Stone crystal face processing composition and preparation method of composition

A composition and stone technology, applied in the direction of polishing composition, chemical instruments and methods, etc., can solve the problems of poor anti-slip performance, achieve the effects of improving anti-slip performance, convenient and quick maintenance, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Embodiment 1: the preparation of crystallization agent of the present invention

[0102] The crystallization agent product A of the present invention was prepared by adopting the following formulation of the crystallization agent.

[0103]

[0104] The preparation method is as follows:

[0105] Add magnesium fluorosilicate to deionized water, stir with a paddle stirrer until the magnesium fluorosilicate is completely dissolved, stir for 15-20 minutes, control the stirring speed at 60 rpm, until it is completely dissolved and completely dissolved in water Add fumaric acid and citric acid in the resulting solution, stir for 5 minutes; continue to add polypropylene wax emulsion (AQUACER 1401 of BYK company), adjust the stirring speed to 40 rpm, stir for 10 minutes and stir evenly; finally add ethyl alcohol Glycol butyl ether, stirred for 20 minutes. The temperature needs to be controlled at 10-30 degrees Celsius throughout the process. And the containers used shoul...

Embodiment 2

[0106] Embodiment 2: the preparation of crystallization agent of the present invention

[0107] Using the same preparation method as in Example 1, the crystallization agent product B of the present invention was prepared according to the following formulation of the crystallization agent.

[0108]

[0109] The preparation method is as follows:

[0110] Add magnesium fluorosilicate to deionized water, stir with a paddle stirrer until the magnesium fluorosilicate is completely dissolved, stir for 15-20 minutes, control the stirring speed at 60 rpm, until it is completely dissolved and completely dissolved in water Add fumaric acid, citric acid and tartaric acid in the resulting solution, stir for 5 minutes; add calcium chloride, stir for 5 minutes; continue to add polytetrafluoroethylene wax emulsion (TE 3875 of Dupont company), adjust the stirring speed to 40 rpm Every minute, stir for 10 minutes to stir evenly; finally add diethylene glycol monoethyl ether and stir for 2...

Embodiment 3

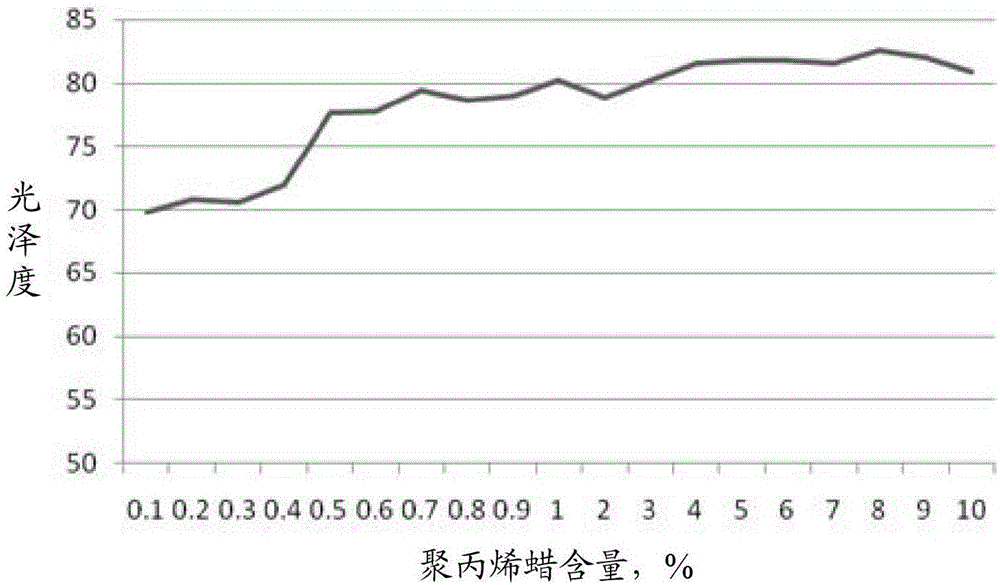

[0111] Embodiment 3: Contain the test of crystallization agent floor performance of the present invention

[0112] The present invention mainly tests the influence of the crystallization agent product on the gloss and smoothness of the stone surface after being applied on the stone. Wherein, the test method is as follows.

[0113] (1) Surface gloss measurement

[0114] Instrument: BYK three-angle gloss meter

[0115] ASTM method: D1455

[0116] Test steps: Make sure that there is no dust or particles on the surface of the object to be tested. If there is any, wipe it off with a clean dry cloth, measure the gloss of 60 degrees with a gloss meter, and measure the average value of at least ten different points on the surface of the object. Also record the standard deviation.

[0117] (2) Anti-slip measurement

[0118] Name: Static Coefficient of Friction (SCOF) Measurement Method

[0119] Instrument: BOT 3000

[0120] Method: ANSI / NFSI B101.1

[0121] Test steps: Make s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com