Annular sealing connection method of lining pipeline

A connection method and lining pipe technology, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, pipe protection, etc., can solve problems such as high welding temperature and loss of anti-corrosion ability of pipelines, and achieve good sealing effect, Achieve long-term safe operation and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

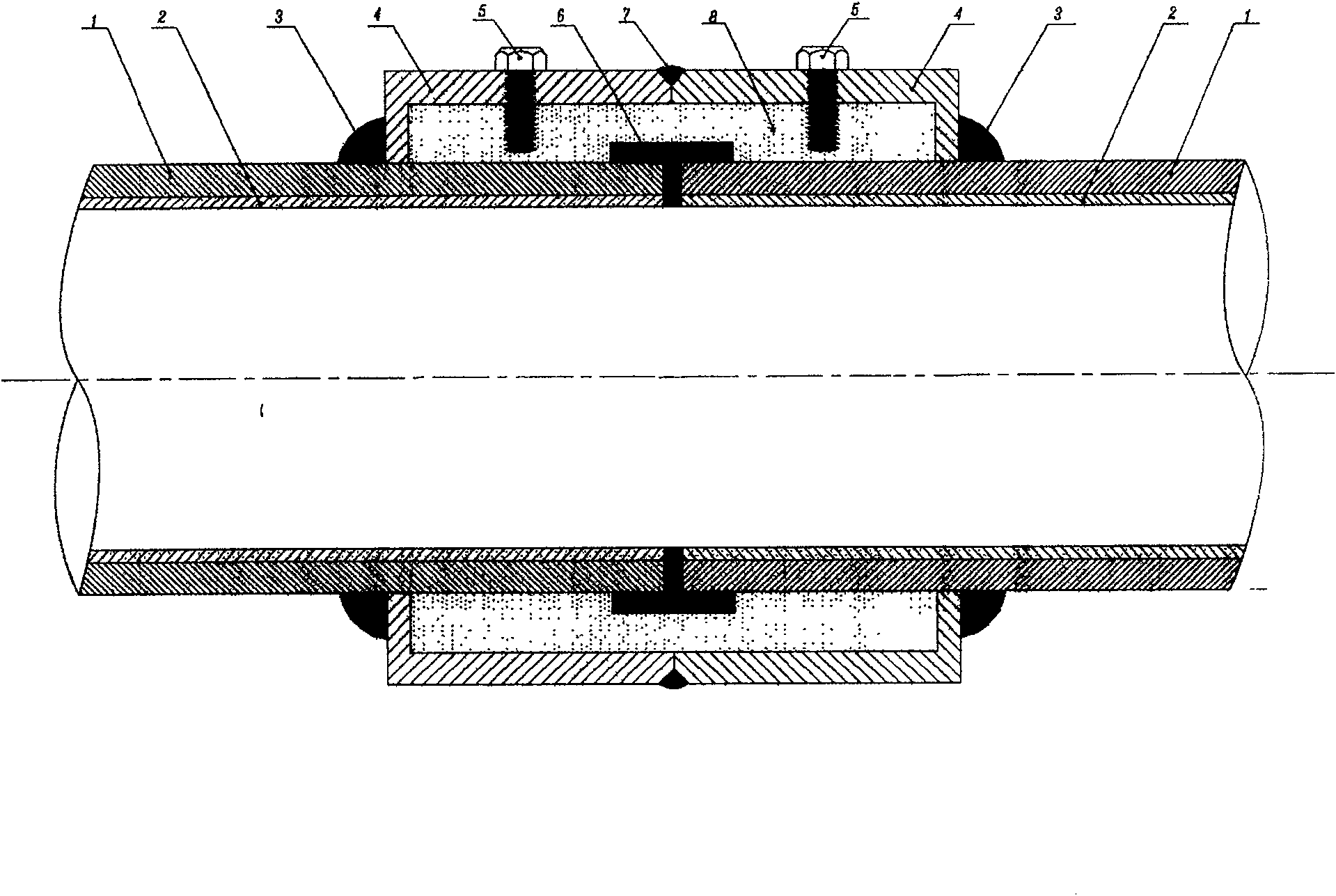

[0011] In the embodiment shown in the figure, the annular collar 4 is pre-welded at a certain distance from the nozzle of the steel pipe 1, the welded joint 3 is processed, and a hole is opened at the horizontal axis position of the upper surface of the annular collar 4, Then proceed to lining 2 making. At the construction site, first apply a special adhesive on the end face of the lining pipe and the inner wall of the centralizing joint 6, and then coat the centralizing joint 6 on the ends of the two connected lining pipes. The end faces of the two lining pipes should be close to each other. Righting the butt joint end face of the joint 6, welding the butt weld seam of the annular collar 4, and processing the welding joint 7: and then pressurizing and injecting a special seal into the annular gap through an opening on the annular collar 4 Glue 8. When the sealant overflows from the opening of the other annular coupling 4, screw the bolts 5 into the two holes and weld them wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com