Citric-acid-assisted Mn-dope yttrium molybdate selective-adsorption nano material and preparation method thereof

A nano-material and selective technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of easy agglomeration, low crystallinity of products, and adsorption activity of selective adsorption materials It can achieve the effect of uniform morphology, improved adsorption performance, and enhanced selective adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

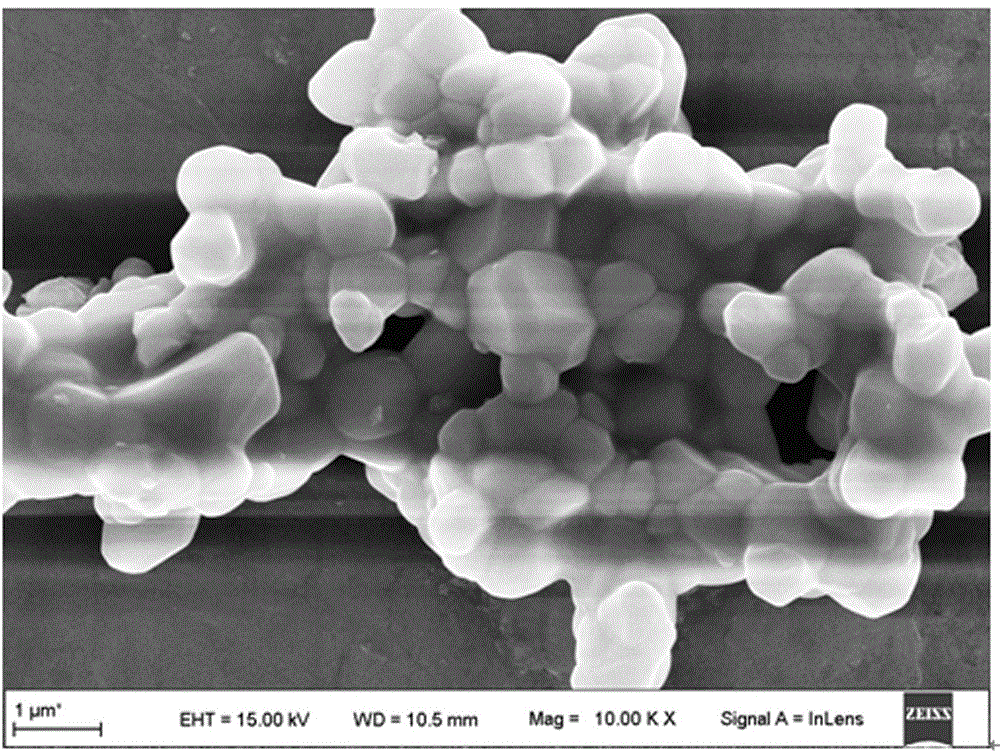

[0038] A method for preparing a citric acid-assisted Mn-doped yttrium molybdate selective adsorption nanometer material, specifically comprising the following steps.

[0039] Take by weighing 1.96mmol yttrium nitrate, 0.04mmol manganese nitrate is dissolved in 30ml distilled water, stirs to obtain solution A; Take by weighing 0.57mmol ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, A.R.) was dissolved in 30ml ethanol, and stirred evenly to obtain solution B; slowly pour solution B into solution A, stir magnetically for 1 hour, and rotate at 800r / min, then put it in a constant temperature water bath at 60°C for 12 hours, and process it into Precursor gel; add 1 g of citric acid to the precursor gel, then put it in an oven and keep it warm at 160°C for 4 hours; finally, take out the dried material and put it in a corundum crucible, and put it in a muffle furnace at a low temperature of 350°C Pre-calcine for 2 hours, and then calcined at 550°C for 3 hours to obtain nano-powde...

Embodiment 2

[0041] A method for preparing a citric acid-assisted Mn-doped yttrium molybdate selective adsorption nanometer material, specifically comprising the following steps.

[0042] Take by weighing 1.92mmol yttrium acetate, 0.08mmol manganese acetate is dissolved in 40ml distilled water, stirs to obtain solution A; Take by weighing 0.55mmol ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, A.R.) was dissolved in 30ml of methanol, and stirred evenly to obtain solution B; slowly pour solution B into solution A, magnetically stirred for 1 hour, and the rotation speed was 800r / min, and then placed in a constant temperature water bath at 80°C, and treated for 8 hours , to obtain the precursor gel; add 1 g of citric acid to the precursor gel, then put it in an oven and keep it warm for 5 hours at 150 ° C; ℃ low temperature pre-calcination for 1 hour, and then calcined at 700 ℃ for 2 hours to obtain nano-powder with selective adsorption properties.

Embodiment 3

[0044] A method for preparing a citric acid-assisted Mn-doped yttrium molybdate selective adsorption nanometer material, specifically comprising the following steps.

[0045] Take by weighing 1.88mmol yttrium acetate, 0.12mmol manganese acetate is dissolved in 50ml distilled water, stirs to obtain solution A; Take by weighing 0.55mmol ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, A.R.) was dissolved in 30ml of methanol, stirred evenly to obtain solution B; slowly poured solution B into solution A, stirred magnetically for 1.5h, and the rotation speed was 600r / min, then put it in a constant temperature water bath at 80°C for 8h, and treated into a precursor gel; add 1.5g citric acid to the precursor gel, then put it in an oven and keep it warm at 200°C for 3h; finally take out the dried material and place it in a corundum crucible, and place it in a muffle furnace for 450 ℃ low-temperature pre-calcination for 1 hour, and then calcined at 600 ℃ for 2.3 hours to obtain nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com