Device and method for manufacturing non-woven fabric by mixing melt-blown subject as carrier and short cut fibers

A technology of ultra-short fiber and non-woven fabrics, which is applied in the field of non-woven fabrics manufacturing. It can solve the problems of easily affecting the working environment, not easy to comb and mix, and short fiber length, so as to ensure smoothness, cleanliness, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

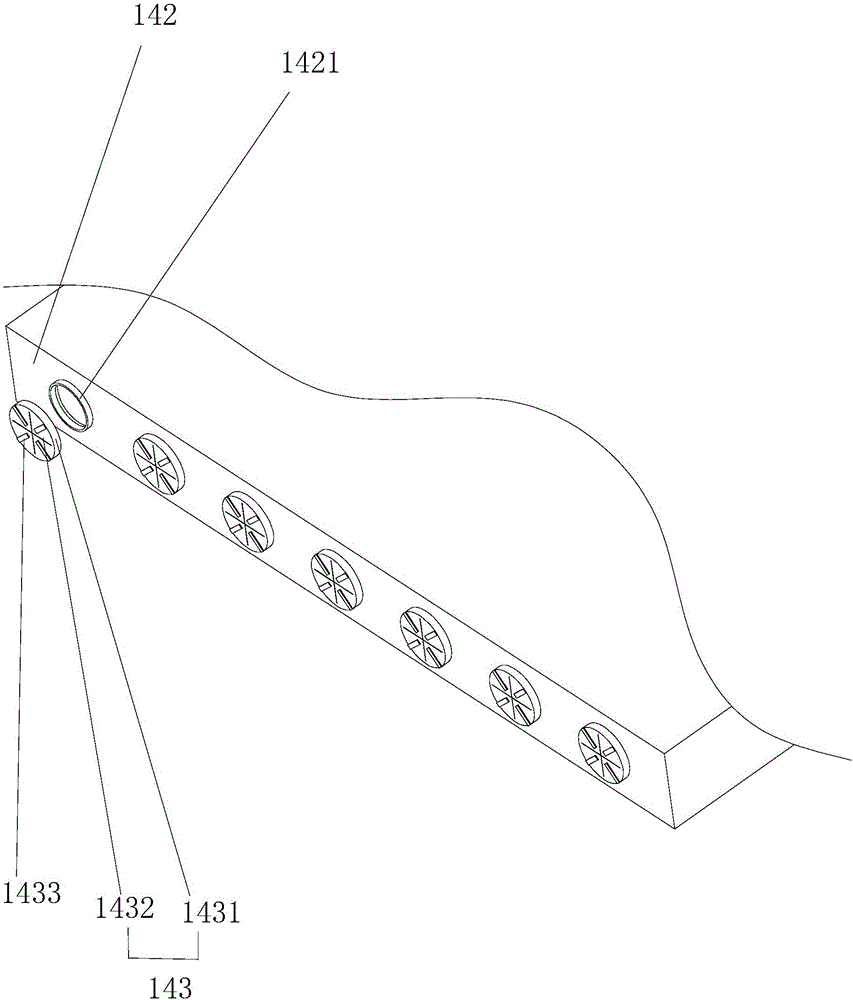

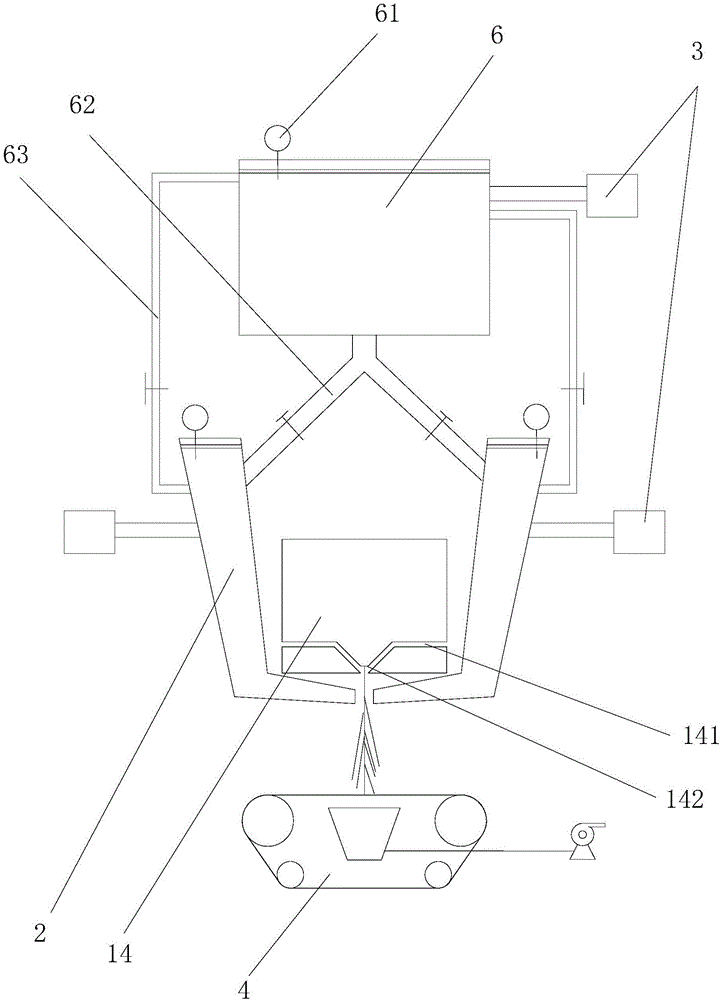

[0040] Embodiment 1: A kind of non-woven fabric manufacturing equipment that takes melt-blown as carrier and ultra-short fiber to mix, as figure 1As shown, it includes a meltblown device 1 and a feeding device. The melt-blowing device 1 comprises a collection box 11, a screw extruder 12, a metering pump 13, a spinning box 14 and a spinneret 142 connected in sequence, and the spinneret 142 is provided with a spinning nozzle for easy extrusion of spinning. hole. At the same time, a traction air duct 141 is provided at the spinneret 142, one end of the traction air duct 141 can be connected with a blower (not shown in the figure), and the other end is located at the spinneret hole; and the traction air duct 141 is distributed in the spinneret hole The two sides are arranged symmetrically.

[0041] The feeding device includes two airtight storage tanks 2 , which are arranged symmetrically on both sides of the spinning box body 14 . The cross-section of the airtight storage tank...

Embodiment 2

[0048] Embodiment 2: as image 3 As shown, the difference from Example 1 is that the non-woven fabric manufacturing equipment that uses melt-blowing as a carrier mixed with ultra-short fibers also includes an airtight auxiliary feeding storage tank 6, an airtight auxiliary feeding storage tank 6 and an airtight storage The tanks 2 are connected by pipelines, and the pipelines include a feed pipeline 62 and an air pressure equalization pipeline 63 . Airtight auxiliary feeding storage tank 6 can be one, and now feed pipeline 62 is Y-shaped, connects two airtight storage tanks 2 respectively, and electromagnetic valve can be set on feed pipeline 62; Air pressure balance pipeline 63 is two, The air pressure in the airtight auxiliary feeding storage tank 6 and the air pressure in the two airtight storage tanks 2 are balanced by two air pressure balance pipelines 63, so that ultra-short fibers enter from the feed pipeline 62, and the air pressure balance pipeline 63 is set There is...

Embodiment 3

[0050] Embodiment 3: as Figure 4 As shown, compared with Embodiment 1, the difference is that the draft air duct 141 is formed by clamping the side wall of the spinning box 14 and the side wall of the airtight storage tank 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com