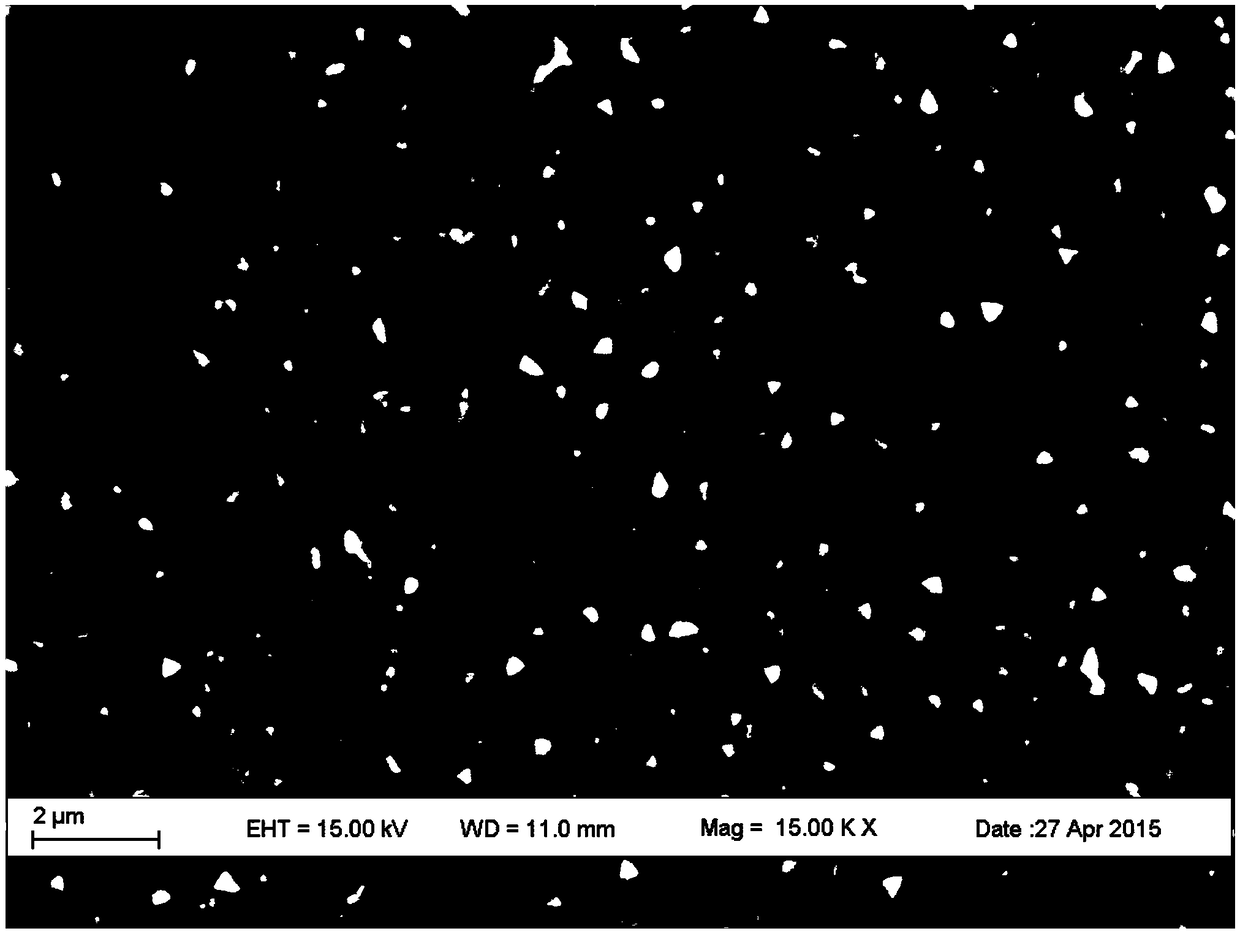

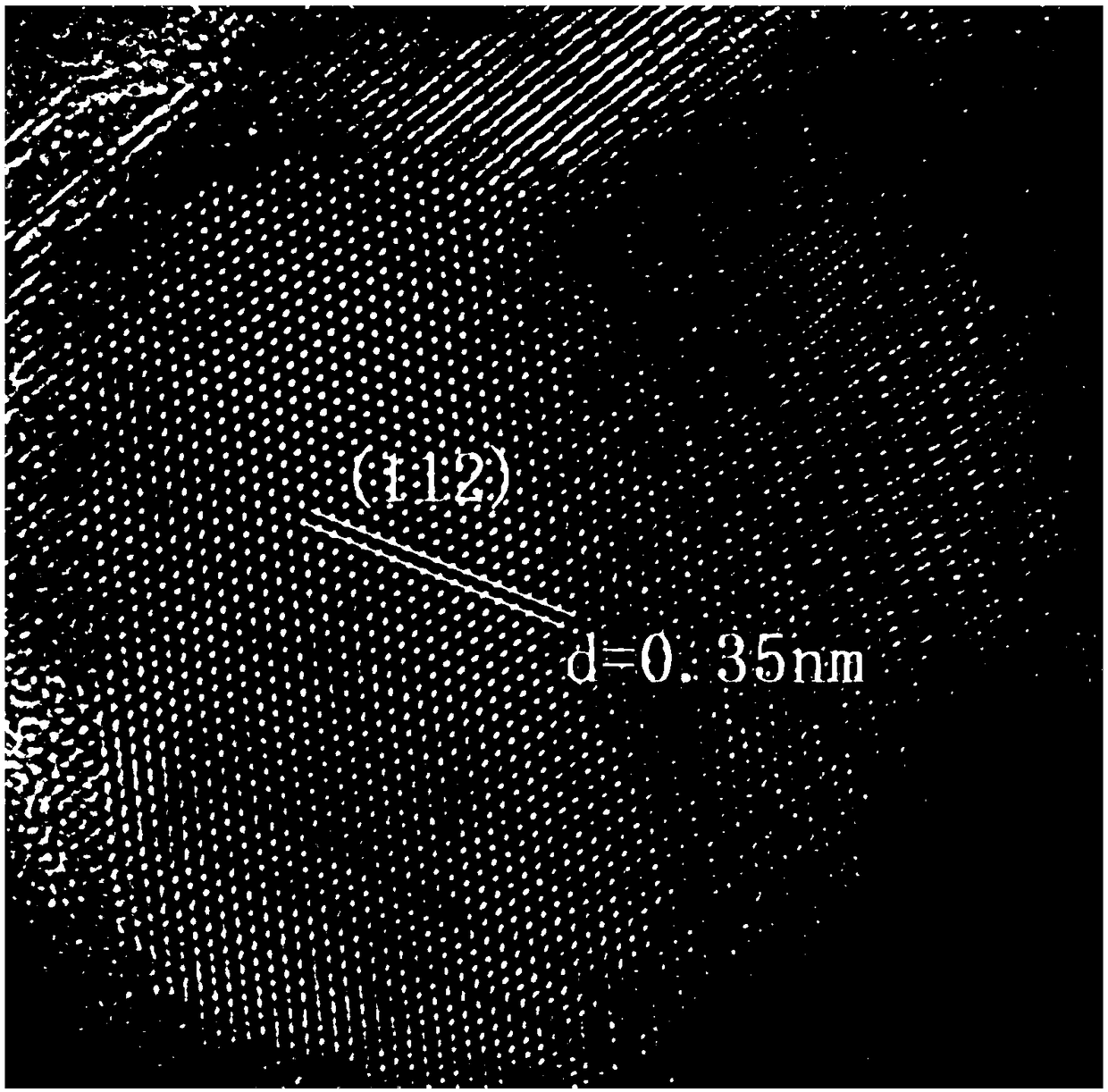

[0041] 2. Reaction steps: Place the ordinary glass sputtered with a 100nm copper-zinc alloy layer in an airtight container filled with iodine vapor to react for 5 hours at 60°C, take out the sample and transfer it to a clean sample tube to avoid light and store it dry. The product obtained was a white film. Figure 4 It is the SEM photo of the obtained sample, the surface of the film is mainly composed of flake particles; Figure 5 It is the XRD pattern of the obtained sample, and the diffraction peak shown in the figure is Cu 2 ZnI 4 The (112) and (224) crystal planes, the figure shows that it has a strong (112) crystal plane dominant orientation.

Embodiment 3

[0043] 1. Preparatory work: Same as in Example 1, a copper-zinc alloy layer with a thickness of 100 nm is sputtered on a common glass substrate.

[0044] 2. Reaction steps: Place the ordinary glass sputtered with a 100nm copper-zinc alloy layer in a closed container filled with iodine vapor to react for 3 hours at 70°C, take out the sample and transfer it to a clean sample tube to avoid light and store it dry. The product obtained was a white film. Figure 6 It is the SEM photo film of the obtained sample, the surface is mainly composed of flakes and irregular particles; Figure 7 It is the XRD pattern of the obtained sample, and the diffraction peak shown in the figure is Cu 2 ZnI 4 The (112) and (224) crystal planes, the figure shows that it has a strong (112) crystal plane dominant orientation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com