Waste plastic recycling process

A waste plastic and process technology, applied in the field of waste plastic recycling technology, can solve the problems of broken plastic films, incomplete separation of films, and inability to ensure complete separation of garbage, etc., and achieve the effect of increasing adsorption efficiency and maintaining cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

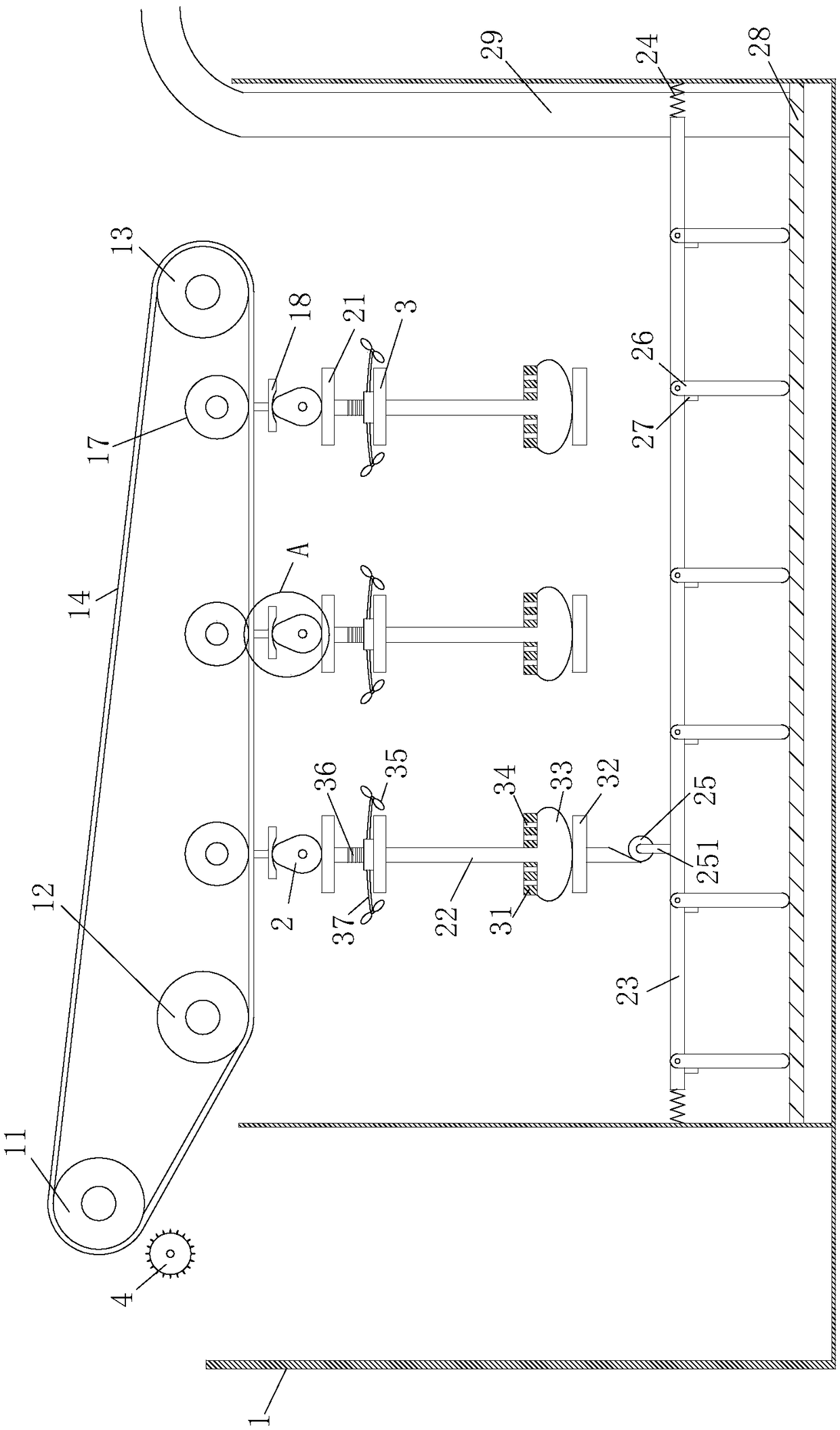

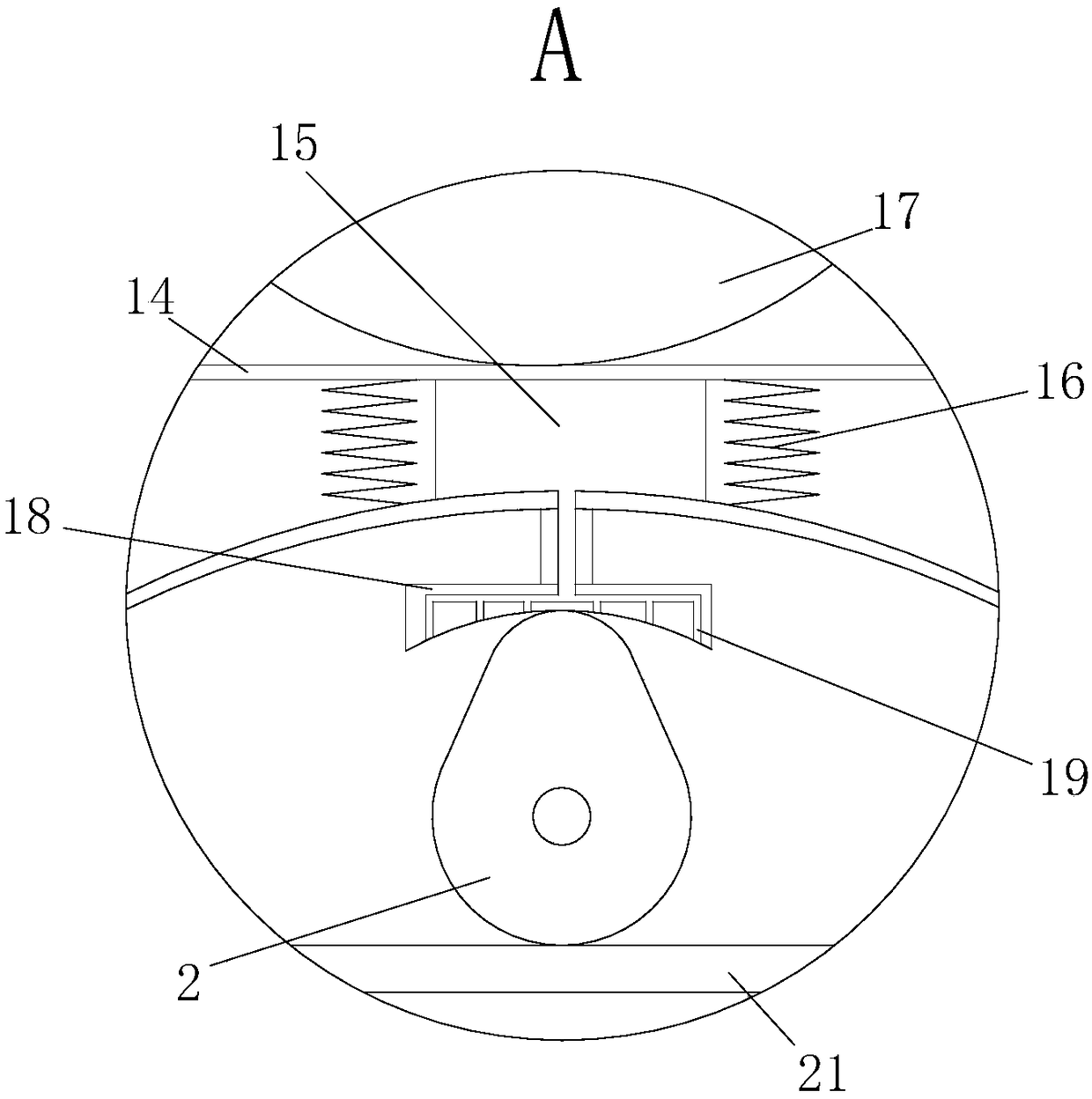

[0034] As an embodiment of the present invention, a first object-bearing plate 3 is provided below the extruding plate 21; the extruding rod 22 is set through the first object-bearing plate 3; An object-bearing plate 3 is fixedly provided with an air distribution plate 31 on the surface of the lower portion of the first object-bearing plate 3; a second object-bearing plate 32 is provided below the air distribution plate 31; the extruding rod 22 passes through the first Two object bearing plates 32 are provided; a second air bag 33 is fixedly connected between the air distribution plate 31 and the second object carrier plate 32, and a plurality of air holes 34 communicating with the second air bag 33 are provided on the air distribution plate 31; When working, the extrusion rod 22 moves up and down to drive the air distribution plate 31 to squeeze the second air bag 33, so that the gas or liquid in the second air bag 33 passes into the frame body 1 through the air hole 34, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com