Method and device for producing antiseptic pipe by adopting nano-coatings

A nano-coating, anti-corrosion pipe technology, applied in mechanical equipment, pipeline anti-corrosion/anti-rust protection, damage protection, etc. Long-term safe operation, avoiding instability and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

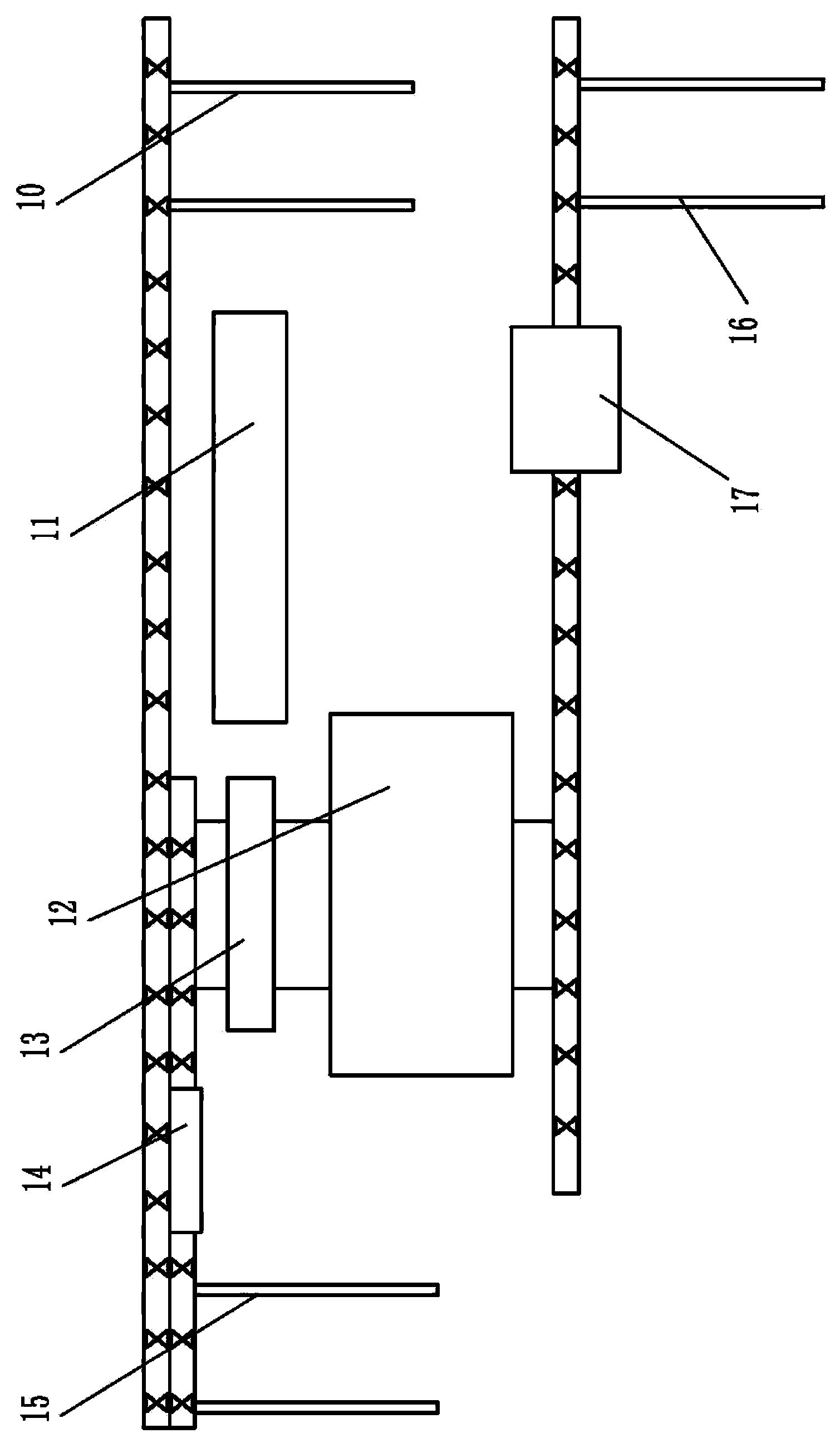

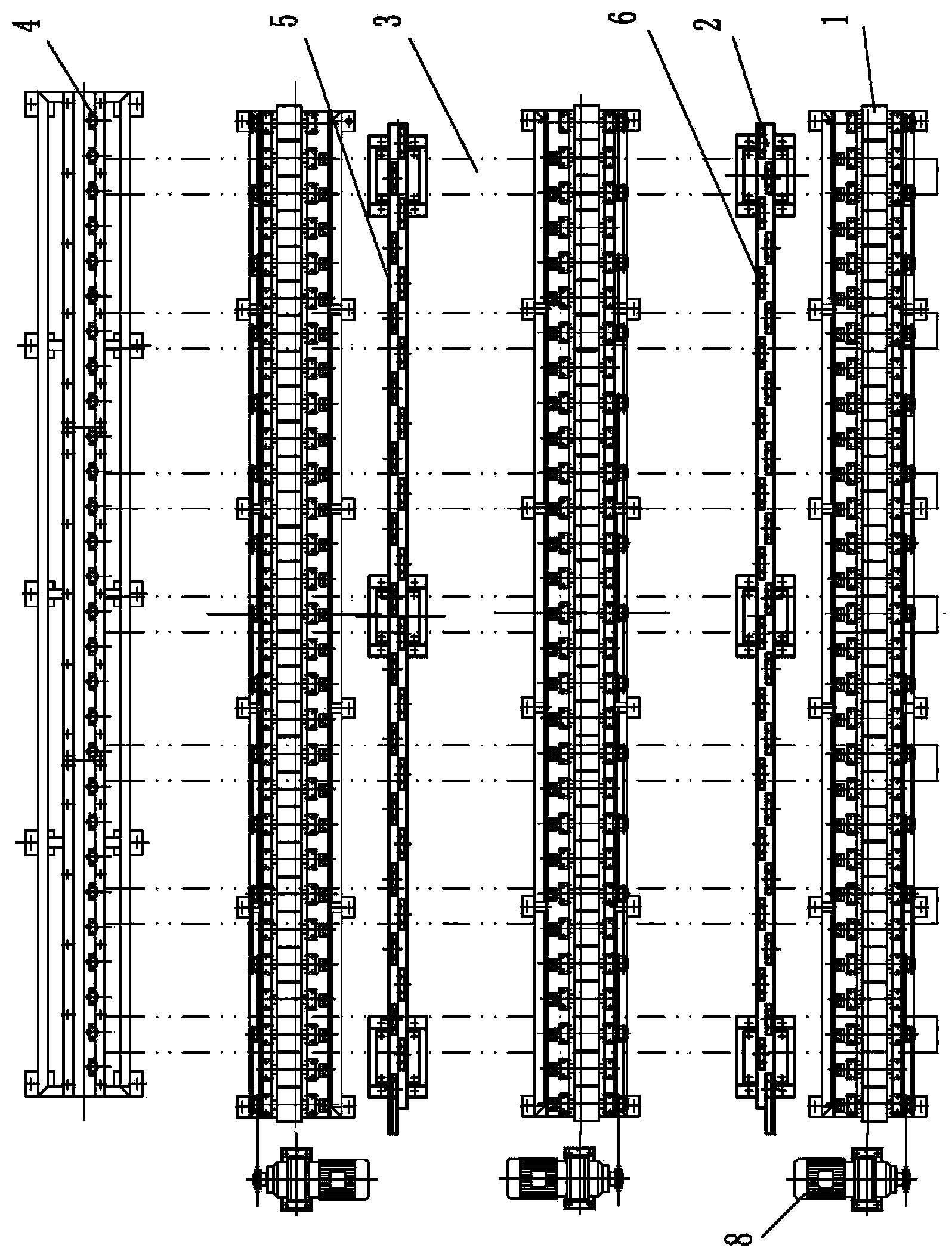

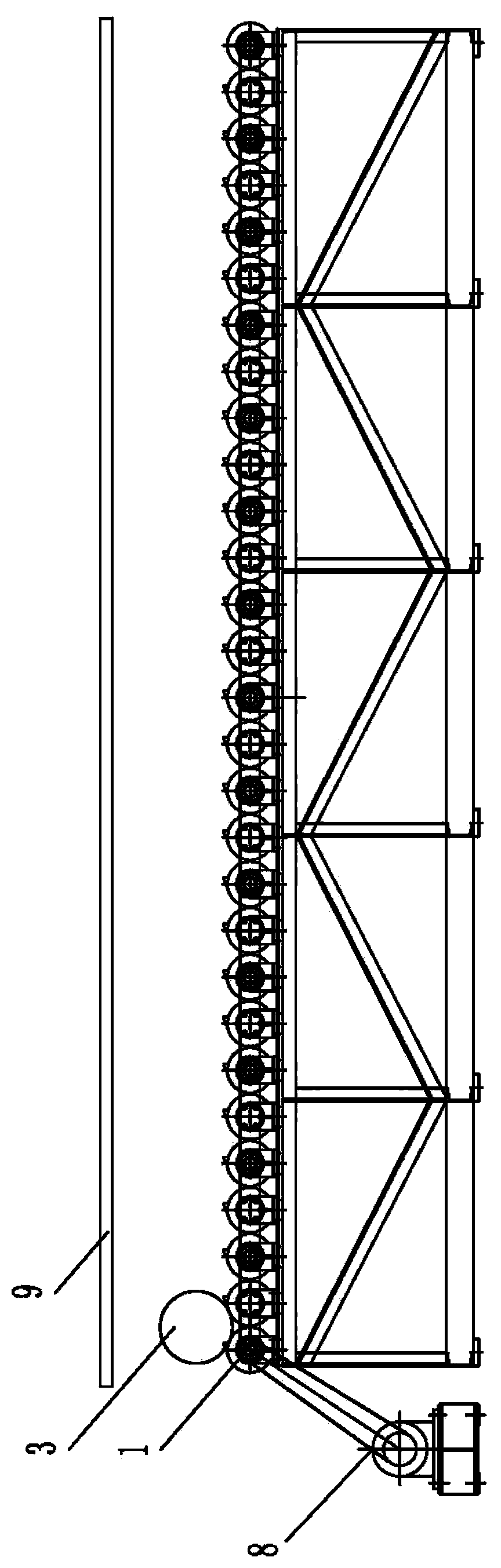

[0021] A kind of method that adopts nano coating to produce anticorrosion pipe, such as figure 1 As shown, the following steps are included, 1. The basic pipe is delivered to the electric preheater 14 for preheating, and the preheating temperature is 50 o C-80 o C, the preheating time is 1-1.5 minutes; the preferred parameter is that the basic tube is preheated in the electric preheater, and the preheating temperature is 80 o C, the preheating time is 1 minute. 2. Transport the preheated basic tube to the feeder 13, and use the airless high-pressure sprayer 11 to automatically spray the inner wall of the tube cavity, so that the spraying thickness of the nano-coating can reach 150um at one time; 3. Then the sprayed basic tube The pipe is transported to the homogenizer 12 for stepping, heating and homogenization. Reflective heating plates are installed at horizontal intervals above the homogenizer. The rotation speed of the basic pipe on the homogenizer is 35 rpm, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com