MoO2-MoS2 negative electrode material of sodium-ion battery with core-shell structure and preparation method of MoO2-MoS2 negative electrode material

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as poor cycle stability, capacity fading, poor conductivity, etc., and achieve high repeatability, large yield, and cycle time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

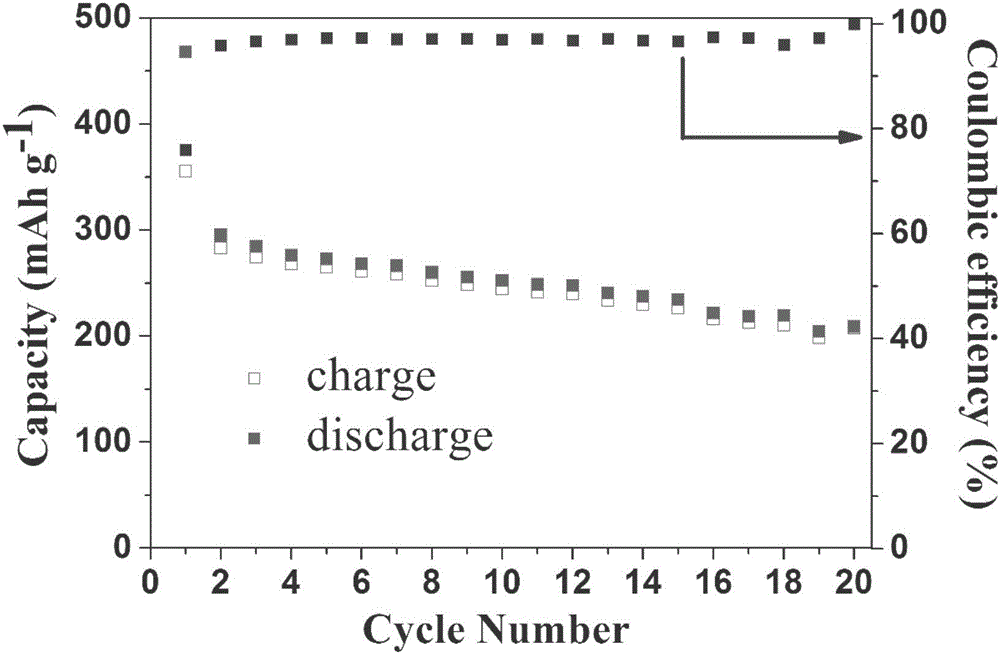

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

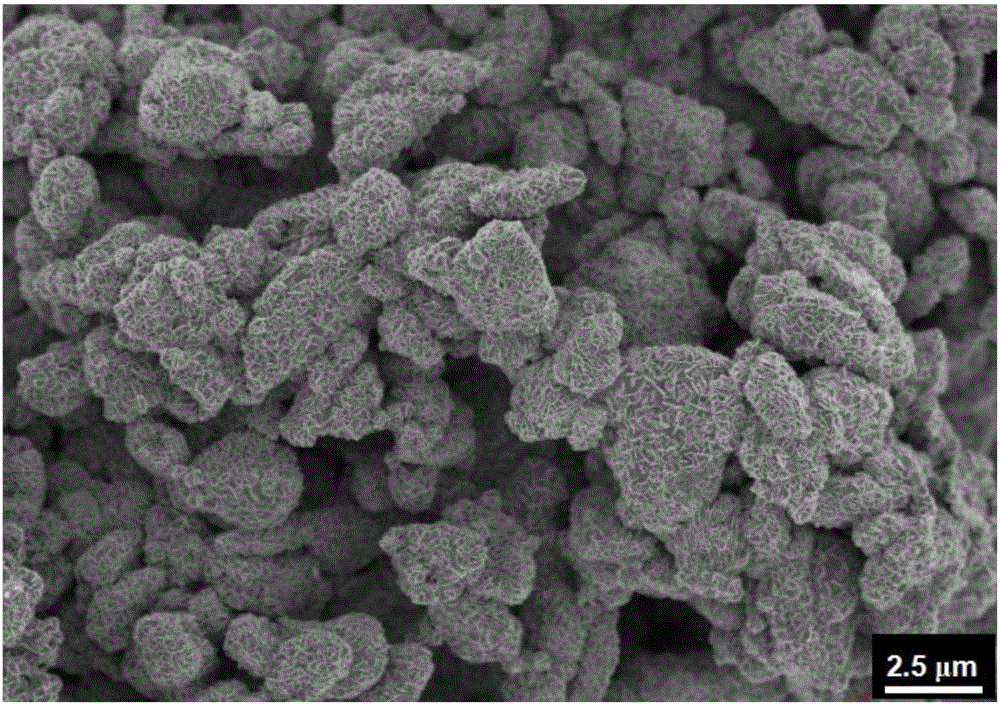

[0024] A core-shell structure MoO disclosed by the invention 2 -MoS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0025]Step 1. Take ammonium molybdate, grind it evenly, raise the temperature from room temperature to 400-600°C for 1-3 hours, then cool to room temperature, wash and dry the reaction product to obtain MoO 3 Precursor;

[0026] Step 2. Put MoO 3 Precursor and S powder according to the mass ratio of 0.5: (1.0 ~ 5.0), after uniform grinding, under inert conditions, from room temperature to 400 ~ 600 ℃, heat preservation reaction 0.5 ~ 2h, and then continue to heat up to 600 ~ 800 ℃, Insulate and react for 0.5 to 2 hours, cool to room temperature, wash and dry the reaction product to obtain MoO with a core-shell structure 2 -MoS 2 Sodium ion battery anode material.

[0027] Since the sublimation of sulfur powder in the reaction process exists in the form of gas and reflects the environment, ...

Embodiment 1

[0032] A kind of core-shell structure MoO 2 -MoS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0033] 1. Precursor MoO 3 preparation of

[0034] 1) Take ammonium molybdate, put it into a mortar and grind it thoroughly. The ground sample was placed in a porcelain boat and heated in a tube furnace at 5°C min -1 The heating rate was increased to 400 °C, and after 1 hour of heat preservation, MoO was obtained by high-temperature cracking under air atmosphere conditions. 3 ;

[0035] 2) Cool to room temperature after the reaction, wash the product 3 times with deionized water, and dry it in vacuum for 8 hours to obtain pure phase MoO 3 Precursor.

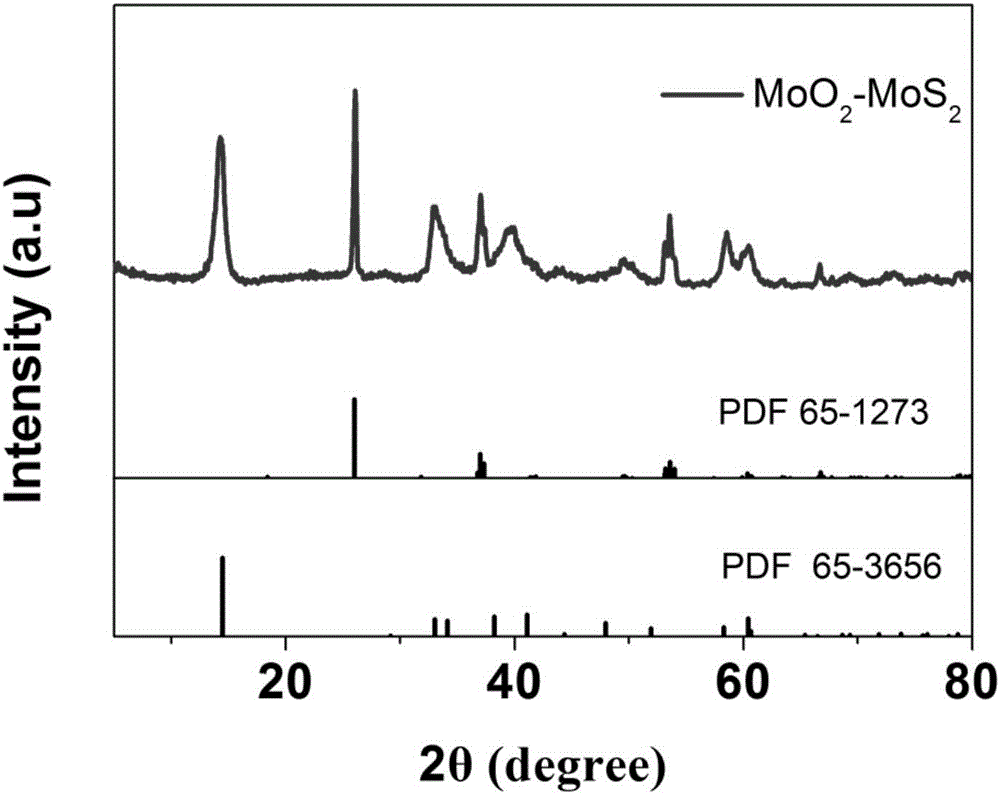

[0036] 2. MoO 2 -MoS 2 preparation of

[0037] 1) Take the precursor MoO 3 and S powder m(MoO 3 :S)=0.5:1.0 ratio, make it mix evenly by grinding, place the sample after grinding in the porcelain boat, react under the argon atmosphere condition of tubular ...

Embodiment 2

[0045] A kind of core-shell structure MoO 2 -MoS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0046] 1. Precursor MoO 3 preparation of

[0047] 1) Take ammonium molybdate, put it into a mortar and grind it thoroughly. The ground sample was placed in a porcelain boat and heated in a tube furnace at 6°C min -1 The heating rate was increased to 400°C, and after 1.5h of heat preservation, the high-temperature pyrolysis under air atmosphere conditions gave MoO 3 ;

[0048] 2) Cool to room temperature after the reaction, wash the product 4 times with deionized water, and dry it in vacuum for 9 hours to obtain pure phase MoO 3 Precursor.

[0049] 2. MoO 2 -MoS 2 preparation of

[0050] 1) Take the precursor MoO 3 and S powder m(MoO 3 :S)=0.5:2.0 ratio, make it mix uniformly by grinding, place the sample after grinding in a porcelain boat, and react under the argon atmosphere condition of the tubular a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com