Method for direct determination of titanium carbide content in titanium carbide slag by X-ray fluorescence spectrometry

A technology of ray fluorescence spectroscopy and fluorescence spectroscopy, which is applied in the field of physical and chemical detection, can solve the problems of large influence of human factors, large fluctuations in results, and inability to meet, and achieve stable and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 X-ray fluorescence spectrometry directly measures the method for titanium carbide content in titanium carbide slag

[0051] (1) Preparation of sample (A# sample)

[0052] a Titanium carbide phase separation

[0053] Accurately weigh 0.2000g titanium carbide slag sample, add 19wt% hydrochloric acid 50mL (19wt% hydrochloric acid is used density is 1.179g / cm 3 , concentrated hydrochloric acid with a mass fraction of 36% and water at a volume ratio of 1:1), 63wt% sulfuric acid 10mL (63wt% sulfuric acid is prepared with a density of 1.84g / cm 3 , with a mass fraction of 98% concentrated sulfuric acid and water in a volume ratio of 1:1), 40wt% concentrated hydrofluoric acid 3mL, heated to boiling at low temperature, and kept boiling slightly for 22min. Cool, filter with ash-free filter paper in a 500mL Erlenmeyer flask, and wash the residue.

[0054] b residue burning

[0055] Put the washed residue together with the filter paper in a platinum yellow crucible,...

Embodiment 2

[0076] Embodiment 2 accuracy test

[0077] Since there is no standard sample for carbide slag at present, we use standard sample preparation and comparison to test the accuracy of the method.

[0078] (1) Take 4 parts of 0.1500g vanadium-titanium blast furnace slag standard sample (YSBC19815-2014), then weigh 21.1mg, 25.2mg, 30.2mg of 99% titanium carbide respectively, test the three samples according to the method of the present invention, test The results are shown in Table 2, and the test values are consistent with the theoretical values.

[0079] Table 2

[0080] serial number TiC addition amount mg Theoretical value% test value% 0 0 0 0 1 21.1 10.55 10.57 2 25.2 12.60 12.65 3 30.2 15.10 15.17

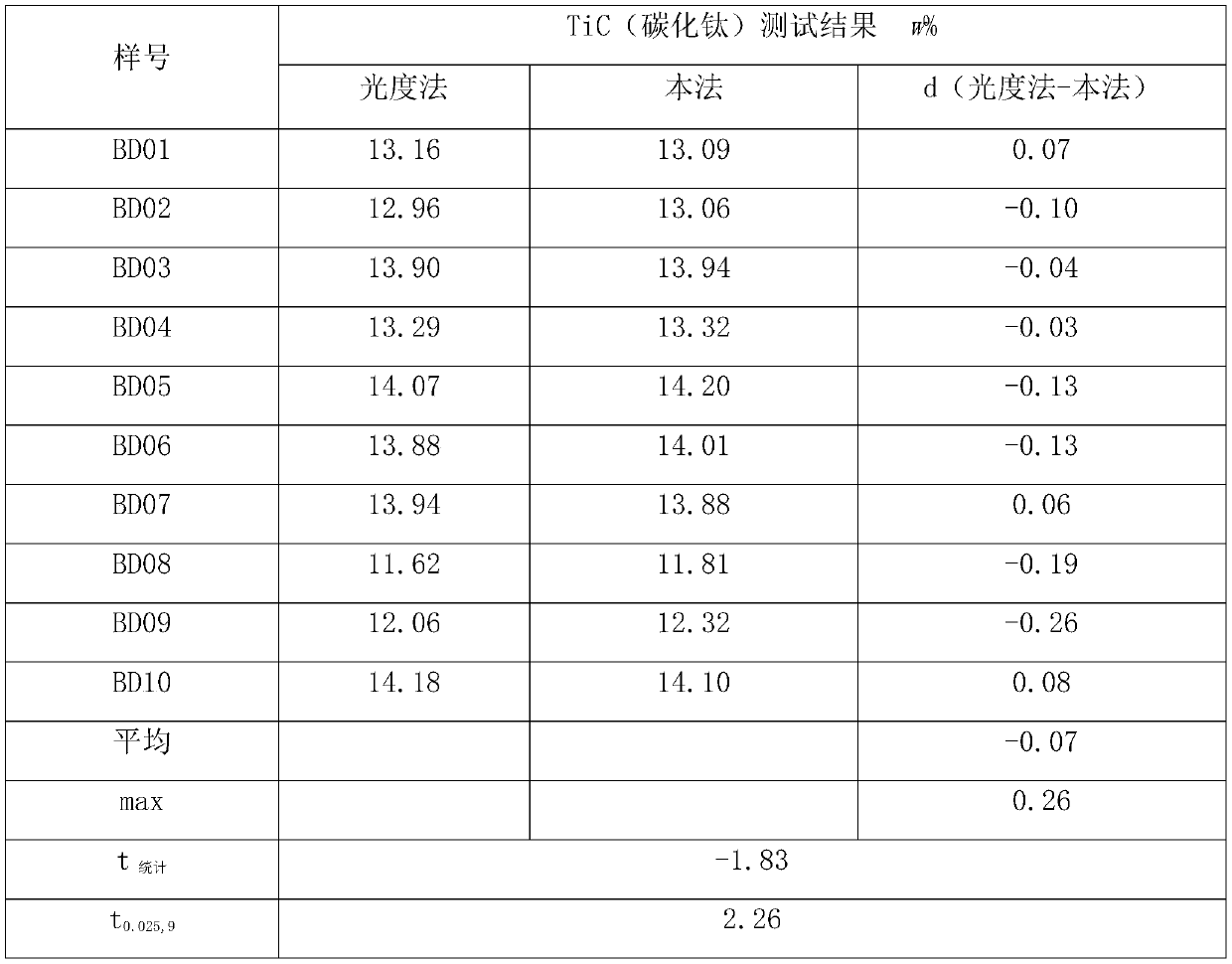

[0081] (2) Get 10 titanium carbide samples, adopt this method and chemical method (photometric method) to carry out comparison test, titanium carbide test result is as table 3, shows with paired data t test, two kinds of methods h...

Embodiment 3

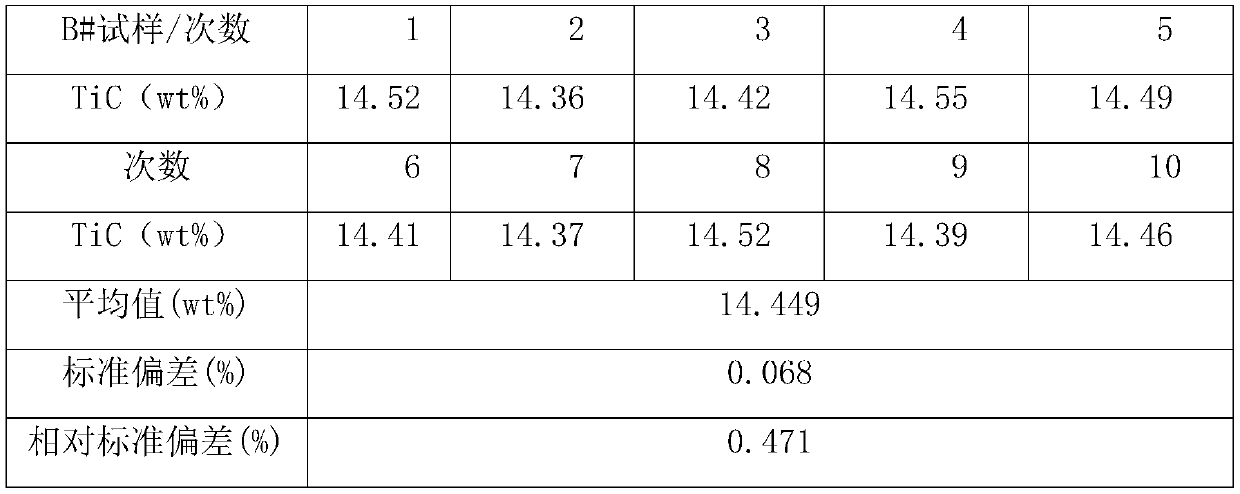

[0084] Embodiment 3 precision test

[0085] In order to verify the precision of this method, the A# and B# samples were tested 10 times (Table 4, Table 5). The stability and good reproducibility of the method were examined from the precision of the experimental data. The relative standard deviations of Table 4 and Table 5 are all within a small range, indicating that the entire operation process of the method is stable and reliable.

[0086] Table 4

[0087]

[0088] table 5

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com