Chemical device and method for preparing ultra-fine rare earth compound through device

A technology of rare earth compounds and chemical industry, applied in the direction of rare earth metal compounds, chemical instruments and methods, rare earth metal oxides/hydroxides, etc. Problems such as growing up, to achieve the effect of simple structure, convenient use, and reduced reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

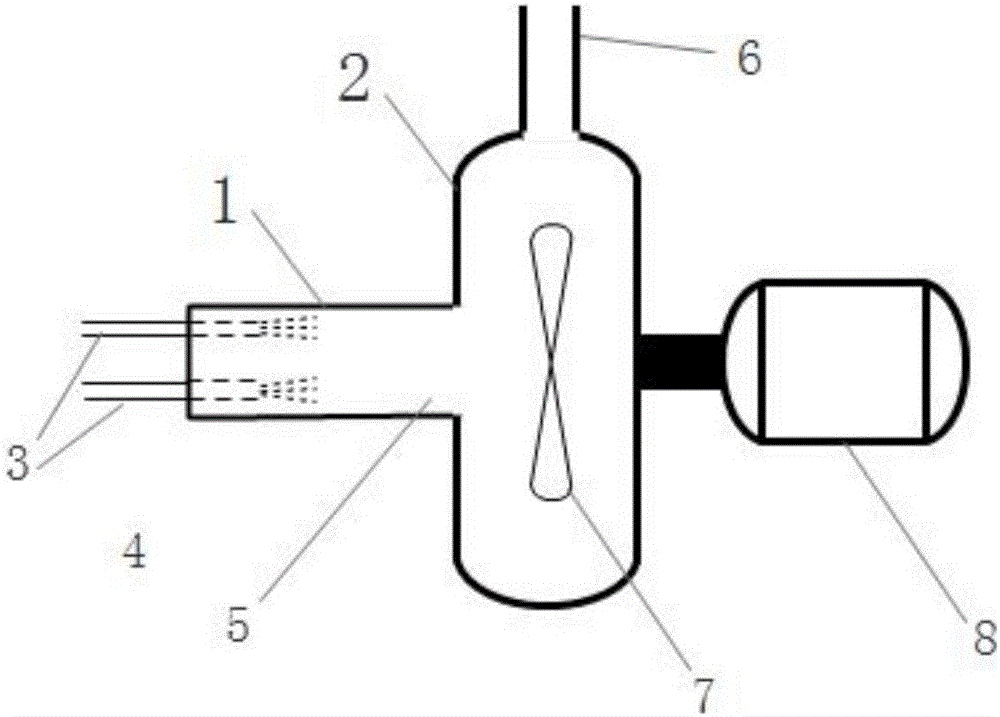

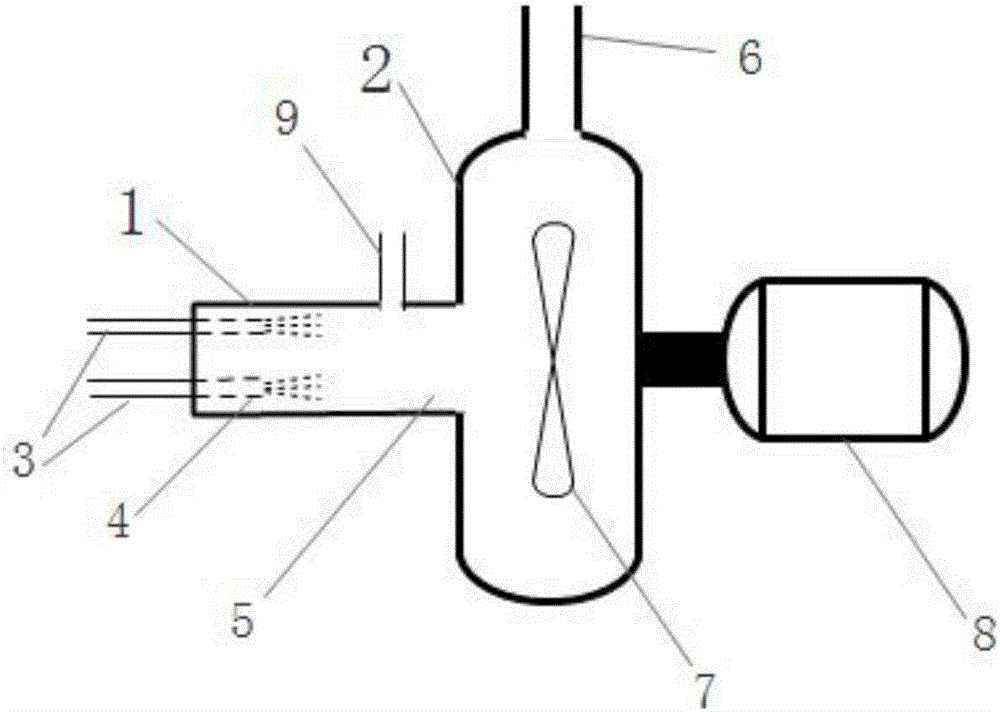

[0032] as attached figure 1 As shown, a chemical plant of the present invention includes a feed unit 1 and a stirring unit 2, the stirring unit 2 is a closed cavity with an inlet 5 and an outlet 6 of a centrifugal pump structure, and the cavity is driven by an external motor 8 The stirring impeller 7; the feeding unit 1 is tubular, one end is the feeding end, and the other end is flanged to the inlet 5 of the stirring unit 2. There are two feeding ports 3 at the feeding end of the feeding unit 1; nozzles 4 are installed at the end of each feeding port 3, and the nozzles 4 are spiral and threaded.

Embodiment 2

[0034] as attached figure 1 As shown, another chemical device of the present invention includes a feed unit 1 and a stirring unit 2, the stirring unit 2 is a closed cavity with an inlet 5 and an outlet 6 of a mortar pump structure, and there is an external motor 8 in the cavity. The stirring impeller 7; the feeding unit 1 is tubular, one end is the feeding end, and the other end is connected with the inlet 5 of the stirring unit 2 by ferrules. There are two feeding ports 3 at the feeding end of the feeding unit 1; nozzles 4 are installed at the end of each feeding port 3, and the nozzles 4 are hollow conical and connected by ferrules.

Embodiment 3

[0036] as attached figure 1 As shown, another chemical plant of the present invention comprises a feed unit 1 and a stirring unit 2, the stirring unit 2 is a closed cavity with an inlet 5 and an outlet 6 of a self-priming pump structure, and an external motor 8 is arranged in the cavity. The transmission stirring impeller 7; the feeding unit 1 is tubular, one end is the feeding end, and the other end is screwed to the inlet 5 of the stirring unit 2. The feed end of the feed unit 1 has two feed ports 3; the end of the feed port 3 is equipped with a nozzle 4, which is shower-shaped and connected by threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com