Method for separating cyclohexane-methanol heterogeneous azeotrope through double-tower rectification

A double-tower rectification and cyclohexane technology, which is applied in the direction of distillation purification/separation, chemical instruments and methods, and preparation of organic compounds, can solve the problems of implementation and application without separation and low separation effect, and achieve product Purity improvement, effect of improving purity and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

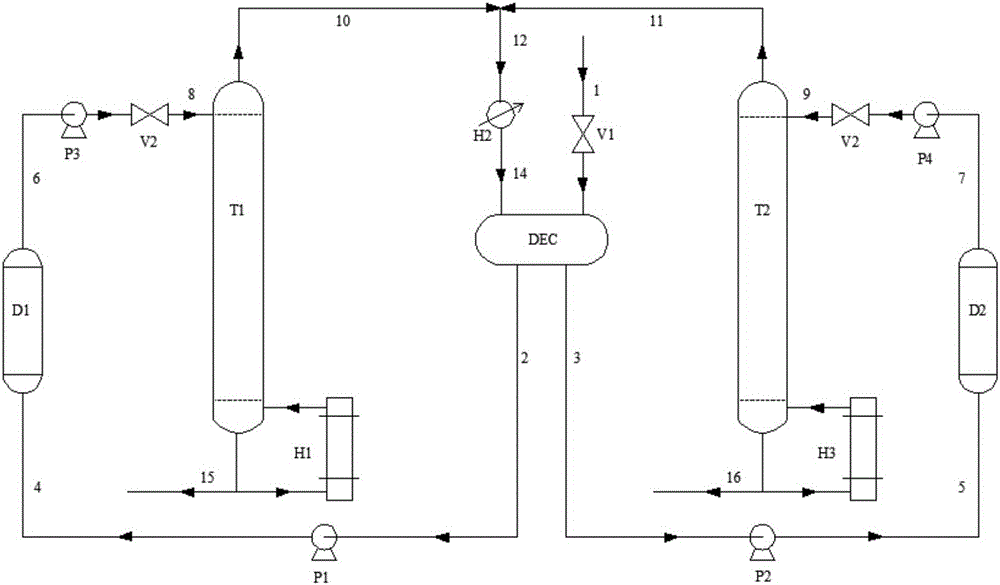

[0032] The feed temperature is 25°C, the flow rate is 1000kg / h, the pressure is 1atm (absolute pressure), the feed contains 40% cyclohexane and 60% methanol. After the materials are separated in the phase separator (DEC), the methanol phase Enter the methanol tower (T1) from the first tray, the operating pressure is 0.5atm (absolute pressure), the theoretical number of plates is 20, the reflux ratio is 2.0, the top temperature is 39.86℃, and the bottom temperature is 50.26℃; The alkane phase enters the cyclohexane tower (T2) from the first tray, the operating pressure is 0.5atm (absolute pressure), the theoretical number of plates is 20, the reflux ratio is 2.9, the top temperature is 38.24℃, and the bottom temperature is 66.45 ℃; The mass fraction of cyclohexane product obtained after separation is 99.92%, the recovery rate is 99.92%, the methanol purity is 99.95%, and the recovery rate is 99.96.

Embodiment 2

[0034] The feed temperature is 25℃, the flow rate is 1000kg / h, the pressure is 1atm (absolute pressure), the feed contains 60% cyclohexane and 40% methanol. After the materials are separated in the phase separator (DEC), the methanol phase Enter the methanol tower (T1) from the first tray, the operating pressure is 0.5atm (absolute pressure), the number of theoretical plates is 25, the reflux ratio is 2.8, the top temperature is 37.16℃, and the bottom temperature is 54.54℃; cyclohexane The alkane phase enters the cyclohexane tower (T2) from the first tray, the operating pressure is 0.5atm (absolute pressure), the theoretical number of plates is 23, the reflux ratio is 2.8, the top temperature is 40.25℃, and the bottom temperature is 69.89 ℃; The mass fraction of cyclohexane product obtained after separation is 99.94%, the recovery rate is 99.95%, the purity of methanol is 99.89%, and the recovery rate is 99.89.

Embodiment 3

[0036] The feed temperature is 25°C, the flow rate is 1100kg / h, and the pressure is 1atm (absolute pressure). The feed contains 80% cyclohexane and 20% methanol. After the materials are separated in the phase separator (DEC), the methanol phase Enter the methanol tower (T1) from the first tray, the operating pressure is 0.5atm (absolute pressure), the theoretical number of plates is 28, the reflux ratio is 3.4, the top temperature is 40.25℃, and the bottom temperature is 58.46℃; The alkane phase enters the cyclohexane tower (T2) from the first tray, the operating pressure is 0.5atm (absolute pressure), the theoretical number of plates is 26, the reflux ratio is 3.2, the top temperature is 43.46°C, and the bottom temperature is 73.21 ℃; The mass fraction of cyclohexane product obtained after separation is 99.98%, the recovery rate is 99.98%, the purity of methanol is 99.99%, and the recovery rate is 99.99.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com