Continuous fiber glass fiber plate stirrup pipe composite arc-top triangular corrugated pipeline

A continuous fiber and corrugated pipeline technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, pipes, etc., can solve the problems of pipe network failure, damage, insufficient hardness and strength, etc., to improve the impact resistance of external forces, improve Stiffness, the effect of improving the resistance to lateral and vertical deformation force and resistance to external compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

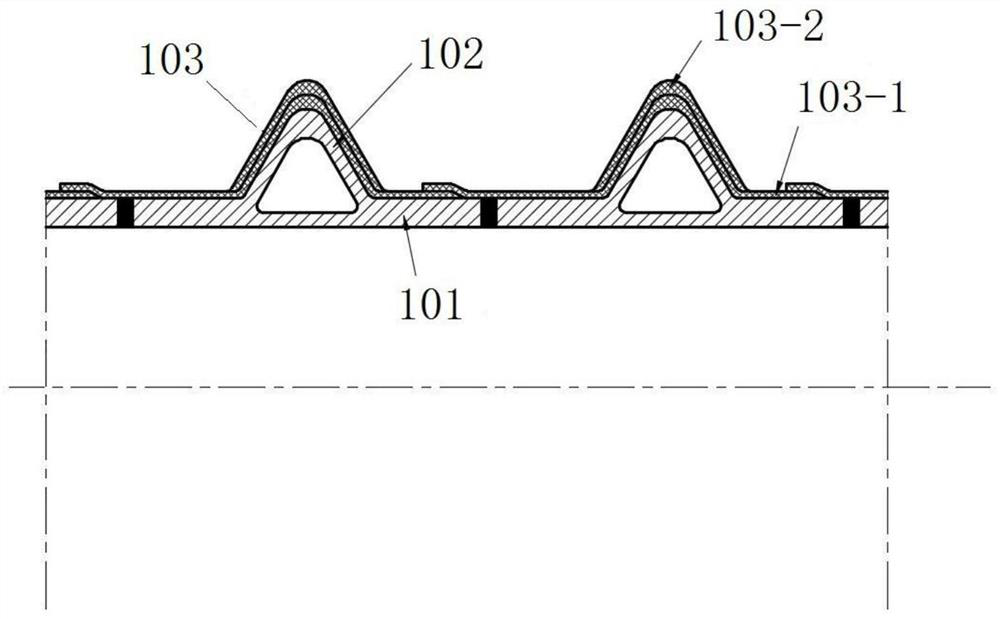

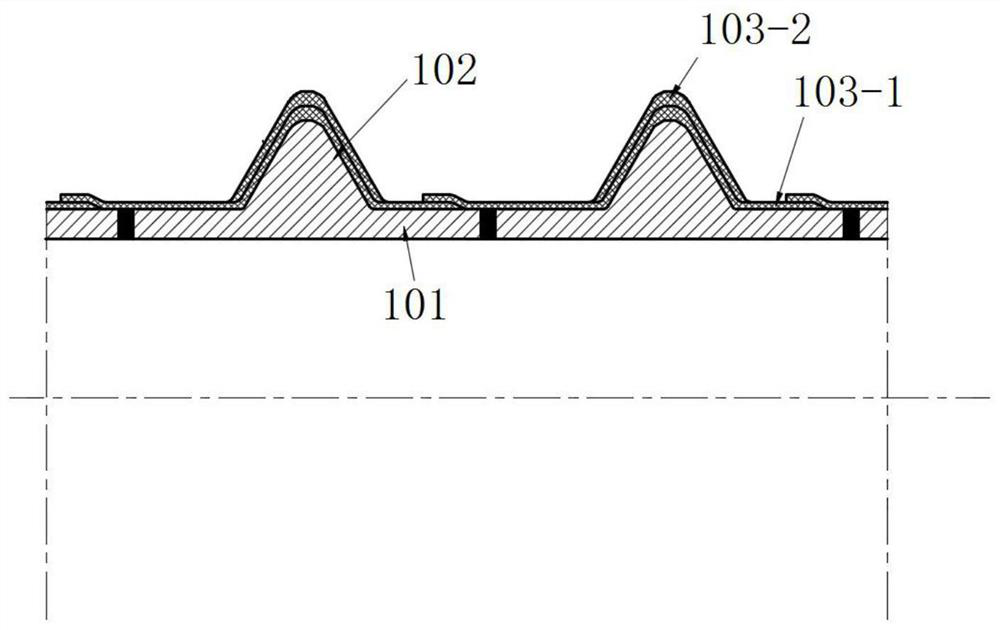

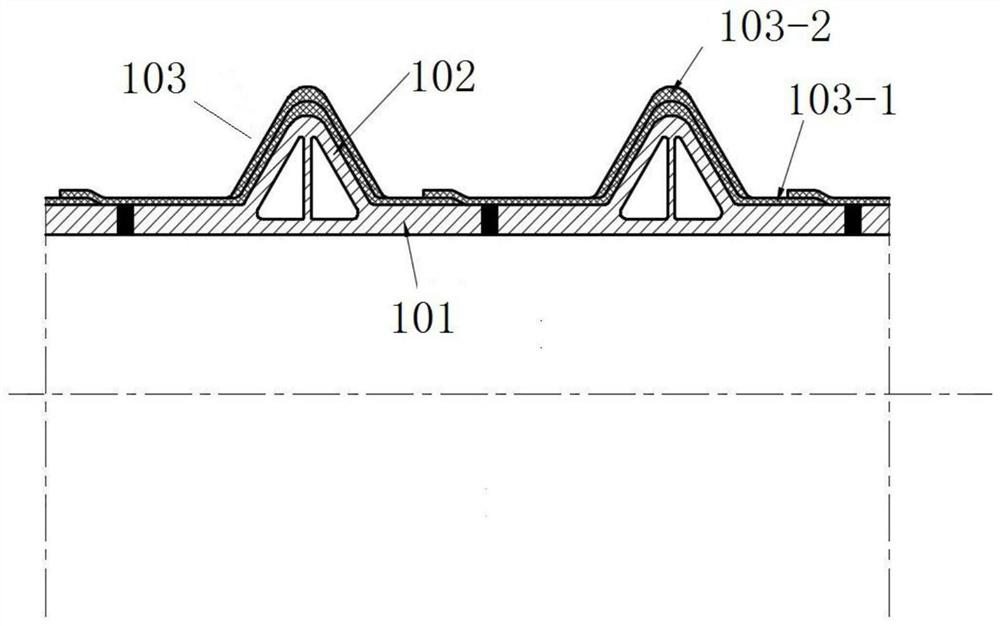

[0040] Such as Figures 1 to 4 As shown, this embodiment discloses a continuous fiber glass fiber board stirrup pipe composite arc-top triangular corrugated pipe, which includes an arc-top corrugated pipe 1, and the arc-top corrugated pipe 1 includes a plastic pressure-bearing inner tube made of inorganic reinforced plastics. Layer pipe 101 , the outer wall of the plastic pressure-bearing inner layer pipe 101 is provided with a spiral plastic reinforcement 102 . A continuous fiber prepreg stirrup tube 103 is welded on the outer wall of the pressure bearing layer 101 and the plastic reinforcement 102 .

[0041] Specifically, the continuous fiber prepreg stirrup tube 103 includes an inner layer tube composite fiber stirrup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com