Preparation method and application of sweet potato leaf based active carbon

A sweet potato leaf, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of long electrolyte ion transmission path, low specific capacity of supercapacitor, complex internal pore structure, etc. Effects of transport and diffusion, excellent electrochemical performance, and high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

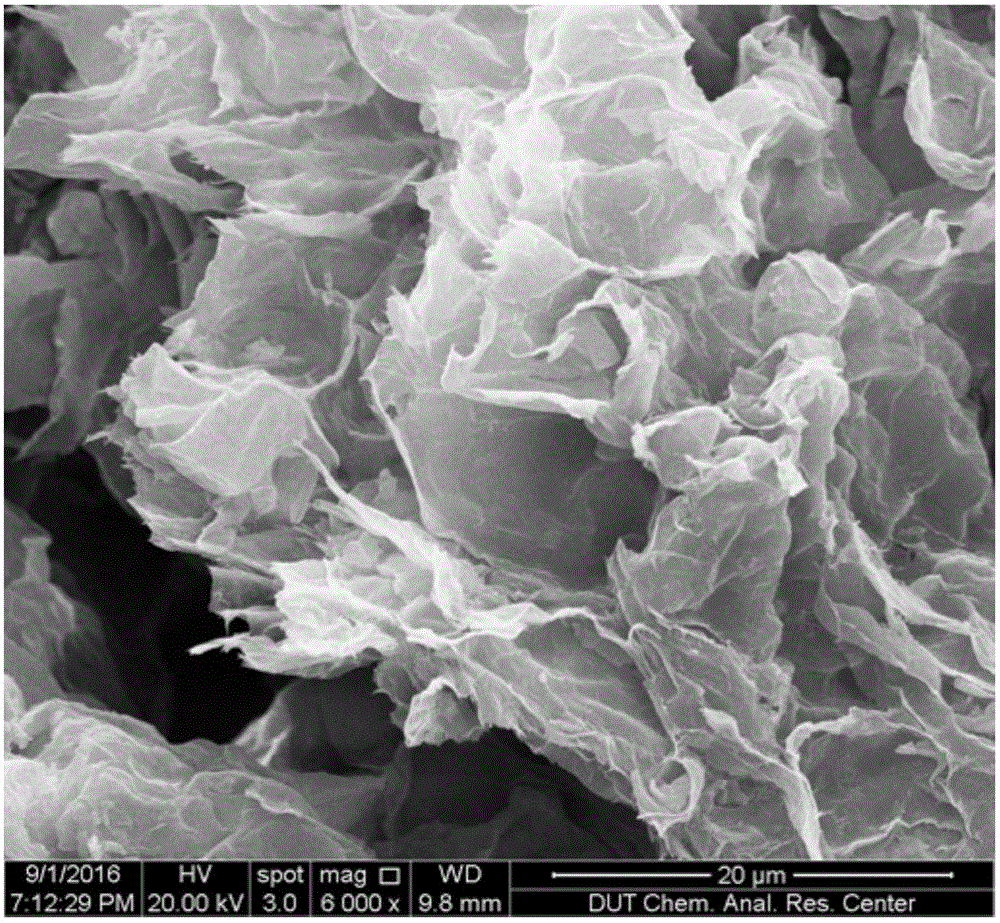

[0016] The collected sweet potato leaves were washed with deionized water multiple times to remove impurities such as sediment, dried in a blast drying oven at 120°C for 24 hours, and then crushed; 4 g of crushed sweet potato leaves were weighed and pre-carbonized under nitrogen protection. The temperature was raised from room temperature to 300 °C at a rate of 1 °C / min, kept at a constant temperature for 20 min, and cooled to room temperature to obtain a pre-carbonized product; the obtained pre-carbonized product and potassium hydroxide were added to 10 mL of deionized In water, dry in a blast drying oven at 120°C for 20 hours, and then perform high-temperature activation treatment under the protection of argon. The temperature is raised from room temperature to 600°C at a rate of 1°C / min, kept at a constant temperature for 20 minutes, and cooled to room temperature to obtain an activated product; The obtained activated product was added to 2 L of hydrochloric acid solution wi...

Embodiment 2

[0018] Wash the collected sweet potato leaves with deionized water multiple times to remove impurities such as sediment, dry them in a blast drying oven at 120°C for 24 hours, and then crush them; weigh 10 g of crushed sweet potato leaves, and perform pre-carbonization treatment under nitrogen protection. The temperature was raised from room temperature to 500°C at a rate of 5°C / min, kept at a constant temperature for 60 minutes, and cooled to room temperature to obtain a pre-carbonized product; the obtained pre-carbonized product and potassium hydroxide were added to 20 mL of deionized In water, dry in a blast drying oven at 120°C for 20 hours, and then perform high-temperature activation treatment under argon protection. The temperature is raised from room temperature to 800°C at a rate of 5°C / min, kept at a constant temperature for 60 minutes, and cooled to room temperature to obtain an activated product; The obtained activated product was added to 2 L of hydrochloric acid s...

Embodiment 3

[0020] Wash the collected sweet potato leaves with deionized water multiple times to remove impurities such as sediment, dry them in a blast drying oven at 120°C for 24 hours, and then crush them; weigh 20 g of the crushed sweet potato leaves, and perform pre-carbonization treatment under the protection of argon , the temperature was raised from room temperature to 800 °C at a rate of 15 °C / min, kept at a constant temperature for 20 min, cooled to room temperature, and a pre-carbonized product was obtained; the obtained pre-carbonized product and potassium hydroxide were added to 30 mL of Dry in ionized water for 20 hours in a blast drying oven at 120°C, and then perform high-temperature activation treatment under argon protection. The temperature rises from room temperature to 950°C at a rate of 15°C / min, keeps the temperature for 130 minutes, and cools to room temperature to obtain the activated product. The obtained activated product was added to 2L of hydrochloric acid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass specific capacitance | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com