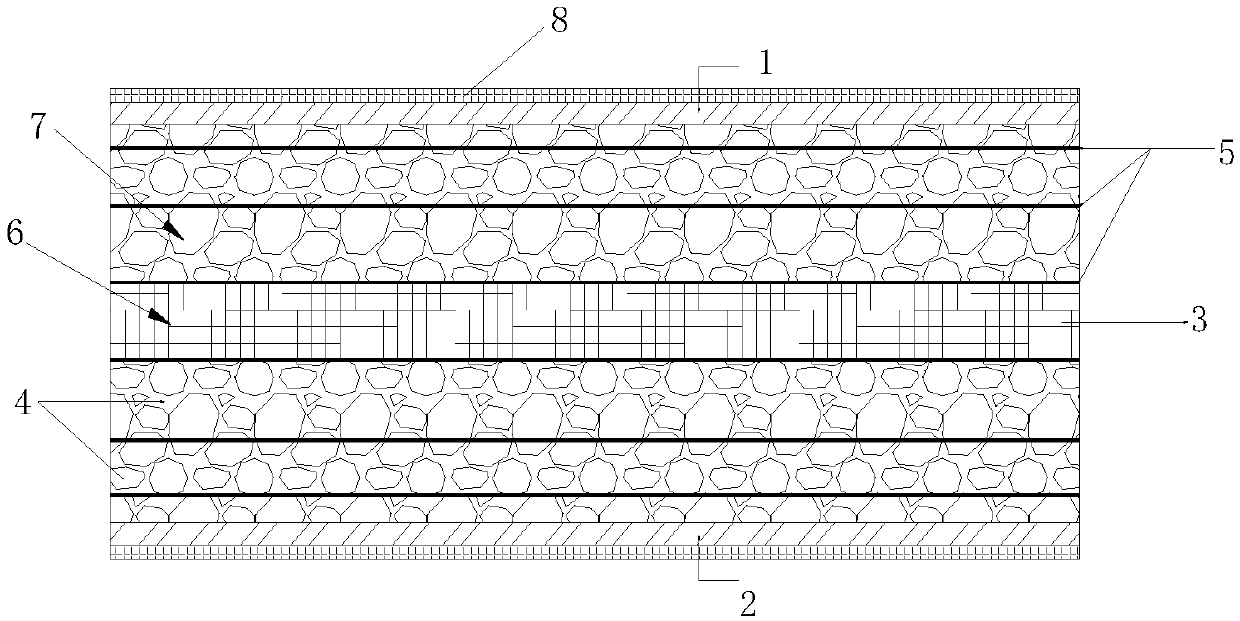

A kind of polymer composite board and preparation method thereof

A composite material board and polymer technology, applied in chemical instruments and methods, layered products, flat products, etc., can solve the problems of high maintenance costs, troublesome cracks, poor flammability and fire resistance, etc., to reduce handling costs, Easy to handle and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

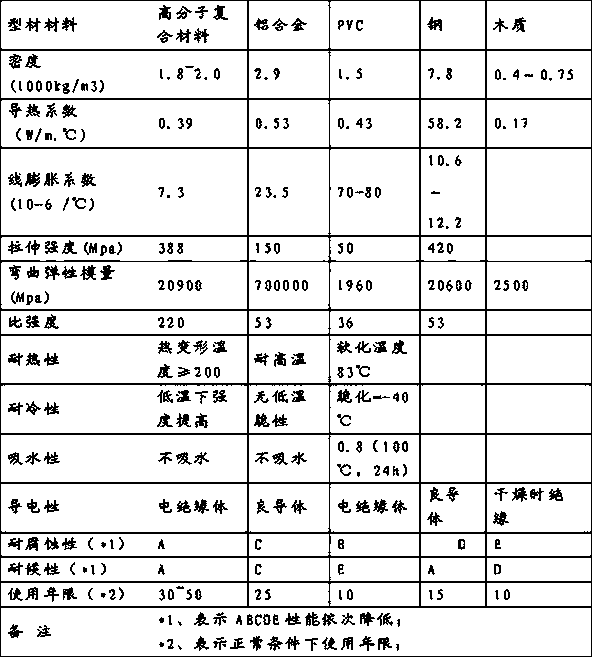

[0034] High-temperature curing stretching process: under the action of traction, the continuous roving, felt, tape or cloth soaked in glue is heated, extruded, pultruded and solidified through the mold to continuously produce unlimited lengths. Polymer composite profiles.

[0035] 1. Raw materials and ingredient ratios for high temperature curing stretching process

[0036] (1) Reinforcement material

[0037] The reinforcing material of high temperature curing stretching process is mainly polymer fiber and its products, such as roving, glass fiber mat and aramid fiber, carbon fiber, ultra-high molecular weight polyethylene fiber and basalt fiber, etc.; the proportion is the weight percentage of the product About 45% to 60%;

[0038] (2) Resin matrix

[0039] In the high-temperature curing stretching process, unsaturated polyester resin, epoxy resin, vinyl resin, thermosetting methacrylic resin, modified phenolic resin, flame-retardant resin, polyurethane resin, etc. are sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com