Garbage bag extractor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

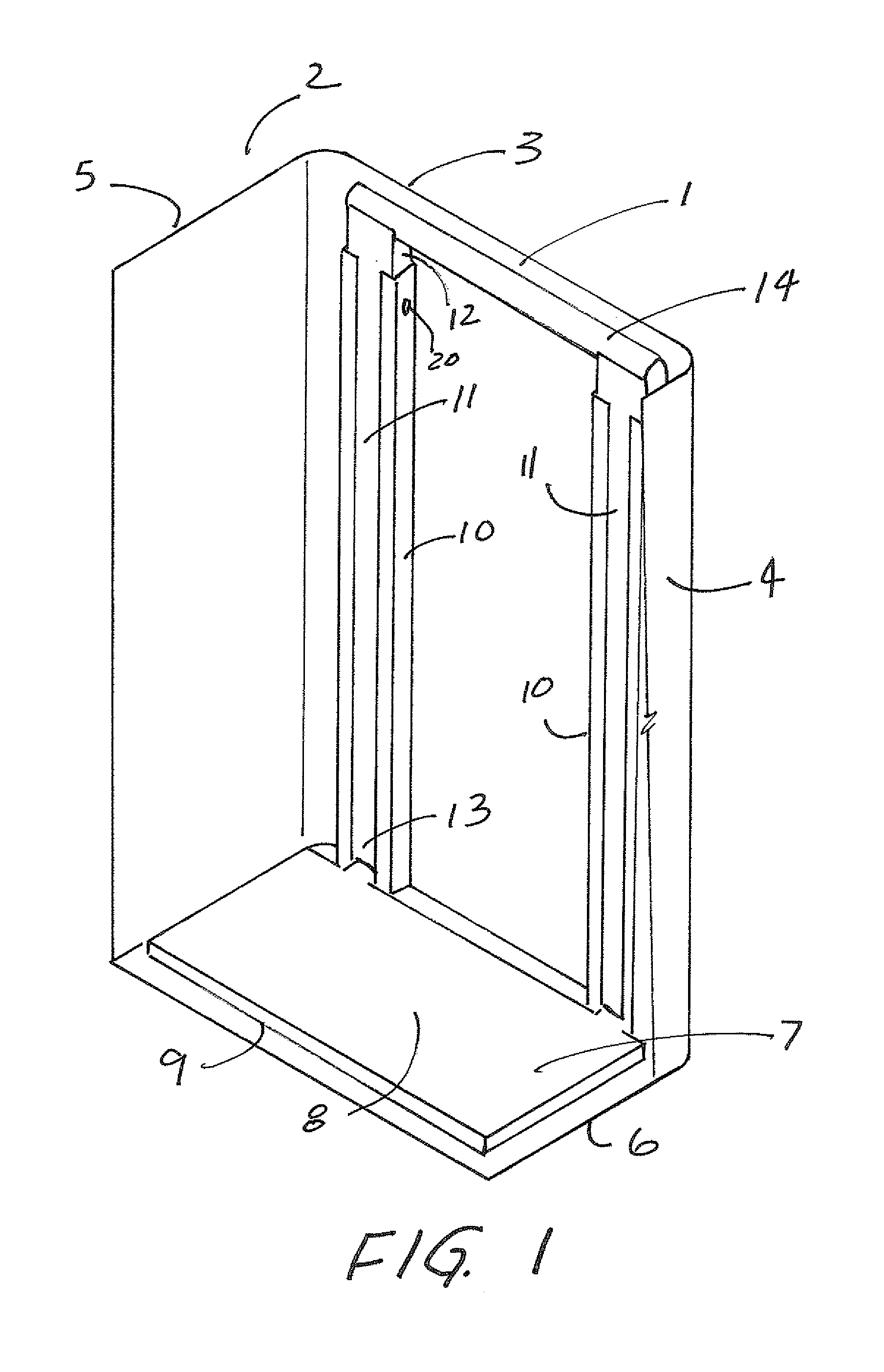

[0011]FIG. 1 depicts a trash can 2 with a manual embodiment of the inventive garbage bag extractor 1 in place. The front and right side 4 of the trash can 2 have been cut away for clarity. It is understood that a garbage bag would be placed in the trash can 2 to receive waste and garbage from above in the normal fashion. As shown, the garbage bag extractor 1 has a lifting platform 7 fitted to the cross sectional shape of the trash can 2 with a top side 8 and a bottom side 9, the lifting platform 7 resting in the bottom 6 of the trash can 2. At the top 8 of the lifting platform 7 are attached the bottom ends 13 of vertical lifting arms 11 that ride in vertical slide rails 10 attached to the rear interior side 3 of the trash can 2. The top ends 12 of the lifting arms 11 are attached to a pull handle 14. Also shown is at least one venting hole 20 meant to break the natural vacuum created when the lifting platform 7 is raised. In this embodiment, air would be drawn the slide rails 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com