Processing system for decreasing viscose particle number in spinning technology

A processing system and spinning process technology, which is applied in the field of processing systems to reduce the number of viscose particles in the spinning process, can solve the problems of filter channel blockage, spinneret blockage, wool filament winding and other problems, and achieve reduction of viscosity The effect of reducing the number of colloidal particles, reducing the number of particles, and improving the uniformity of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

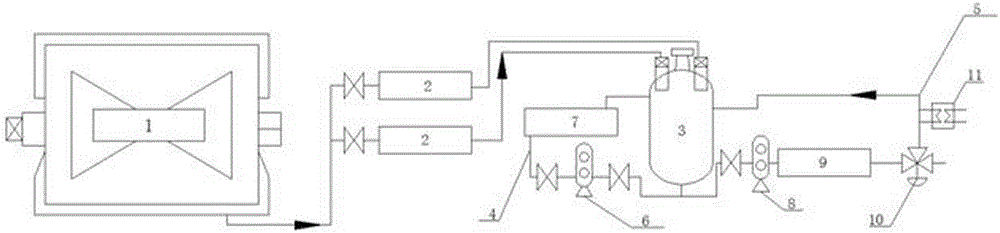

[0020] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0021] A treatment system suitable for reducing the number of viscose particles in the spinning process, comprising a yellowing machine 1, a coarse grinder 2, a dissolving barrel 3, a dissolving barrel internal circulation device 4 and a dissolving barrel external circulation device 5; the yellowing The machine 1 is connected with the coarse grinder 2, and the alkali cellulose after yellowing is transported into the coarse grinder 2 for coarse grinding; the coarse grinder 2 is connected with the dissolving barrel 3, and the alkali cellulose after the coarse grinding is transported into the The dissolving barrel 3 dissolves; the circulating device 4 in the dissolving barrel is connected to the dissolving barrel 3, and one end of the circulating device 4 in the dissolving barrel is connected to the bottom of the dissolving barrel 3, and the other end is ...

Embodiment 2

[0024] As another preferred embodiment of the present invention, refer to the attached figure 1 , this example discloses:

[0025] A treatment system suitable for reducing the number of viscose particles in the spinning process, comprising a yellowing machine 1, a coarse grinder 2, a dissolving barrel 3, a dissolving barrel internal circulation device 4 and a dissolving barrel external circulation device 5; the yellowing The machine 1 is connected with the coarse grinder 2, and the alkali cellulose after the yellowing is transported into the coarse grinder 2 for coarse grinding; the coarse grinder 2 is connected with the dissolving barrel 3, and the alkali cellulose after the coarse grinding is transported into the The dissolving barrel 3 dissolves; the circulating device 4 in the dissolving barrel is connected to the dissolving barrel 3, and one end of the circulating device 4 in the dissolving barrel is connected to the bottom of the dissolving barrel 3, and the other end is...

Embodiment 3

[0028] As another preferred embodiment of the present invention, refer to the attached figure 1 , this example discloses:

[0029]A treatment system suitable for reducing the number of viscose particles in the spinning process, comprising a yellowing machine 1, a coarse grinder 2, a dissolving barrel 3, a dissolving barrel internal circulation device 4 and a dissolving barrel external circulation device 5; the yellowing The machine 1 is connected with the coarse grinder 2, and the alkali cellulose after yellowing is transported into the coarse grinder 2 for coarse grinding; the coarse grinder 2 is connected with the dissolving barrel 3, and the alkali cellulose after the coarse grinding is transported into the The dissolving barrel 3 dissolves; the circulating device 4 in the dissolving barrel is connected to the dissolving barrel 3, and one end of the circulating device 4 in the dissolving barrel is connected to the bottom of the dissolving barrel 3, and the other end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com