Six-arm stellate organic light-emitting material and organic electroluminescent device adopting the material

A luminescent material and electroluminescence technology, applied in luminescent materials, electro-solid devices, electrical components, etc., can solve the problems of poor film formation, solvent-dependent fluid properties, easy dewetting, etc., to improve device efficiency and radiation. Luminous efficiency, clear structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

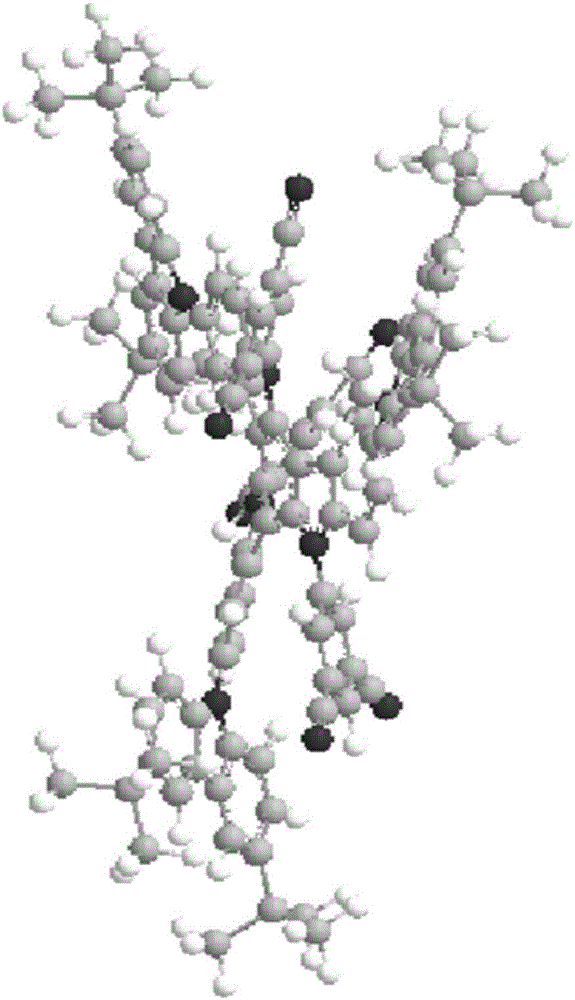

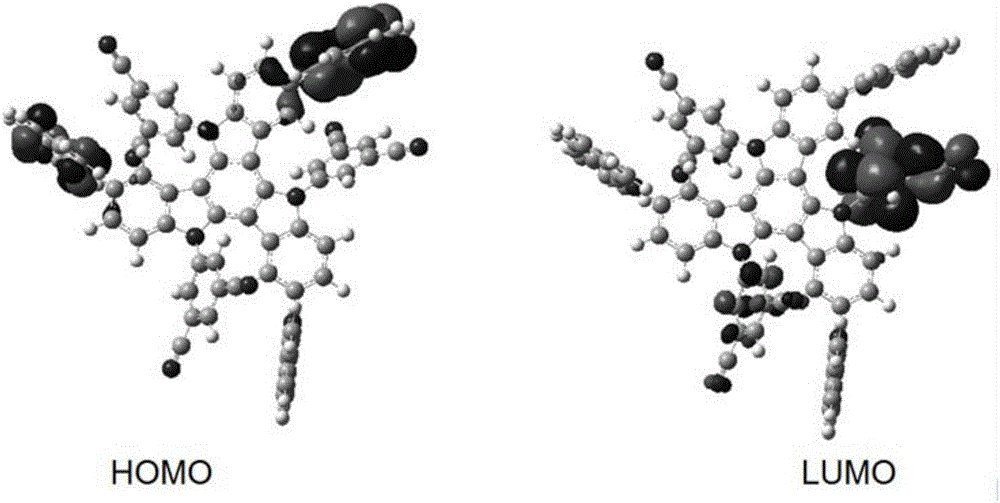

[0024] Example 1: Preparation of six-arm star-shaped organic light-emitting material M1:

[0025] Add 4 g (30 mmol) of the compound indol-2-one and 30 mL of phosphorus oxychloride into a two-necked flask, and raise the temperature to reflux under a nitrogen atmosphere to react with stirring for 8 h. Cool to room temperature after the reaction is completed, slowly pour the reaction solution into ice water to quench with stirring, adjust to neutral with 2M NaOH solution, filter the solid under reduced pressure and wash the solid with 20 mL of methanol to obtain a brown crude product, which is recrystallized with acetone 2.2 g of trimeric carbazole was obtained with a yield of 63%. MS (ESI-TOF): m / z: 345.1034. 1 H NMR (400MHz, DMSO-d 6 ): δ / ppm, 11.86 (s, 3H), 8.66 (d, 3H), 7.71 (d, 3H), 7.41-7.28 (m, 6H).

[0026] Under nitrogen atmosphere, add 1g (2.9mmol) trimeric carbazole, 0.1g sodium hydride (3.6mmol) into 20mL anhydrous tetrahydrofuran and stir to dissolve, add 1.4g (9....

Embodiment 2

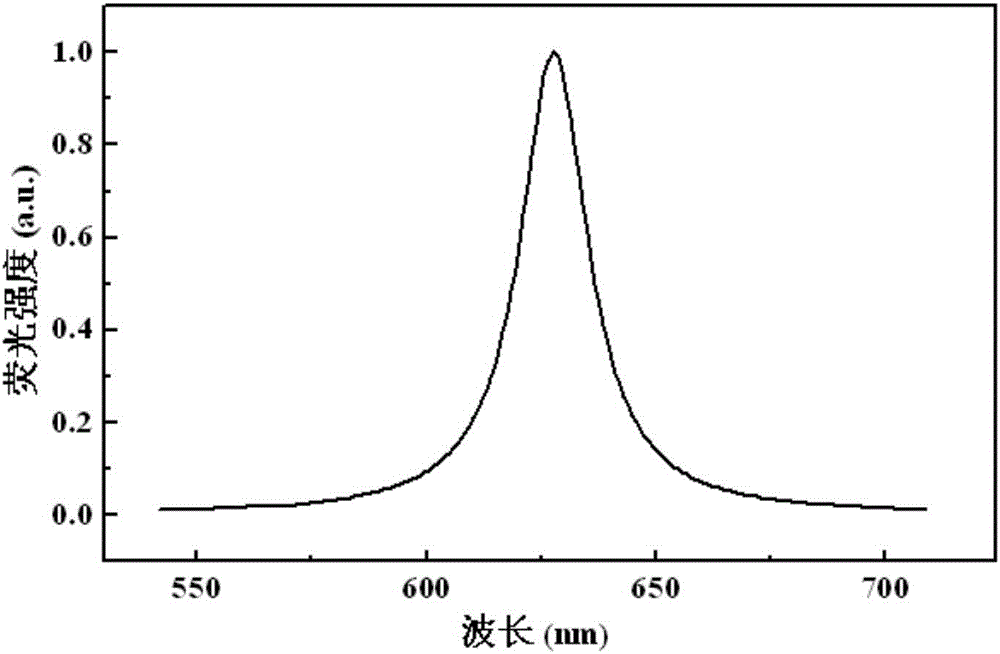

[0035] Example 2: A non-doped organic electroluminescent device using the six-armed star-shaped organic light-emitting material M1 as the main light-emitting material:

[0036] The organic electroluminescence device of present embodiment comprises: 1. glass substrate layer; 2. transparent anode (ITO); Ethylene sulfonic acid) (PEDOT:PSS); 4. The light-emitting layer is M1; 5. The electron transport layer is 1,3,5-tris[(3-pyridine grade)-3-phenyl]benzene (TmPyPB); 6. Metal cathode (A1 / LiF), such as Figure 4 shown.

[0037] The performance of the device was detected by Spectroscan PR705 spectrometer and Keithley 236 current and voltage source measurement system, and the results are shown in Table 2:

[0038] Table 2 Performance data of organic electroluminescent devices with M1 as the light-emitting host

[0039]

[0040] The non-doped device using the six-armed star-shaped organic light-emitting material M1 as the host light-emitting material has achieved a maximum extern...

Embodiment 3

[0041] Example 3: A doped organic electroluminescent device using the six-armed star-shaped organic light-emitting material M1 as a light-emitting object:

[0042] The organic electroluminescent device of this embodiment uses M1 as the light-emitting guest, and the doped device structure of the polymer material PVK as the main body is as follows Figure 5 As shown, including: 1. Glass substrate layer; 2. Transparent anode (ITO); 3. The hole injection layer is poly(3,4-ethylenedioxyethylthiophene)-poly(styrenesulfonic acid) (PEDOT :PSS); 4. The light-emitting layer is PVK:M1 or DCJTB; 5. The electron transport layer is 1,3,5-tris[(3-pyridine grade)-3-phenyl]benzene (TmPyPB); 6. Metal cathode (Al / LiF)

[0043] The performance of the device was detected by Spectroscan PR705 spectrometer and Keithley 236 current and voltage source measurement system, and the results are shown in Table 3:

[0044] Table 3 Performance data of organic electroluminescent devices with M1 as doping gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com