Method and device for preventing m-phthalonitrile from being caked

A technology of isophthalonitrile and m-xylene, which is applied in the field of preparation of fine organic compounds, can solve problems such as increasing labor force and labor intensity, not being able to increase packaging capacity, and easy adhesion and agglomeration, so as to reduce labor intensity and reduce dust pollution , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preventing the agglomeration of isophthalonitrile in this embodiment, ammonia and m-xylene are vaporized and enter the fluidized bed through the vaporizer to carry out the ammoxidation reaction, and the product enters the thin-walled receiver through the oil cooler to carry out Cooling and receiving, the product is washed intermittently into the washing tank with water, centrifuged, and dried. After the product is dried, it enters the silo through the auger conveyor, and a granulator and a vibrating screen are added behind the silo, and at the same time, the air is transported to the bag for dust removal; Isophthalonitrile dry powder is agglomerated into dense and hard plates under high pressure, and the plates are crushed by rolling. The material is conveyed by a single screw, and the material is brought into the gap between two rollers that rotate in opposite directions. The surface of the roller is gear-shaped. At the same time, olive-shaped grooves are c...

Embodiment 2

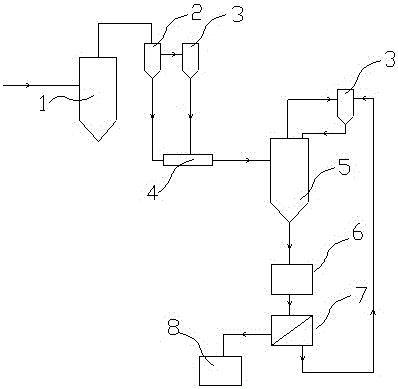

[0024] Such as figure 1 As shown, a device for preventing the agglomeration of isophthalonitrile in this embodiment includes a drying tower 1, a cyclone dust removal device 2, a bag dust removal device 3, an auger conveyor 4, a silo 5, and a granulator 6 , vibrating screen 7 and packing device 8; described drying tower 1, cyclone dedusting device 2, auger conveyor 4, feed bin 5, granulator 6, vibrating screen 7 and packing device 8 are arranged in series successively, and described cyclone dedusting device The dust outlet of the device 2 is connected with the bag dust removal device 3, and the dust outlet of the vibrating screen 7 is connected with the silo 5 through the air conveying pipeline.

[0025] The granulator 6 is fed by a single-screw feeder; the granulator includes two rollers that rotate in opposite directions, the surface of the rollers is gear-shaped, and grooves are grooved on the inner edge of the rollers to form an olive shape.

[0026] A bag dust removal dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com