On-line monitoring device for fume gas turbine moving blade scaling

A flue gas turbine and monitoring device technology, which is applied in the measurement device, sampling device, sampling and other directions, can solve the problems of increasing the overall energy consumption level of the device, affecting the safe and stable operation of the flue gas turbine, affecting the dynamic balance of the rotor, etc. Safe operation, slowing or eliminating scaling, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

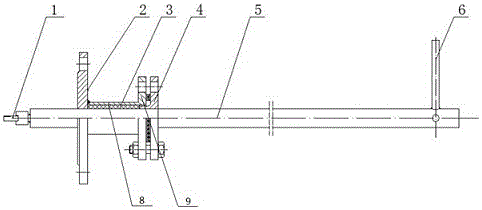

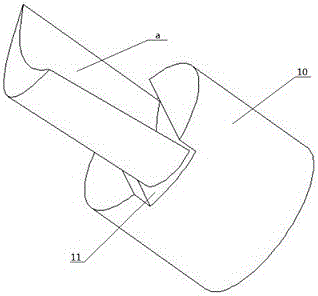

[0013] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes a sampling tube 5, a handle 6 is installed on one end of the sampling tube 5, and a stuffing tube that is socketed and matched with the other end of the sampling tube 5 is provided 8. One end of the stuffing pipe 8 is installed with a gland 4 that fits with its cover, and the other end of the stuffing pipe 8 is installed with a first flange 2 that can be connected to the flue of the flue gas turbine. The sampling pipe 5 A sampling head 1 is installed on the end surface opposite to the handle 6 .

[0014] Packing packing 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com