Working medium for heat cycle, composition for heat cycle system, and heat cycle system

A technology of working medium and circulation system, applied in the field of thermal circulation system, can solve problems such as not given, and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0220] The following examples illustrate the present invention in detail, but the present invention is not limited to these examples.

[0221] (HFO-1132 and self-decomposability test of mixed media containing HFO-1132)

[0222] The monomers of HFO-1132(Z) and HFO-1132(E) or the mixing medium obtained by mixing them with HFC-32, HFC-125, HFC-134a, HFO-1234yf in the ratio shown in Table 3 are used as For samples a to f, the self-decomposability test was carried out according to the following method.

[0223] Use an internal volume of 650cm 3 In accordance with the method based on Method A recommended as a device for measuring the combustion range of gas mixed with halogen-containing gas in the individual documents of the High Pressure Gas Security Act, the linkage of samples a to f was confirmed The presence or absence of self-decomposition reaction.

[0224] A platinum wire with an outer diameter of 0.5 mm and a length of 25 mm was fused (hot wire method) with a voltage and current of...

example 1~140

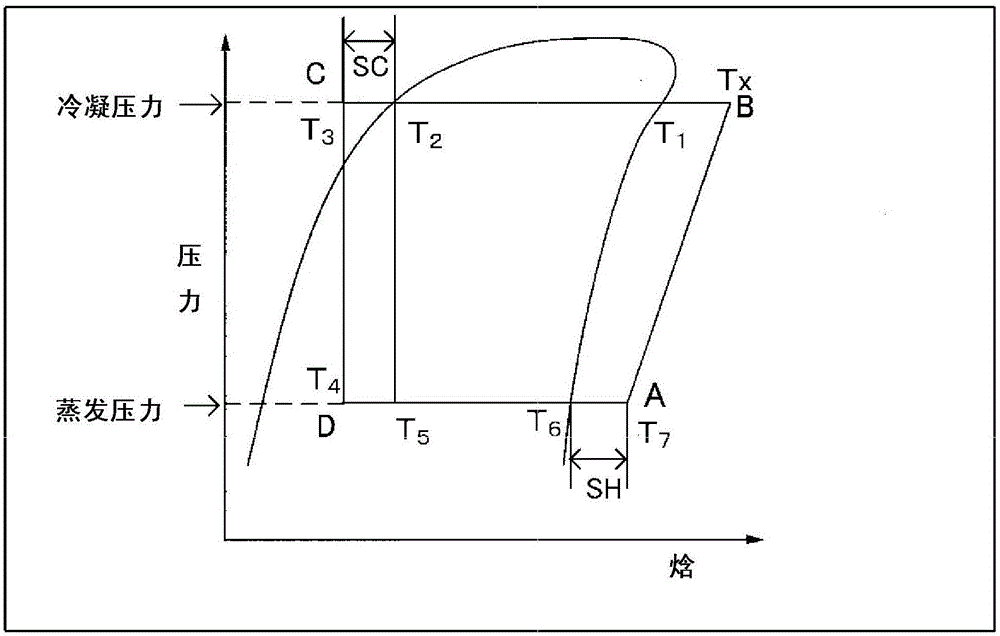

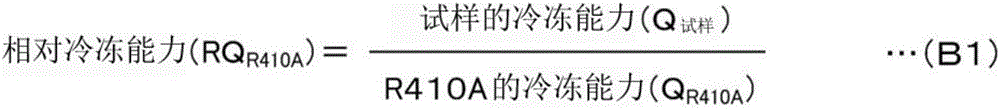

[0231] In Examples 1-70, HFO-1132 (Z) and two selected from HFC-32, HFC-125, HFC-134a, HFO-1234yf, and HFO-1234ze (E) were prepared in proportions shown in Tables 5-9 For the mixed working medium, (A) temperature gradient and relative freezing capacity (B1) RQ with respect to R410A were obtained by the above method under the temperature conditions of the above standard refrigeration cycle R410A , Relative efficiency coefficient (C1) RCOP R410A 、Relative freezing capacity (B2) RQ relative to HFC-134a R134a , Relative efficiency coefficient (C2) RCOP R134a . The results are shown in Tables 5-9.

[0232] In Examples 71 to 140, HFO-1132 (E) and two selected from HFC-32, HFC-125, HFC-134a, HFO-1234yf, and HFO-1234ze (E) were prepared in proportions shown in Tables 10 to 14 For the mixed working medium, (A) temperature gradient and relative freezing capacity (B1) RQ with respect to R410A were obtained by the above method under the temperature conditions of the above standard refrig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com