A method for reducing the number of impurity particles in metal layer sputtering process

A technology of metal layer and sputtering, which is applied in metal material coating process, sputtering coating, coating, etc., can solve the problem of increasing the adhesion between metal titanium and titanium nitride, not mentioning the yield rate of metal bumps, increasing Manpower and material costs and other issues, to achieve the effect of reducing the generation rate of impurity particles, reducing labor and material costs, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

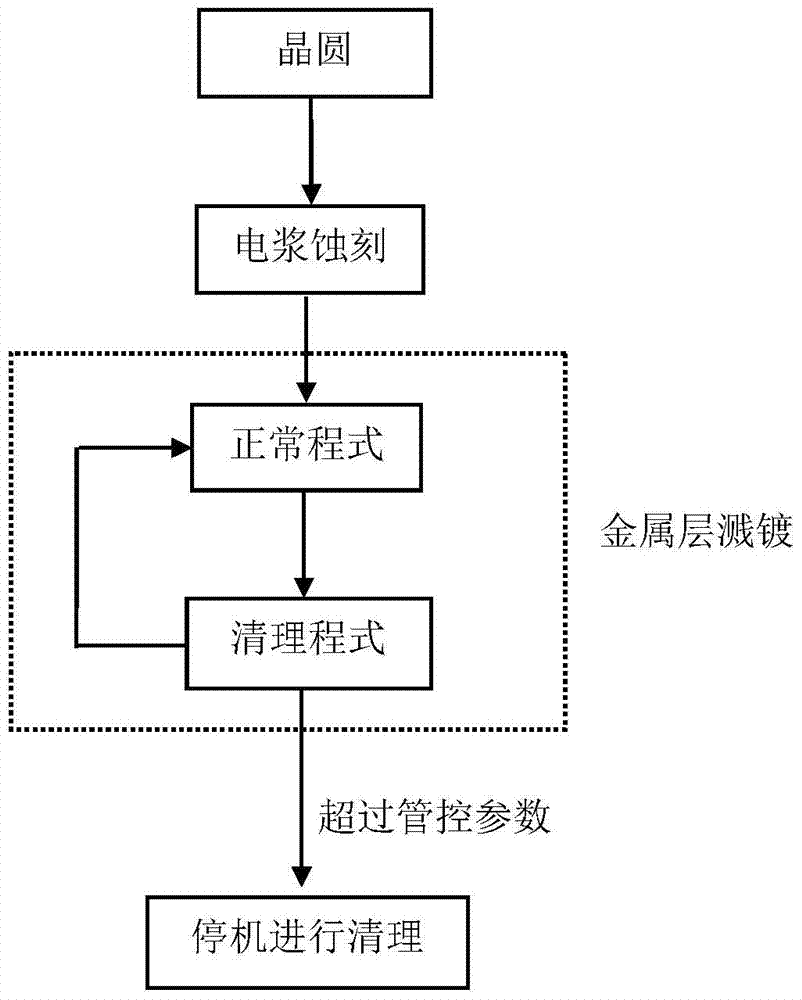

[0023] Now in conjunction with the metal layer sputtering process and the plasma etching process, the technical scheme of the present invention is described in detail. The metal layer sputtering is to input an inert gas (such as argon) under vacuum conditions. Under the effect of high-voltage direct current, the argon is Ionization, argon ions hit the metal source (target), sputter out metal atoms, deposit and attach to the plated part, that is, form a metal layer.

[0024] Before the metal layer is sputtered, the plasma etching process must be carried out. There are usually two high-frequency power sources in the cavity of the plasma etching; one is a 2.0MHz microwave (Microwave) power supply, and the other is a 13.6MHz radio frequency (RF) power supply. )power supply. The microwave power supply exists above the plasma etching chamber (far away from the wafer), and its function is mainly to generate a plasma source (generating positively charged argon ions), while the main pu...

Embodiment approach 2

[0050] A method for reducing the number of impurity particles in a metal layer sputtering process, comprising the following steps: (1) turning on a microwave power supply and a radio frequency power supply, and performing plasma etching on a wafer surface and a metal pad surface; Metal layer sputtering on the wafer; (3) Set the upper limit parameter of particle number control, and stop the machine to clean the inner wall of the plasma etching chamber when this value is exceeded;

[0051] in,

[0052] The metal pad described in the step (1) is a gold pad, or a copper pad, or an aluminum pad; the plasma gas used in the plasma etching is argon;

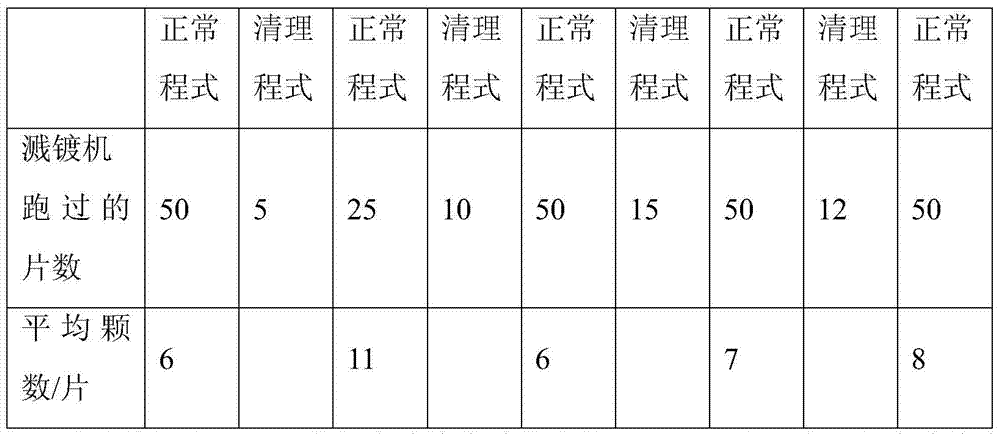

[0053] Metal layer sputtering process comprises normal program and plasma etching cleaning program in the step (2);

[0054] The method adopted in the plasma etching cleaning program in the metal layer sputtering process described in step (2) is: turn off the radio frequency power supply, and use the plasma generated by the microwave po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com