A processing method for producing alcohol by adding cassava residue and molasses

A processing method and technology of cassava residue, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increased sulfuric acid consumption, equipment corrosion, environmental hazards, etc., to improve resource recycling and reduce equipment. The effect of reducing the loss and reducing the pressure of decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

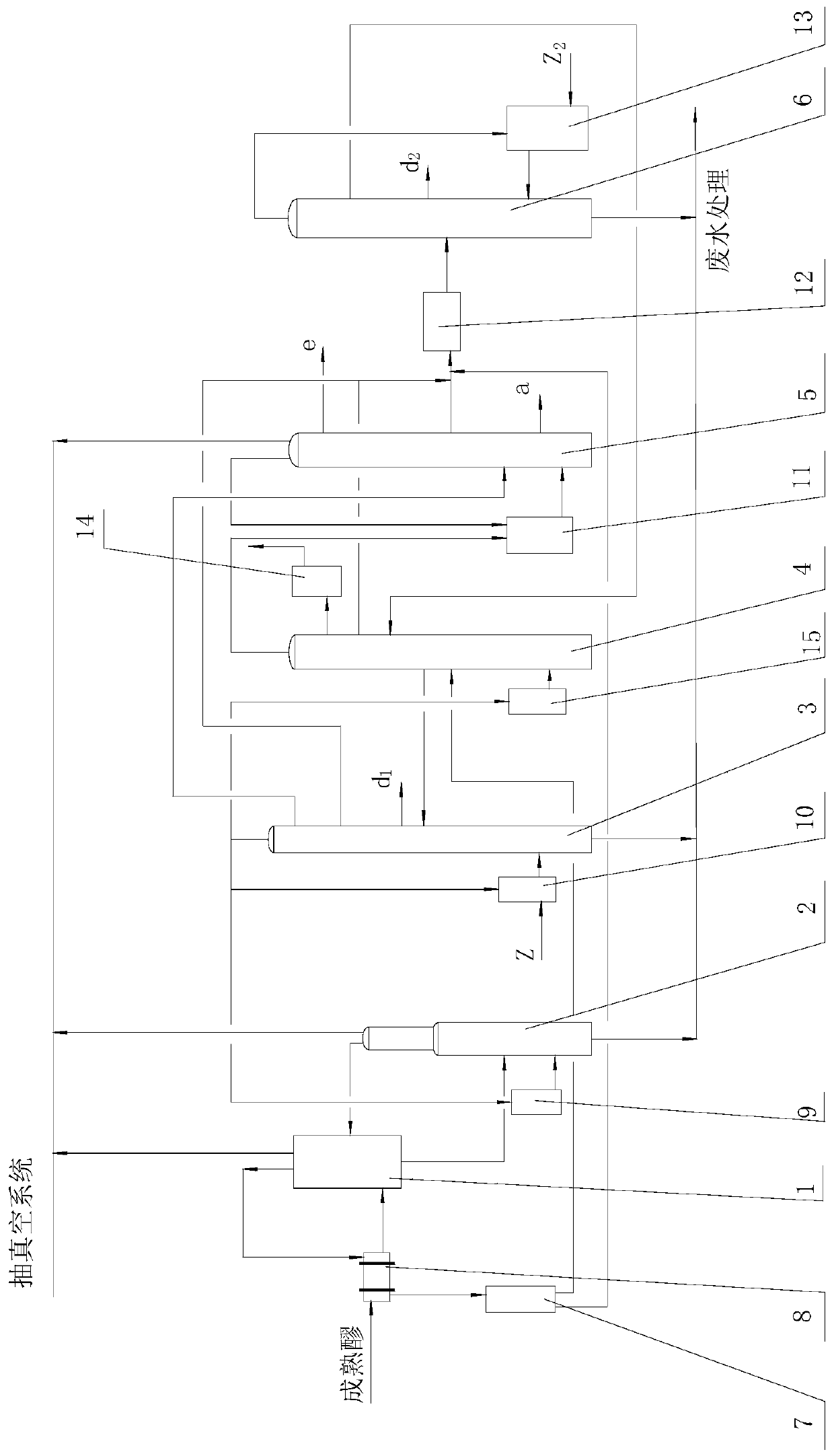

Method used

Image

Examples

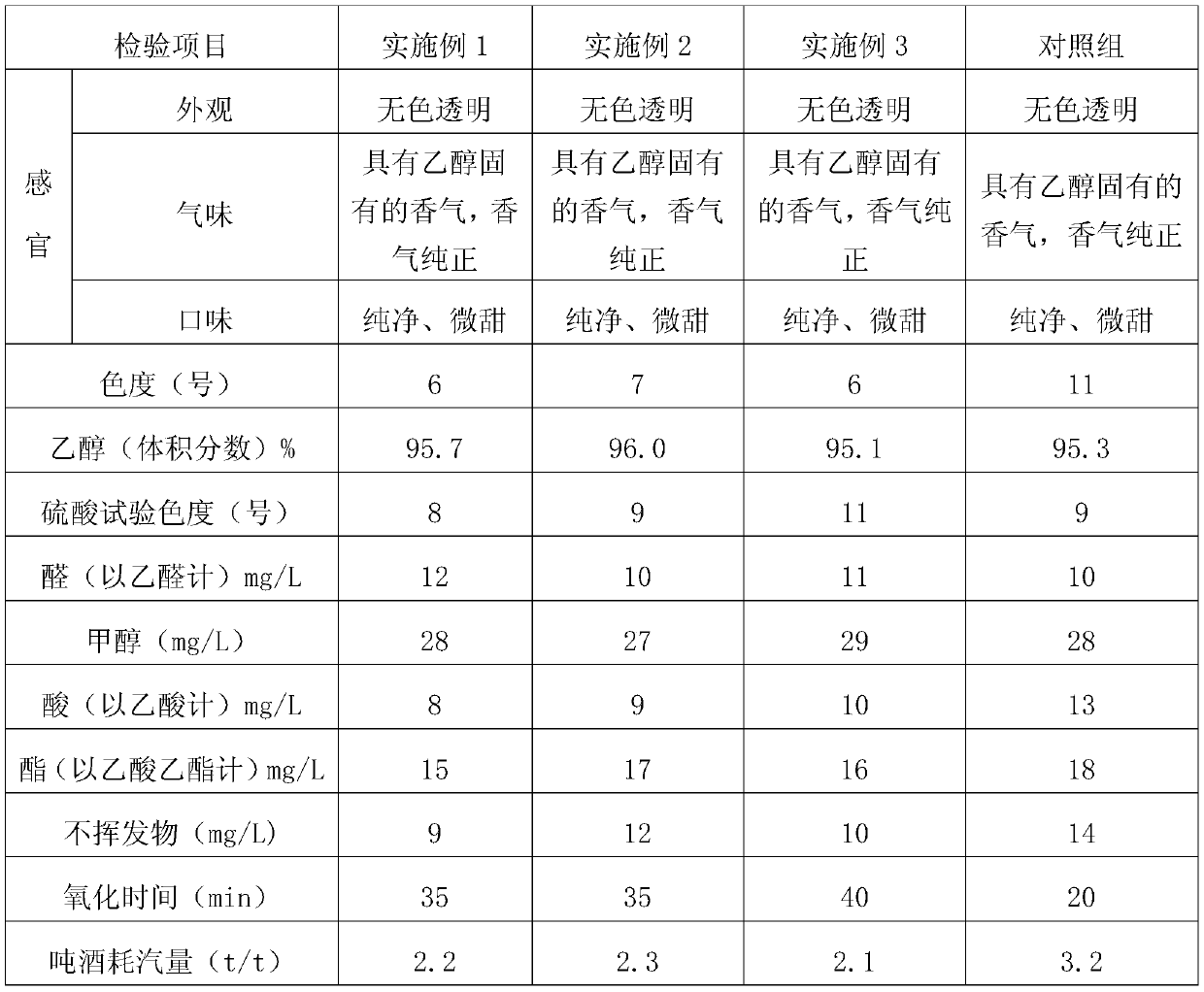

Embodiment 1

[0044] (1) Pretreatment: the cassava residue after starch extraction and waste molasses are mixed according to a weight ratio of 1:1 to obtain a mixture, the starch content of the cassava residue is 7%, and the brix of the molasses waste liquid is 70° Bx;

[0045] (2) Cooking: Add 10u / g of high temperature-resistant α-amylase to the mixture of step (1) for precooking, the precooking temperature is 50°C, and the precooking time is 20min. After the precooking is completed, it is heated to 95°C. The post-ripener is maintained for 90 minutes to obtain liquefied mash;

[0046] (3) Saccharification: the liquefied mash enters the mash pot for saccharification to obtain mash. The amount of saccharification enzyme added during the saccharification process is 150u / g. The saccharification temperature is 50°C and the saccharification time is 20 minutes;

[0047] (4) Fermentation: adopt continuous fermentation method to ferment to obtain mature mash, the alcohol concentration of mature ma...

Embodiment 2

[0050] (1) Pretreatment: the cassava dregs after starch extraction and waste molasses are mixed according to the weight ratio of 1:1 to obtain a mixture, the starch content of the cassava dregs is 9%, and the brix of the molasses waste liquid is 80° Bx;

[0051] (2) Cooking: add 15u / g high temperature resistant α-amylase to the mixture of step (1) for precooking, the precooking temperature is 60°C, the precooking time is 30min, after the precooking is completed, heat to 105°C The post-ripener is maintained for 120 minutes to obtain liquefied mash;

[0052] (3) Saccharification: the liquefied mash enters the mash pot for saccharification to obtain mash. The amount of saccharification enzyme added during the saccharification process is 200u / g. The saccharification temperature is 65°C and the saccharification time is 30 minutes;

[0053] (4) Fermentation: adopt continuous fermentation method to ferment to obtain mature mash, the alcohol concentration of mature mash is greater th...

Embodiment 3

[0056] (1) Pretreatment: the cassava residue after starch extraction and waste molasses are mixed according to a weight ratio of 1.5:1 to obtain a mixture, the starch content of the cassava residue is 8%, and the brix of the molasses waste liquid is 75 ° Bx;

[0057](2) Cooking: add 13u / g high temperature resistant α-amylase to the mixture of step (1) for precooking, the precooking temperature is 55°C, and the precooking time is 25min, after the precooking is completed, heat to 100°C The post-ripener is maintained for 100 minutes to obtain liquefied mash;

[0058] (3) Saccharification: the liquefied mash enters the saccharification pot for saccharification to obtain saccharification mash, the amount of saccharification enzyme added in the saccharification process is 180u / g, the saccharification temperature is 60°C, and the saccharification time is 25min;

[0059] (4) Fermentation: adopt continuous fermentation method to ferment to obtain mature mash, the alcohol concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com