Method for preparing doped and modified nickel-cobalt lithium aluminate anode materials

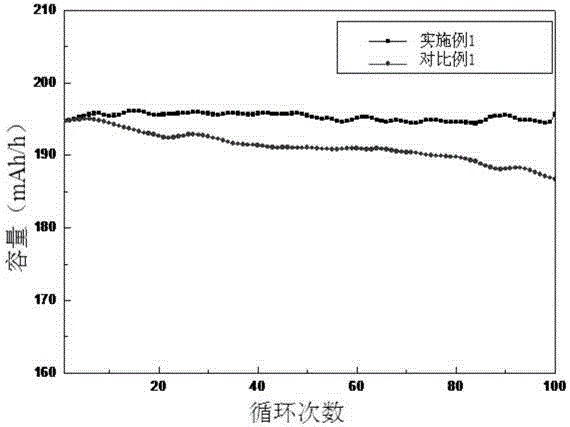

A technology of lithium nickel cobalt aluminate and cathode material, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as limited improvement range, and achieve the effects of inhibiting migration, reducing residual alkali, and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

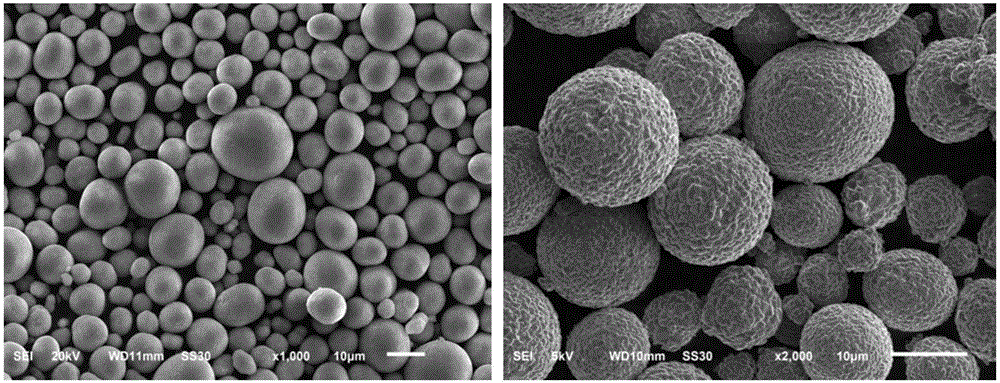

[0025] The invention provides a method for preparing a doped modified nickel-cobalt lithium aluminate positive electrode material, comprising:

[0026] (1) preparing the first mixed solution containing nickel salt and cobalt salt, the mol ratio of the nickel ion in the nickel salt and the cobalt ion in the cobalt salt is 0.80:0.15;

[0027] (2) Preparation of the second mixed solution containing aluminum salt, complexing agent and compound containing doping metal elements; said doping metal elements include at least one of titanium, zirconium and magnesium; said doping metal elements and The mass ratio of the aluminum element in the aluminum salt is 0.068-0.405:1;

[0028] (3) The first mixed solution, the second mixed solution, lye and ammonia solution are added into the reactor in parallel flow, and in the reactor, the molar ratios of the three metal ions of nickel, cobalt and aluminum are: 0.80:0.15:0.05, react at a temperature of 50°C-80°C for 36h-64h, after the reaction,...

Embodiment 1

[0058] A method for preparing a doped modified nickel-cobalt lithium aluminate cathode material, comprising:

[0059] (1) Nickel sulfate and cobalt sulfate are prepared into the first mixed solution a in the ratio of 8.0:1.5 by nickel ion and cobalt ion mol ratio, and in the first mixed solution, the total concentration of nickel and cobalt two kinds of metal ions is 100g / L; then prepare respectively the NaOH solution b with a concentration of 6mol / L and the ammonia solution c with a concentration of 10mol / L;

[0060] (2) Take 32kg of aluminum nitrate solid, 650g of titanyl sulfate, 1600g of magnesium nitrate, 1000g of lactic acid and 500ml of concentrated hydrochloric acid, stir at a constant speed for 2h, and prepare a 960L solution to obtain the second mixed solution d;

[0061] (3) A bottom liquid is set in the reaction kettle, the bottom liquid is an ammonia solution with an ammonia content of 8 g / L, the temperature of the ammonia solution is 60° C., and the pH value is ...

Embodiment 2

[0065] A method for preparing a doped modified nickel-cobalt lithium aluminate cathode material, comprising:

[0066] (1) Nickel chloride and cobalt chloride are formulated into the first mixed solution a in the ratio of 8.0:1.5 by nickel ion and cobalt ion mol ratio, and in the first mixed solution, the total concentration of nickel and cobalt two kinds of metal ions is 120g / L; Then prepare the NaOH solution b with a concentration of 8mol / L and the ammonia solution c with a concentration of 12mol / L;

[0067] (2) Take 29kg of aluminum nitrate solid, 500g of zirconium sulfate, 1000g of magnesium nitrate and 500g of disodium EDTA, stir at a constant speed for 2h, and prepare a 720L solution to obtain the second mixed solution d;

[0068] (3) The bottom liquid is set in the reactor, the bottom liquid is an ammonia solution with an ammonia content of 6g / L, the temperature of the ammonia solution is 50° C., and the pH value is 11.5. Add the above-prepared first mixed solution a, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com