System and method for preventing rotary air preheater from being blocked by ammonium bisulfate ash deposition

A technology of air preheater and ammonium bisulfate, which is applied in the direction of combustion method, damage protection, heat exchange equipment, etc., can solve the problems such as the effect of smoke temperature is not obvious, so as to prevent the clogging of ammonium bisulfate ash accumulation, improve safety and Economic efficiency and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention is given below, and it is to be not limited to the following specific embodiments, and the equivalent transformations made by the present application technical scheme fall into the scope of the present invention.

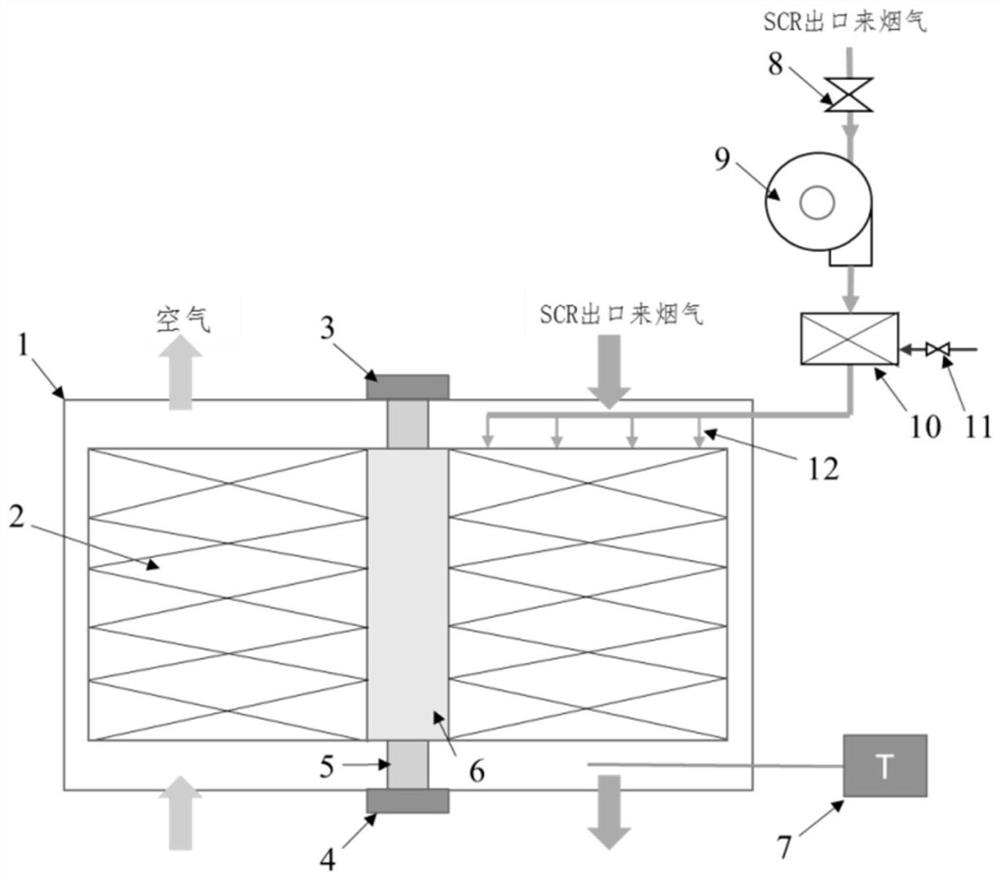

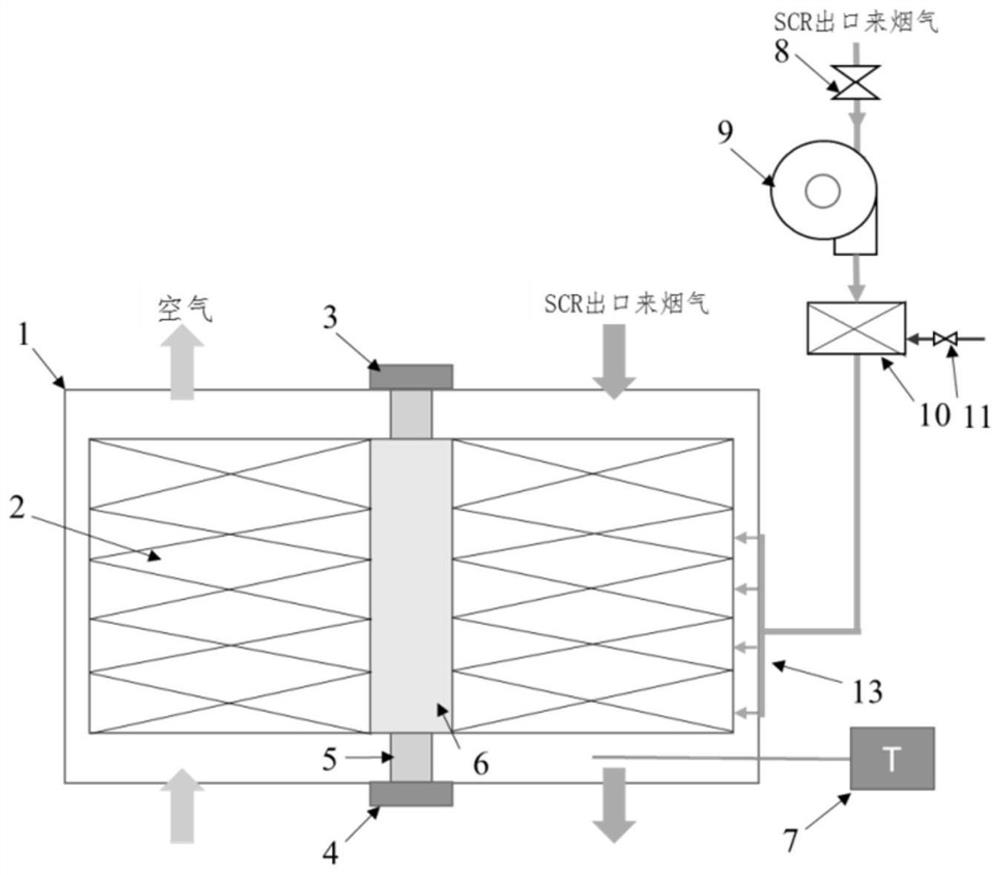

[0024]Compliance with the above technical solution, such asfigure 1 withfigure 2As shown, the present embodiment gives a system and method for preventing ambulatory ash blur of hydrogen sulfate in turn-type air preheater.

[0025]Seefigure 1 According to a system of preventing ambulatomy ambulfate, ambulatomy, an ammonium sulfate, including a smoke measuring device 7, a flue gas boost fan 9, and a flue gas heater 10; the smoke temperature measuring device 7 is mounted in air Preheater flue gas side exit, used to measure the exit flue gas temperature during the operation of the air preheater; the flue gas boost fan 9 is connected to the bypass flue gas baffle door 8, bypass flue gas baffle door 8 and SCR The exit flue is connected, and the bypass flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com